Thermal simulation can reduce development & deployment costs

Tom Gregory of Future Facilities explains how thermal simulation can reduce electronic product and system development and deployment costs. As he does so, he reveals how the integration of greater intelligence and automation into thermal modelling tools is delivering real benefits to a growing number of engineers.

2014 has seen a continued trend for demands on electronic system designers to deliver products that meet a multitude of tough goals. In particular, the average product developer now has to deliver products that are more energy efficient, that deliver increased levels of functionality, that boast better performance and that are more and more miniaturised. The challenges presented by these numerous conflicting demands are various, but perhaps the toughest that the product developer faces is whether or not they’ll be able to remove excess heat from their designs. The answer lies in the use of thermal simulation software.

Thermal modelling tools allow engineers to accurately predict and assess the thermal performance of their designs, and to verify the best way to efficiently manage the heat the equipment generates. Moreover, they enable the engineer to acquire a concrete understanding of the temperature distribution in a given design, and can be used not only to fine-tune designs, but also to enable the creation of products that are smaller and more reliable.

There are many situations where decreasing the junction temperature of some electronic components reduces electrical losses, while others suffer badly in terms of reliability and performance. To counter this, leading engineering teams use thermal modelling tools to assess intra-system thermal performance accurately and quickly. In short, these tools enable the teams to significantly cut product development time. How? By reducing design iterations, and by ensuring that a final product operates within its required thermal parameters, thereby enhancing operating life and reliability.

Thermal simulation also enables significant cost savings and return-on-investment by reducing project delays and negating the need for a redesign of product enclosures or PCBs. Similarly, by discovering thermal problems before product release, simulation reduces the likelihood of product recalls.

Overall, thermal simulation tools have been proven to make the difference between a successful and timely release to market and a missed opportunity. However, not all thermal simulation tools were born equal, and understanding the benefits and trade-offs of thermal simulation technology are key to making the right purchasing decision for your company.

Applications

Thermal simulation can be employed in multiple applications across many diverse markets. In mobile devices for consumer markets, the temperature of components such as microprocessors can rise by more than 30°C in a matter of seconds when handling computationally intense workloads, and then quickly go down again with large elements of the device at least reverting back into low-power or sleep mode. Thermal simulation helps in the system design to manage these sudden changes.

A second example is in data centres, where forced-air cooling is responsible for a significant part of the cost of running a facility. Better understanding of the heat flow through a system can lead to designs that enable lower fan speeds, thereby reducing overall energy consumption. And thermal issues can be even more challenging in automotive as excess heat can significantly reduce reliability, possibly leading to vehicle recalls. HEVs for example require high-density power electronics, which can be a major challenge especially considering that power devices can dissipate tens or even hundreds of watts of waste heat.

Thermal simulation is essentially a specialisation of the technology developed for Computational Fluid Dynamics (CFD), which uses the Navier-Stokes flow equations for viscous and heat-conducting fluids to model the flow of fluids through and around objects. To enable the simulation of a system or object, its construction needs to be represented as a mesh of grid cells; and the quality of this grid is crucial to achieving an accurate solution.

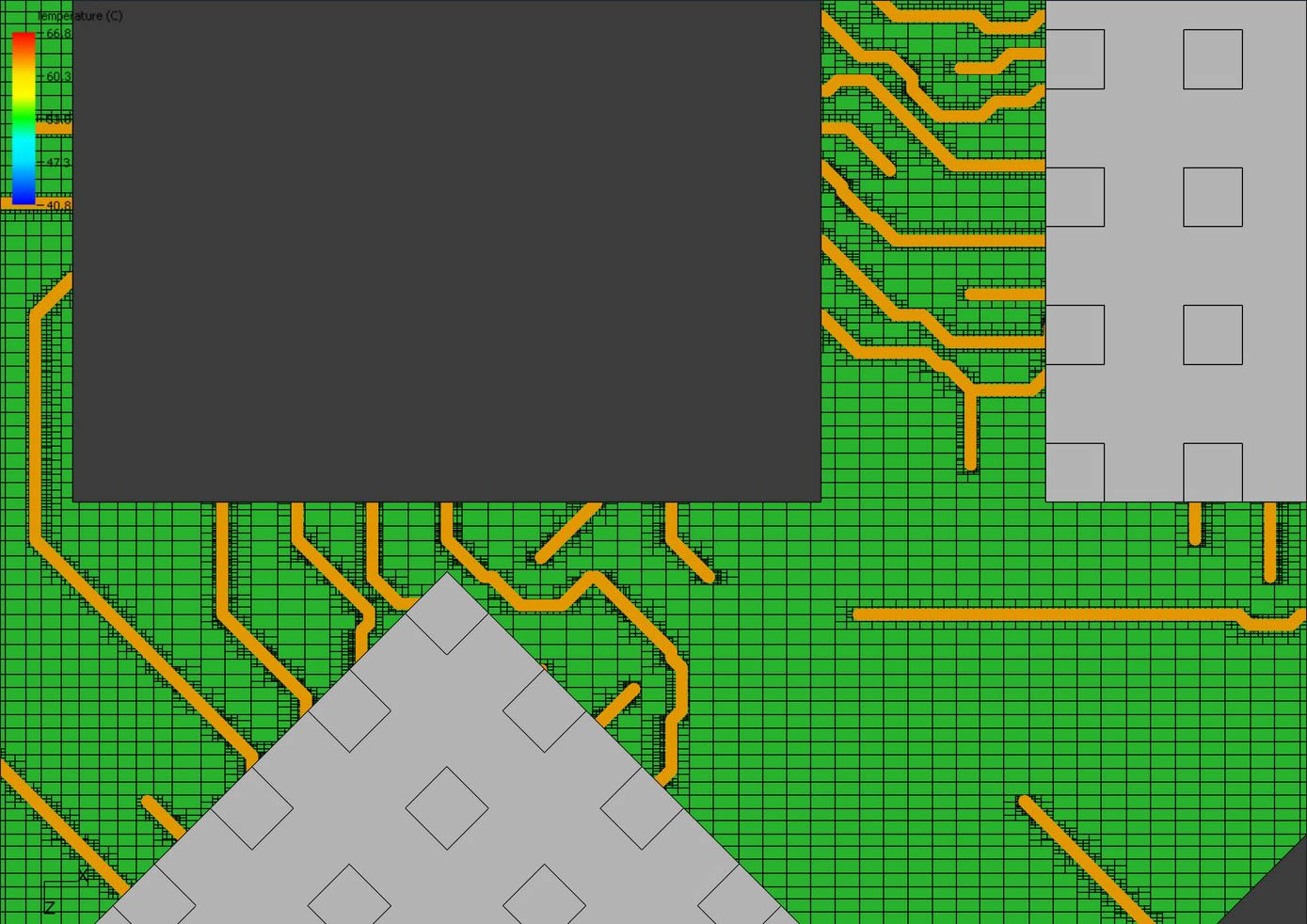

Traditional implementations of simulation have not always been able to cope with the ever-increasing complexity of highly integrated electronic designs, often leading to inaccurate results through over-simplification. If a grid is too finely detailed, it will take much longer to calculate and may not even fit into the memory of the simulation computer. Conversely, if the grid is simplified to use a more coarse-grained structure, there can be a significant impact on the accuracy of the simulation. Engineers usually have to manually alter the resolution to focus on those parts of the design that are thought to be thermally significant, which is a time consuming and complex process.

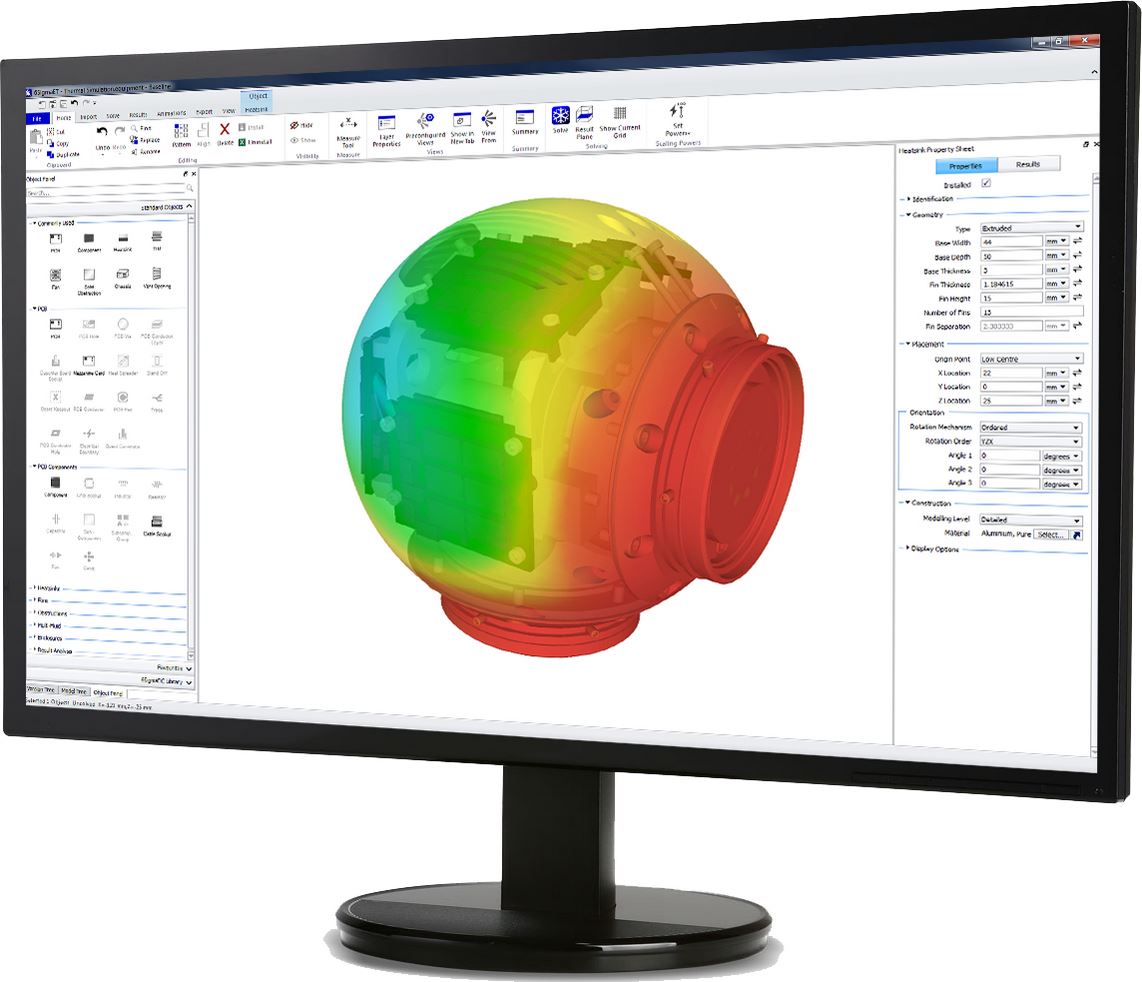

The key to effective simulation is to provide a better way of optimising the grid to provide both performance and accuracy. 6SigmaET is a thermal modelling tool that has been designed specifically for the electronics industry and the latest version, Release 9 (R9), brings a new level of productivity to electronics cooling design.

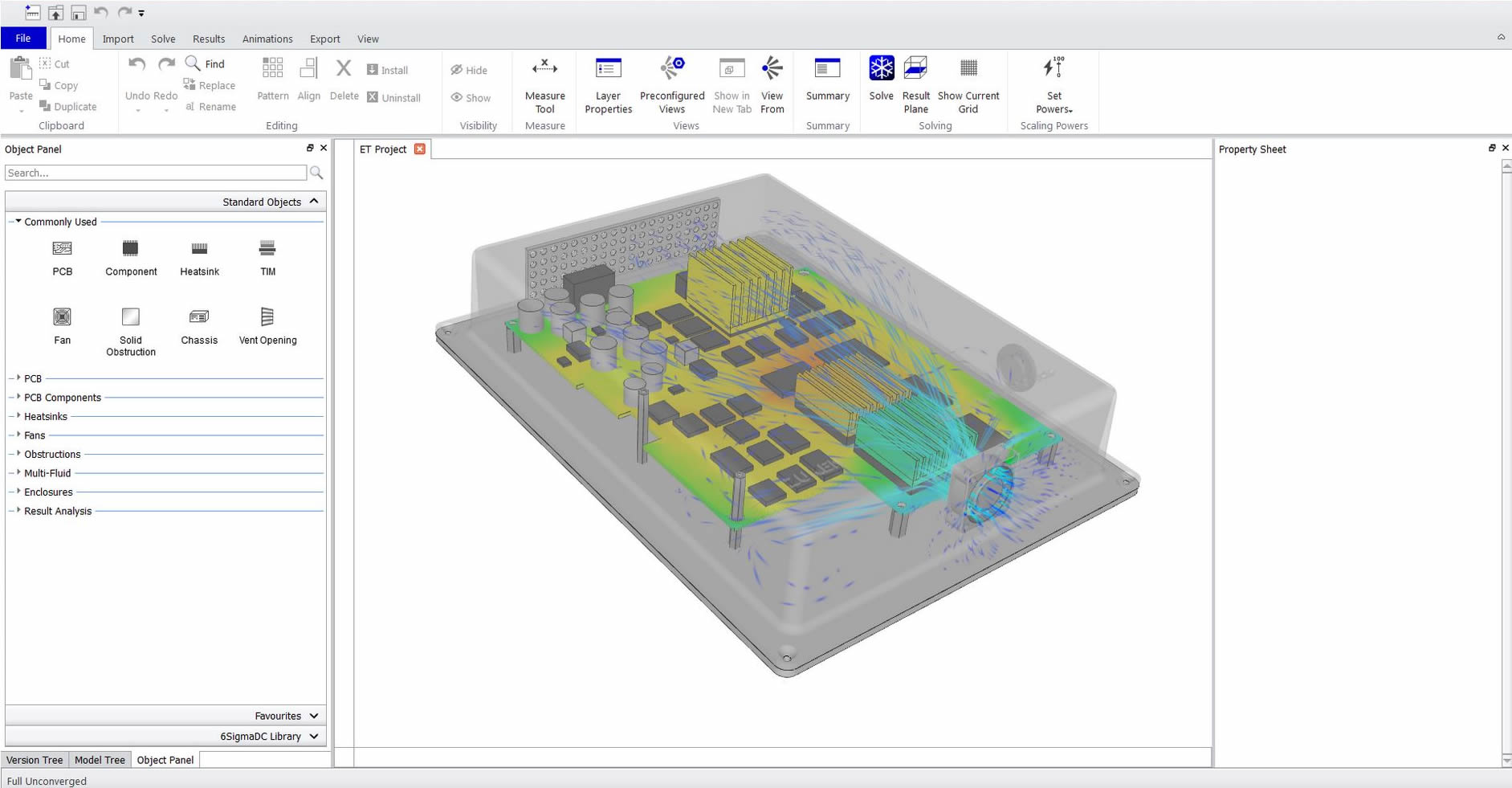

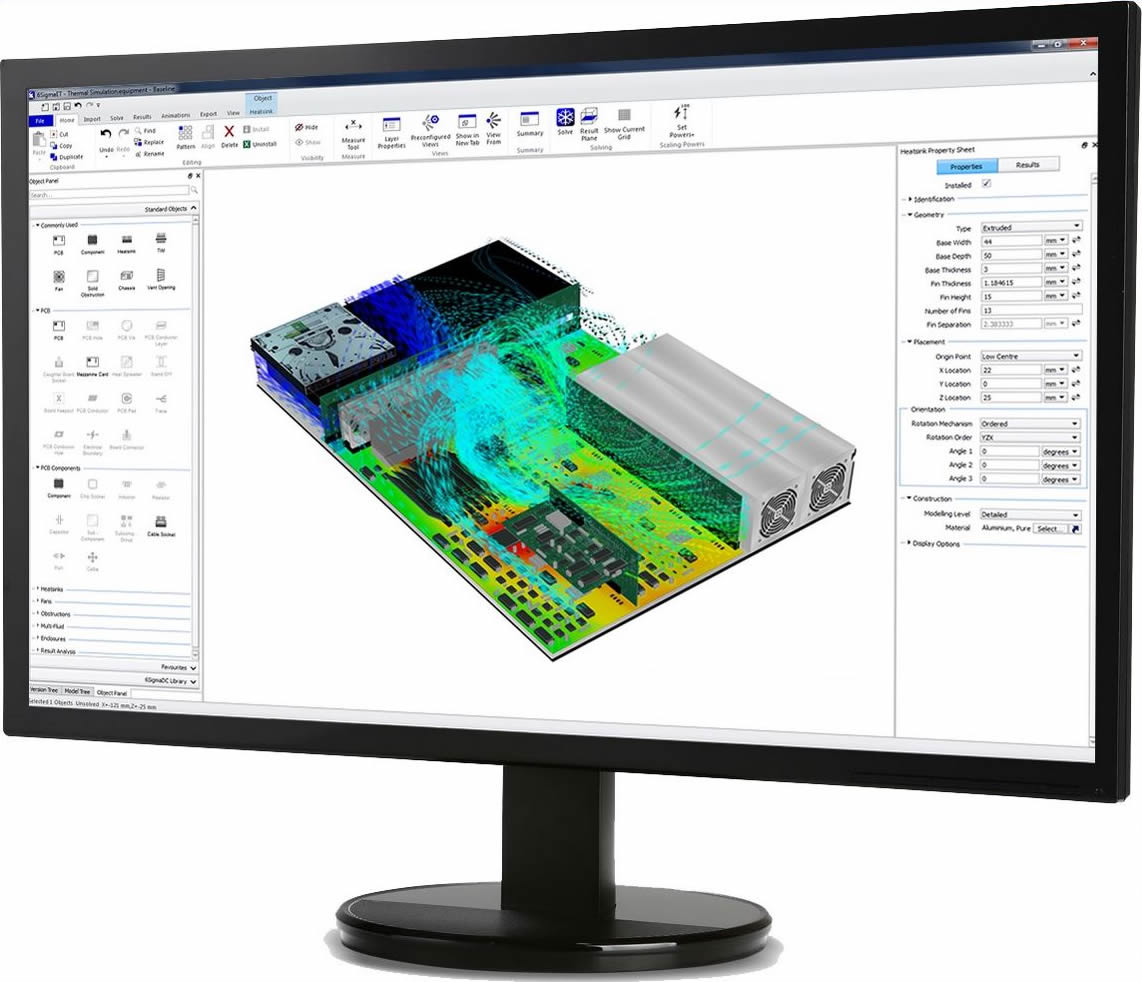

6SigmaET R9 integrates new levels of automation, intelligence and ease of use to overcome many of the problems that have plagued analysis tools in the past: it also now makes the technology accessible to a much broader community of design engineers and not just specialists in thermal simulation. In terms of automation, for example, built-in grid-generation rules automatically ensure use of the optimum grid, and smart objects come with rules that automatically place, align, collision detect and also error check. The tool incorporates object-based gridding with predefined gridding rules automatically deciding the best grid for the simulation, relieving the user from the burden of having to manually optimise the grid.

The new multi-level unstructured staggered grid solver avoids many problems associated with alternative unstructured techniques. Starting with a fine grid over the whole model, a hierarchy of increasingly coarse Cartesian grids is constructed and the tool’s solver selects from these only those cells necessary to resolve the geometry. This ensures that large areas that do not call for highly detailed grids are treated at a suitable level of resolution, but still allow the tool to select a finer grid for smaller objects. In the past, resolving all the copper traces on a PCB model may have required nearly 1bn cells, whereas the Release 9 6SigmaET solver only requires 6m cells to achieve the same level of resolution, achieving a solution in only minutes; and a ten-fold decrease in solve time has been demonstrated for many designs.

In addition, in terms of computing power, the 6SigmaET solver is an extremely fast and robust distributed-memory parallelised tool and therefore takes full advantage of multicore processing; capable of solving models in excess of 300m grid cells.

Ease of use

A wide range of intelligent modelling objects including PCBs, chip sockets and electronic components are available in 6SigmaET. For example, the tool is capable of modelling semiconductor devices, either imported from CAD models or configured parametrically, to achieve the accurate prediction of junction temperatures, as well as enabling the import and analysis of complex heat sink and enclosure designs.

The tool also has a number of user-interface and functionality enhancements such as a new object panel that displays all available intelligent modelling objects and allows them to be dragged and dropped into the model. The latest version also offers a context-sensitive and ribbon-based user interface, replacing the traditional menus and toolbars of older-generation products. In addition, the tool also features automated revision control and design-timeline tracking to enable designers to organise design variations and track design progress from concept to production.

Improvements to grid and solver algorithms, as well as modelling enhancements within increasingly easy-to-use tools such as 6SigmaET, are now enabling the use of thermal modelling in impossible-to-solve applications that were simply impossible or impractical with traditional thermal modelling. Overall, tools such as 6SigmaET are enabling an increasing range of product and system architects in many diverse markets to deal more effectively with the heat being created in next-gen systems.