CT inspection advances production of 3D printed medical implants

Lithuanian medical company, Ortho Baltic is the first manufacturer of patient-specific, temporomandibular joint endoprostheses in the Baltic States and one of only three in Europe. The implants replace loss or lack of functionality of jaw movement. To underpin their production, the firm invested in 2012 in Additive Manufacturing (AM) technology and recently acquired CT (Computed Tomography) inspection equipment from Nikon Metrology for quality control.

In its mission statement, Ortho Baltic cites two objectives: to move away from a ‘one implant fits all’ mind-set towards tailored solutions; and to make patient-specific implants affordable and readily available for all patients and national healthcare systems. It also designs and produces patient specific joints, cranial and spinal implants, bone plating systems, dental and jaw restoration implants and surgical guides.

The Implant Design and Development Centre uses various AM processes for the different types of components produced. Typically, implants are made from medical Grade-5 titanium alloy Ti6Al4V by direct laser metal sintering. For its surgical guides and implant models, a biocompatible polymer PA 2200 (also known as Nylon-12) is selective laser sintered.

X-ray plays an important role in the process from start to end. Medical CT scans are the basis for preparing the CAD model, while inspection of AM parts is carried out with a Nikon Metrology industrial, high voltage, micro-CT scanner.

Milda Jokymaitytė, Clinical Engineer at Ortho Baltic explained: “To create anatomical models, 3D reconstruction engineers use the patient’s radiological data to perform a 3D reconstruction. The anatomical bone structures are segmented and virtual 3D models prepared.

“Including printing, quality control, packaging and sterilisation, the usual lead-time for a patient-specific jaw joint implant is approximately four weeks following the surgeon’s approval of the final design. From this point onwards, pre-surgical planning commences between patient and surgeon, ultimately leading to surgery completion.”

An important challenge is the quality assurance of AM components. Especially in the medical field, the quality, fit and functionality of implants and other medical components is vital. Domantas Ozerenskis, Product Quality Manager at Ortho Baltic explained: “Currently, micro-CT is the best solution for our product development and quality control. 3D-printing is a complicated technology and there is a large variety of processing parameters, so it is very hard to predict the quality and geometry.”

The CT scanner at Ortho Baltic

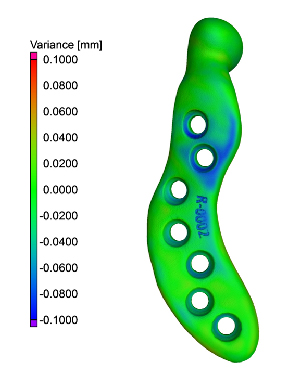

The Nikon Metrology XT H 225 micro-CT scanner for quality inspection at Kaunas has a 225kV micro-focus source that reveals non-destructively any voids, cracks and other defects of the complex internal features of the AM components. The scan data is compared against the original CAD design to reveal any deviations.

Mr Ozerenskis added: “Micro-CT scanning is the only way to check non-destructively for voids and cracks inside a part.

“We considered a coordinate measuring machine, but it is inconvenient for taking non-parametric measurements and there is no possibility for inner structure investigation.

“The internal quality of implants is very important, as it determines the mechanical strength of the part.”

Ortho Baltic needed at least a 200kV energy source to penetrate the dense materials it uses. Another requirement was for the system to have a large enough working area, as component sizes vary for each patient and procedure, so a platform capable of holding a range of large or heavy components was needed.

The Nikon Metrology XT H 225 was suitable in this respect and led to the medical company opting for the machine, together with a Varian 4030 digital panel and Inspect-X software.

The CT system is helping Ortho Baltic to make tailored implants affordable and easily available. In comparison to standard implants previously sourced from the USA, the firm has been able to produce its implants to the same high quality at almost half the cost. Maxillofacial surgeon S. Bojarskas affirmed: “Apart from needing more extensive planning, the AM product itself is no different in terms of quality.”

Ozerenskis concluded: “Nominal CAD to actual 3D printed implant comparison, geometry inspection and void detection are irreplaceable for our quality control. The Nikon solution offers better knowledge of what we are manufacturing and gives superior precision and understanding of 3D printing errors and deviations.

“After 3D metal printing, post-processes such as sandblasting and polishing often remove thick surface layers up to 200µ – even more in the case of other manual processes. What micro-CT data has also helped to do is adjust our CAD and 3D printing protocols to get the most accurate geometry for all our AM parts”.