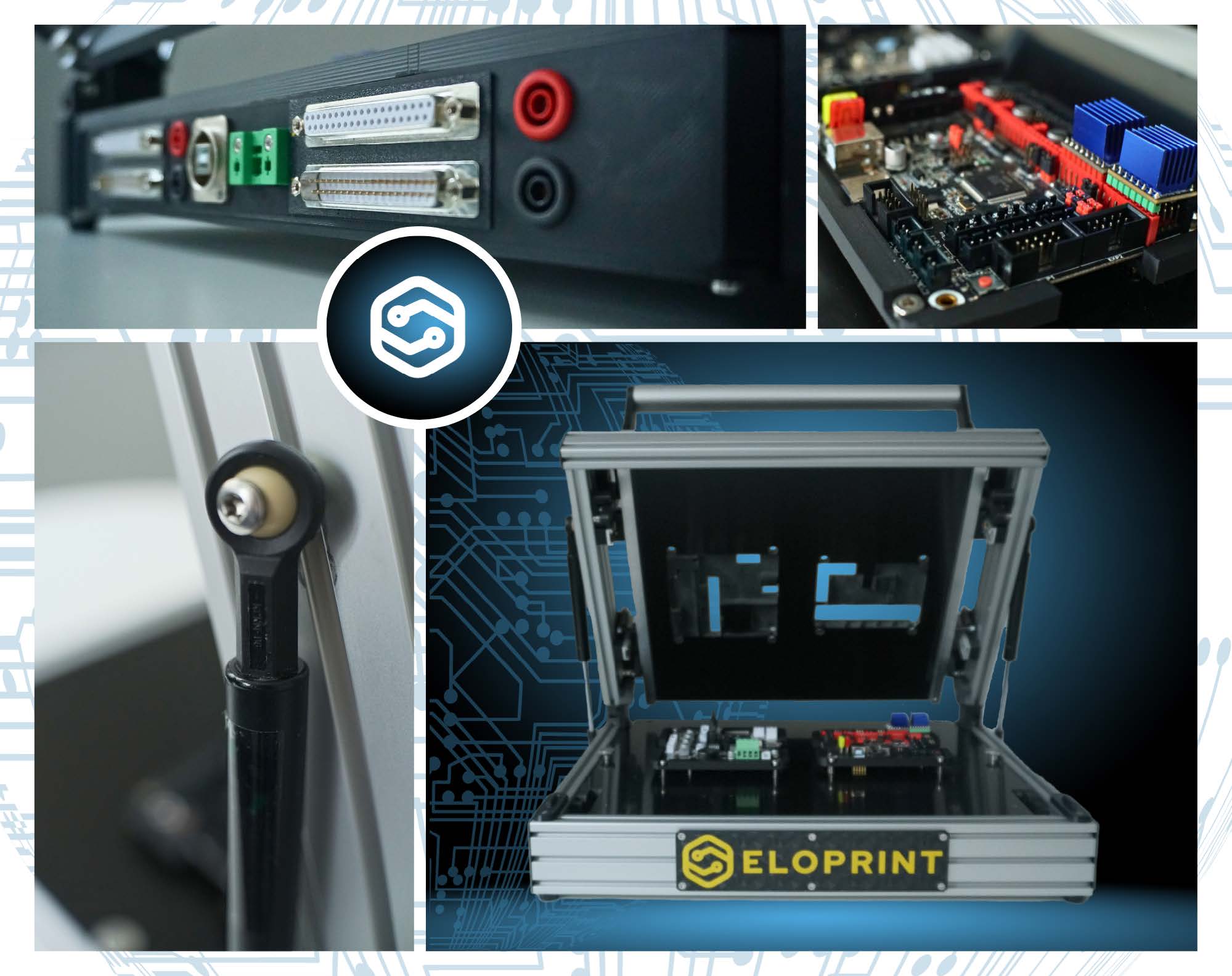

New PCB test adapter: a robust and scalable solution

The ELOPRINT company is known for manufacturing individual test adapters using additive manufacturing methods. The test adapters are comparatively compact, inexpensive, and can be delivered at short notice.

ELOPRINT is expanding its product range to include the robustness-optimised IDL product line, which complements the already established BAL, PRL, and POL product lines.

While ELOPRINT's previous test adapters are optimised for manufacturability using different additive manufacturing technologies, the IDL is characterised by a stable frame made of aluminium strut profiles, which forms the basic structure of the system and ensures stability and scalability. The IDL is available in two standard sizes with a maximum test area of 200*200mm and 300*300mm respectively, covering a wide range of PCB sizes. It was also designed so that it can also be manufactured in special sizes.

Inside the adapter, the CNC-milled needle bed ensures an exact arrangement of the test needles, which enables reliable electrical contact of even the smallest test points. A spring-loaded carrier plate protects the needles when the test specimen is inserted and ensures their longevity.

The test adapter has a locking mechanism that changes from a rotating to a linear movement. Due to the rotating movement, the hold-down device folds backwards when open so that the test specimen can be inserted without hindrance. When closing, the upper frame first folds down before changing into a linear movement and gently pressing the test specimen onto the test contact pins.

The mechanism also locks on the front when closing, which prevents the hold-down device from bending upwards, even under high contact pressure. This allows contacting up to 1,000 test points.

The circuit board can be precisely aligned either using its external geometry or using catch pins. To protect the test contact pins, it is first placed on a spring-loaded support plate when inserted and only comes into contact with the test pins when the adapter is closed.

Optionally, a second needle bed can be integrated instead of the hold-down device for double-sided contacting.

The electrical interface to the measuring electronics can be individually specified and is firmly connected to the needle bed. There is no additional internal transfer interface between the needle bed and the connector panel. This reduces complexity, increases signal integrity, and offers the possibility of defining individual interfaces to the measuring electronics for different needle bed applications.

The IDL is characterised by its user-friendly features. Tool-free exchange of the needle bed and hold-down device allows for quick configuration, while the ability for double-sided contacting expands the range of testing options. It is also possible to integrate any components such as sensors, switches, display elements and switching contact pins into the adapter to detect the presence of the test object. This ensures maximum flexibility for different application scenarios.

The ELOPRINT team specialises in being available at short notice, answering questions and completing even complex projects in just a few weeks.