Evaluating battery cell quality in electric vehicles

The automotive industry is undergoing a monumental shift towards electrification, with batteries at the forefront of this transformation. No component in the history of car technology has such a profound influence on the finished result while undergoing its own rapid speed of advancement.

Testing batteries presents unique challenges as they incorporate both electromechanical elements and chemistry. This dual nature demands a testing approach that encompasses not only electrical and mechanical assessments but also a deep understanding of the electrochemical processes integral to a battery’s functionality, safety and operational lifetime.

In many ways, testing a battery is similar to checking the health of a human body. Batteries, like humans, are dynamic entities, susceptible to changes based on their environment and usage, with each exhibiting unique behaviours. This article explores the fundamentals of battery cell quality testing, the scalability of high-performance battery production, and strategies for future-proofing investments.

The fundamentals of battery cell quality testing

Validation engineers employ a diverse set of tests to ascertain various aspects of battery cell quality and performance, each with its own objectives with advantages and drawbacks. Let’s look at each one.

Visual inspection

Visual inspection is a basic yet subjective method used to identify physical defects or irregularities in the electrode coating, weld integrity, and cell structure. Artificial intelligence (AI) enabled automated optical inspection (AOI) offers speed, consistency, and precision, and can help streamline quality control. However, machine learning algorithms are trained to spot known defects or abnormalities, so certain limitations may exist.

Alternating current internal resistance

Alternating current internal resistance (ACIR) tests evaluate battery impedance under alternating current flows. The current is applied to the cell, and the voltage reaction is measured at typically 1kHz. The results are used to characterise the AC dynamic of the cell and detect any critical defects, offering insights into electrochemical processes, ageing effects, and internal resistance variations. However, this test is quite time-consuming and requires specialised equipment.

Electrochemical impedance spectroscopy

Electrochemical impedance spectroscopy (EIS) testing is a more advanced method, applying stimuli at various frequencies, typically between 0.1Hz to 10kHz, to capture defects not discernible with ACIR tests. This method enhances diagnostic capabilities, providing deeper insights into battery behaviour and identifying issues like premature ageing.

Direct current internal resistance

Compared to the more comprehensive ACIR and EIS tests, direct current internal resistance (DCIR) tests are a quick and straightforward way to gauge the internal condition of the cell and its functionality. High-intensity current pulses are injected into the battery to measure the ohmic response of the cell at different states of charge during charging and discharging.

Open circuit voltage

Open circuit voltage (OCV) tests measure the cell’s voltage when there is no applied load and no current flow outside the battery. This easy, non-invasive test shows correct cell activation and characterises how it degrades over time. Although this test only offers a limited understanding of the cell’s internal state, an excessively high or low OCV suggests a potential quality issue. These tests are frequently used to rate a battery’s performance and assess its health by estimating the leakage current of a cell throughout its production, pack assembly, and lifetime. For instance, OCV tests are performed during pack assembly to match and sort cells.

Leakage

While periodic OCV tests are commonly used to detect leakage when a cell is left to age, leakage tests are employed for early detection of leaks, cell damage or deterioration. Leakage tests are also used to assess the quality of the cell and battery packs.

One way to stabilise a voltage is to apply extra current to a cell. The internal leakage current is estimated by the additional current needed to regulate the voltage. However, this method takes a long time and yields inconsistent outcomes.

Another approach that is currently being researched is comparable to the EIS test. The cell is scanned at various states of charge using different current profiles, after which the response is assessed. This method is still in its infancy but shows promise by providing more consistent outcomes.

Scaling up battery production

As the demand for electric vehicles surges, battery cell quality becomes paramount for scaling production. By carrying out the appropriate tests as early as possible during production, problems are found before investing in expensive raw materials for a potentially defective product. But, due to increasing volumes, long test cycles, and the large footprint of the line, battery cell testing is adding further complexity to scaling up production.

An integrated test solution incorporating hardware, software, and automation allows battery manufacturers to analyse trends, identify critical testing steps, streamline workflows, and address production bottlenecks. Investing in automation not only boosts throughput but also reduces rework, scrap, and raw material costs.

Future-proofing battery test strategy

Staying abreast of market demands while fostering growth and innovation requires continuous evaluation of test strategies. Hyper-automation, artificial intelligence, and machine learning play pivotal roles in long-term test strategies, enhancing accuracy and efficiency, and delivering quantifiable business results to attract investment.

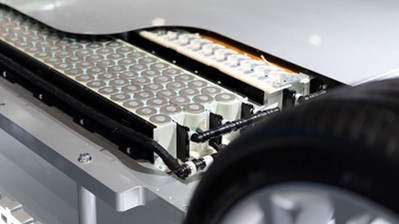

Cross-section of a battery pack in an electric vehicle

Handling data

Manual analysis and inconsistent data storage practices are common outcomes of fragmented systems. This may eventually hinder the capacity to innovate, and efficiently carry out root cause analysis and solve issues.

High-speed connectivity and the ability to gather enormous volumes of data and perform advanced analytics address fragmentation problems. This approach uses statistical, machine learning, and operational research techniques to analyse massive data sets from cell to pack level, facilitating data-driven decisions, defect prevention, and performance improvement.

Driving standardisation

Having tight controls helps reduce noise in test results and improves defect detection. Standardisation of testing hardware, software, and processes is crucial to ensure consistency and comparability of results across different batches, products, or suppliers. Standardisation is also imperative for meeting regulatory requirements and audits.

Modernising testing approaches is vital to delivering higher-performance batteries in the competitive and evolving battery market. A well-structured battery cell quality test strategy can turn testing into a strategic advantage, differentiating companies in this rapidly evolving landscape.

Authors:

Mike Patterson, Principal Applications Engineer, Automotive

Davide Cotterle, Principal Applications Engineer, Automotive

Manuel Hofmann, Chief Marketing Manager, Automotive