New air sensor to make chemical plants safer

Chemical plants will become safer places to work with a reduced risk of injury, chronic respiratory ailments or even death, thanks to a new air sensor being developed to detect toxic and explosive solvents using photonics.

Scientists from the University of Navarra in Pamplona, Spain have teamed up with the EU photonics innovation hub, ACTPHAST 4R to develop a demonstrator for their breakthrough optical sensing technology that detects lethal chemicals that are both dangerous to inhale and highly explosive.

No technology currently exists to perform a real-time, automatic check in fuel tanks for Volatile Organic Compounds (VOCs) - chemicals that evaporate quickly at room temperature. Technologies that are generally used to monitor these chemicals currently use electronic sensors that need to be heated past 150°.

Emptying giant tanks filled with alcohols, ketones, aldehydes, chloroform, and dichloromethane, chemical plant staff have to ensure no traces of vapour or liquid remain.

Having to climb inside these giant tanks, workers are under constant threat of causing an explosion from friction or static electricity.

With the help of ACTPHAST 4R - the EU innovation hub specialising in supporting researchers working in academia throughout Europe to advance their breakthrough scientific concepts into industrially-relevant demonstrators using photonics - the research team from the University of Navarra has managed to successfully develop a demonstrator for their innovative solution to safely identify these toxic and explosive solvents in industrial settings.

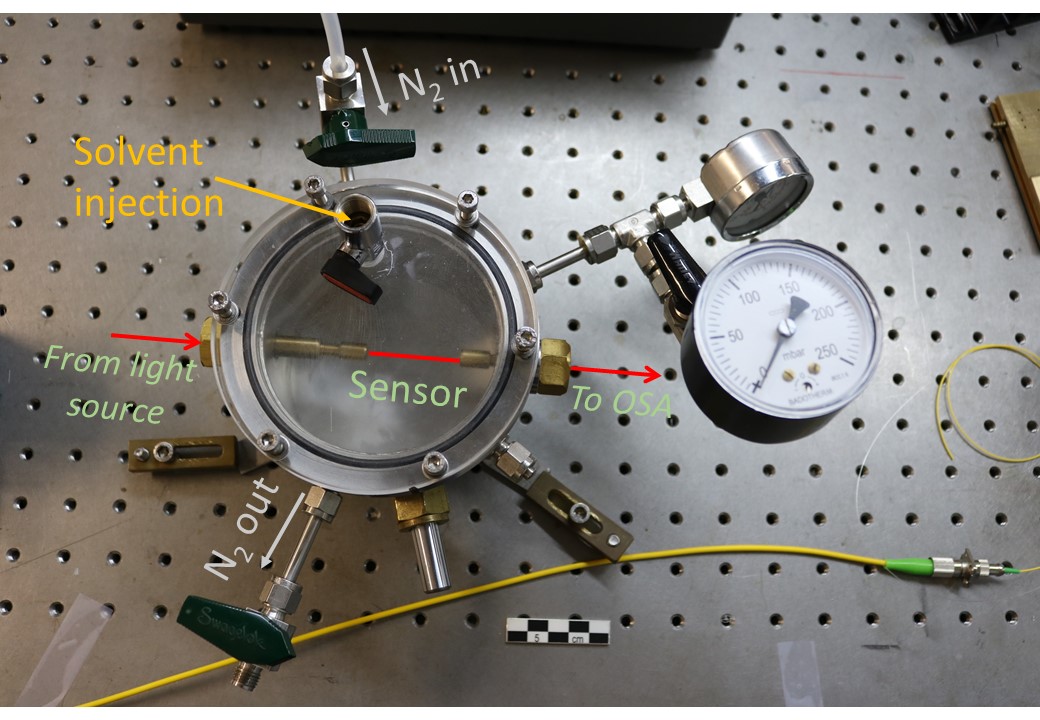

This new detector uses optical fibres - the cables that carry vast amounts of data via the Internet - to monitor air quality, with no electrical or flammable components as part of the device. The optical fibre sensing solution is designed to be ideal for dangerous places where electricity is forbidden and could soon create safer working conditions for chemical plant staff who handle highly toxic and explosive chemicals.

The number of worldwide deaths from chemical-related incidents is surprisingly common, with 681 fatalities reported in global media in 2017 alone. High profile chemical plant explosions in the past year include the Port Neches Chemical Plant explosion, Texas (November 2019), the La Canonja explosion (January 2020), and the surfactant unit explosion of Tarapur, Maharashtra (April 2020), to name a few.

Demonstrator

With a demonstrator ready, the researchers say it will require further testing before being commercially available.

The lead researcher on the project, Dr César Elosúa Aguado from the Electrical, Electronic Engineering and Communications Department Public at the University of Navarra, said: “An air sensor using optical fibres for the purpose of VOC detection is a major scientific breakthrough concept. It is currently in its pre-prototype, ‘demonstrator’ phase but has the potential to be further developed for industrial application.

“The innovation support we have received from ACTPHAST 4R has been crucial to bridging the gap between the ‘valley of death’ in innovation and accelerated TRL advancement.

“Research teams like ours do not have easy access to the relevant cutting-edge photonics expertise and technologies within their universities or even our regions. The innovation hub ACTPHAST 4R has been essential in developing the cross-border connections to the expertise that we needed to go further.”

If the demonstrator is successful, the researchers will look at commercialisation options such as licensing or a spin-out company from the university, to take it to the next stage of a working prototype and eventually a full commercial product.

Light versus Electricity

Today’s electronic sensors use metallic oxides that are capable of sensing toxic chemicals but are not safe in the shipping of chemical solvents. When exposed to VOCs, semiconductor metallic oxides show a change in electric resistivity and have been used to develop electronic sensors for many years but can be unsafe and slow to use in dangerous environments.

Dr Elosúa Aguado said: “We want to create the safest chemical plants ever made, putting workers lives and wellbeing first. This technology allows instantaneous, real time monitoring and not having to wait days for samples to come back from a laboratory.”

Combining several different platforms never previously considered for automated gas detection, the new sensor looks at the interaction between the cladding modes and the sensitive coating - producing a new signal when the toxic substance is present.

“We still use metallic oxides but our system looks at the refractive index of the sensing material, rather than changes in electrical conductivity.

“The sensor surface is coated with zinc oxide oxides as a sensing material that reacts when the harmful material is present.”

“Cladding modes are a part of the optical signal that is 'forced' to travel by a Bragg reflector, not through the core but around the cladding, enabling an interaction with the surrounding media,” Dr Elosúa Aguado said.

The sensor is therefore specifically ‘tuned’ to a toxic substance, meaning the only molecules that are captured along the sensor are those dangerous gasses. The reactivity to the gas (known as ‘selectivity’) will depend on VOC molecular properties, such as polarity.

“The reaction mechanism between the metallic oxide and the VOC is a reversible redox chemical reaction. The selectivity of these materials is low, so they react to a wide range of solvents with different sensitivities. Therefore, sensors with different responses combine to form a specific pattern for each VOC.”

“The sensor response will be used to train an artificial intelligence system capable of identifying the different VOC samples,” said Dr Elosúa Aguado.

ACTPHAST for Researchers

To bring their idea to life, the Spanish research team needed support from top photonics experts with access to specialist technology platforms and materials. ACTPHAST 4R is an EU photonics innovation hub specialising in the deployment of photonics technologies that gives European researchers the chance to turn their breakthrough scientific concepts into industrially-relevant demonstrators through a 'one-stop-shop'.

Dr Elosúa Aguado said: “ACTPHAST 4R provided rapid access to the technical specialists and cutting-edge technologies in photonics that we needed to develop the sensor and helped to substantially fund the innovation work.

ACTPHAST 4R provided us with open access to expert coaching in the accelerated development and deployment of photonics, as well as hands-on training in the facilities of one of Europe’s top competence centres for our application and complementary business coaching on our future plans towards commercialisation of our technology.

The application process via the ACTPHAST 4R website was quick and easy too. We would recommend working with ACTPHAST 4R to any researchers looking to innovate with photonics.”

ACTPHAST 4R operates a continuous open call for researchers who wish to apply for innovation support. Applications can be made online via the ACTPHAST 4R website here.