Board-mounted sensors meet pressure challenges

Today’s liquid-compatible, board-mounted sensors are meeting the challenges involved with pressure sensing in high-humidity environments. By Bryan Hovey, Product Manager, Pressure and Thermal, Honeywell Sensing and Control.

Designers face a big challenge when selecting pressure sensors for medical and industrial applications that must withstand condensing humidity or that must directly measure the pressure of liquids. Often, they have to deal with tradeoffs in functionality, packaging, and cost. In addition, there are few sensing options for devices that require liquid compatibility outside of large, heavy media-isolated pressure transducers. These sensing devices were once the only choice for designers before the introduction of liquid-compatible, board-mounted sensors.

When used with applications with low or medium pressure requirements - such as gas or liquid chromatography, chemistry analysers, ventilators, and blood analysis and diagnostic equipment - pressure sensors may have to interface directly with liquid media or deal with humid environments while providing highly accurate pressure measurements for a variety of media including expired air, reagents, samples, and cleaning fluids. In applications with a pressure range of less than 150psi and size constraints, a board-mounted pressure sensor is often the preferred solution, offering the right balance of functionality, package size, reliability and cost.

For the most accurate pressure reading, sensors should be positioned in close proximity to the media being measured. However, not all pressure sensors are liquid compatible, creating a key challenge for medical and industrial device designers. In most board mount pressure sensors, wire bonds, ASICs and other electrical components are directly exposed to the media. Liquids can quickly cause failure of the sensor or shifts in its performance. In many cases, to gain the advantages of using a board mount sensor, the designer must incorporate a bypass or a filter to address humidity issues, or rethink the positioning of components, particularly the tubing, in the system to keep any fluids from contacting the sensor. This can result in additional design time and cost, and may affect the performance of the pressure measurement.

Protection

Today, sensor manufacturers are developing board-mounted products that are protected against liquid media and high humidity environments for medical and industrial applications that require low to medium pressure measurements. These sensors also help simplify designs by eliminating the need for additional protection features or product redesigns so the fluids won’t contact with the sensor.

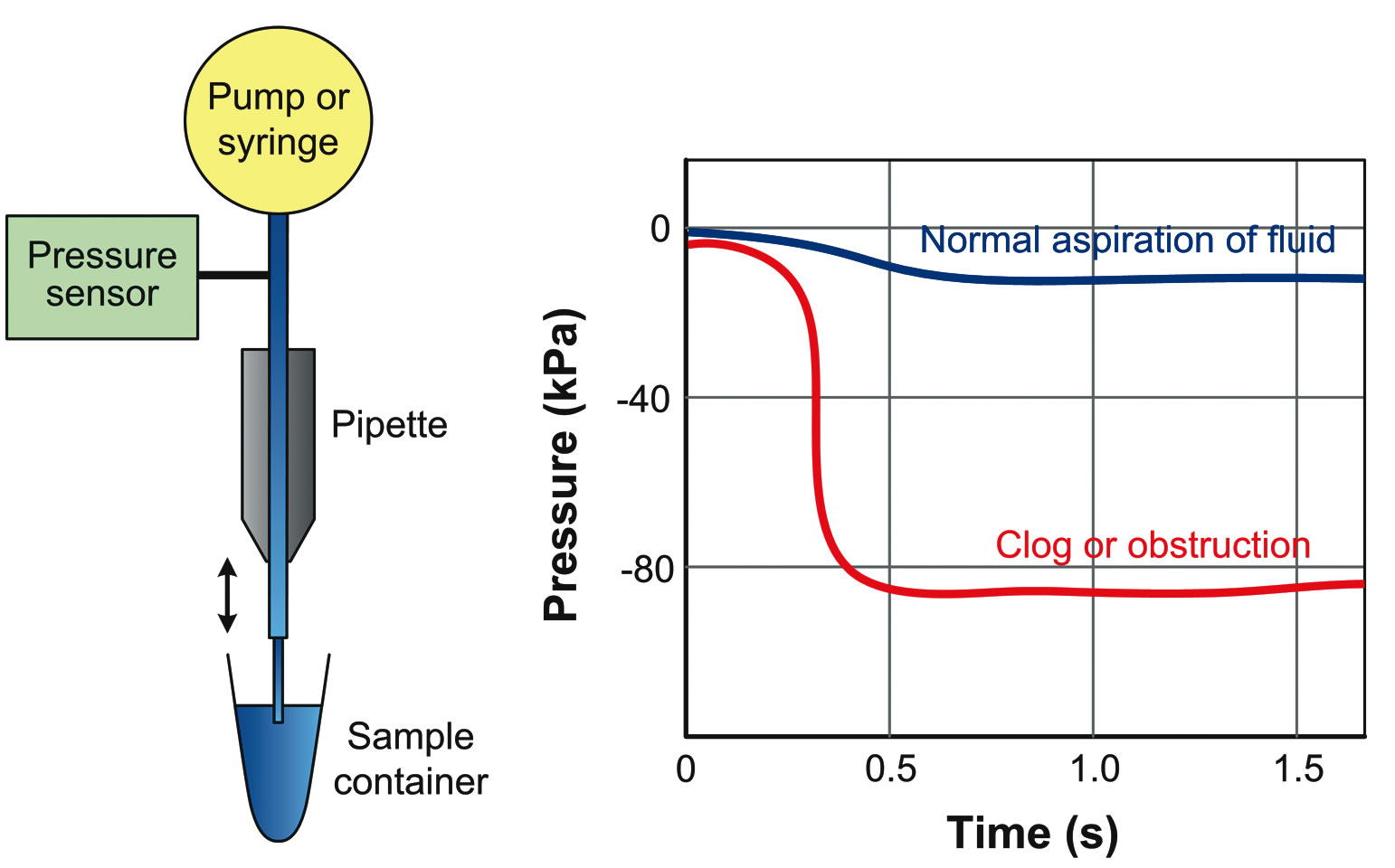

Figure 1 - Some systems compare pressure profiles to a ‘known good’ profile

As an example, a board-mounted, liquid media-compatible pressure sensor is a good choice for a chemistry analyser because it requires the precise measurement of fluid passing through the system. In addition to providing accuracy and repeatability at low pressures in chemistry analyser applications, pressure sensors need to withstand higher pressures during flushing and cleaning.

Typically, in this application, a pipette draws the sample fluid and deposits it into another vial or container for mixing or analysis. Pressure sensors are used to ensure that the right amount of fluid is being measured while the sample is being drawn, and they can also be used to detect obstructions or misplacement of the pipette in the sample vial. All of this is done while in direct contact with the liquid media being measured.

Examples of such sensors include the Honeywell Sensing and Control’s 24PC/26PC board-mounted pressure sensors, which can detect such small changes in pressure. They can also be used to provide precise and repeatable measurement of a specific amount of fluid passing through the system, which is a key requirement for analytical equipment. Most significantly, the sensors are unique in that they offer liquid media compatibility on both pressure ports.

Honeywell’s TruStability pressure sensors provide a wide range of configuration options to speed up design and development time. A philosophy used in development of the sensor was that the sensor should be adaptable to the requirements of the end product rather than require the designer to adapt the design to the available sensor configurations.

TruStability can also be used in applications such as ventilators where the media will routinely or even continuously contain liquid. In a Ventilator, the sensor measures the pressure of the air flowing to and from the patient. To ensure that the air and oxygen pressure does not exceed the level set by the medical professional, the sensor needs to provide high stability and accuracy. The tight accuracy of HSC/SSC pressure sensors allows them to be used in a ventilator, detecting pressure at ranges down to 250Pa (an inch of water column). These sensors offer I2C or SPI digital outputs, allowing them to be directly interfaced to microprocessors or microcontrollers.

The TruStability sensors offer a liquid media option that allows them to withstand direct liquid media contact or condensing humidity. For example, this option should be a key consideration when the sensors are placed close to the patient, particularly within the expiratory portion of the ventilator. This is where the sensor is subjected to high humidity air from the patient during coughing and breathing.

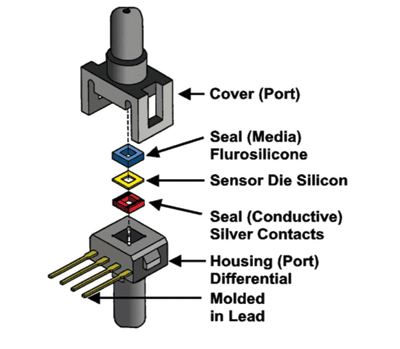

Figure 2 - Pressure sensors can offer several seal options to meet the requirements for a wide range of liquid media and humid environments

The 24PC/26PC and HSC/SSC pressure sensors allow the designer of complex devices to position the pressure sensor as close as possible to fluids or humid gases to achieve the most accurate pressure reading. These sensors can handle a wide range of noncorrosive, nonionic liquids or gases. They provide design flexibility through options for specifications such as pressure range, package styles and digital/analog outputs. The 24PC/26PC pressure sensors offer several seal options to meet requirements in a wide range of liquid media and humid environments.

Because many applications have the potential to be in contact with fluids and gases, designers should always consider pressure sensors with liquid media compatibility to simplify their designs. Designers should understand what types of fluids may be in contact with the pressure sensor to ensure that it is compatible with those fluids.

Designers also should evaluate pressure sensors that are fully compensated, amplified, and calibrated for easier implementation. These sensors can eliminate components from the printed-circuit board related to signal conditioning. Advantages range from space savings and higher reliability to lower costs and faster implementation.

Selecting the right pressure sensor depends on the application’s requirements; a low-cost, unamplified, uncompensated pressure sensor with liquid media compatibility may be all that’s required for an alarm circuit. Pressure sensors should be easy to integrate into a design by offering flexible configurations through options for port styles, packaging, output types (analog and digital) and other features.