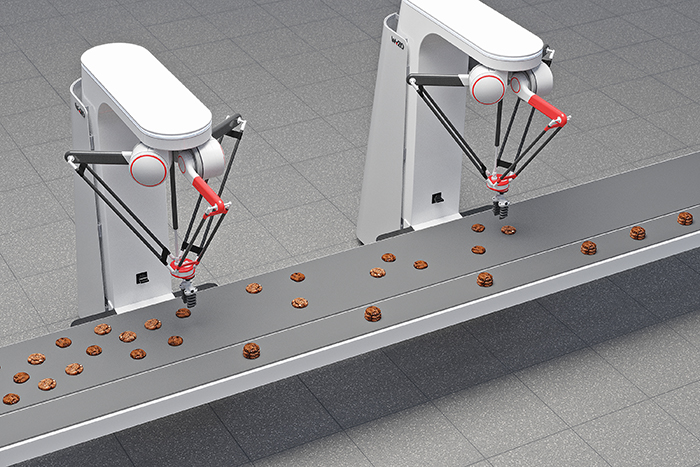

The world’s first direct-drive sidebot

Wyzo, the world’s first direct-drive pick-and-place sidebot, will be showcased to the US market for the first time at PACK EXPO Las Vegas on 27th-29th September. From artisan companies taking their first steps into automation to established large-scale manufacturers, visitors to booth 6027 can experience first-hand how Wyzo can work safely side-by-side with humans with zero protective barriers or performance compromises.

Well suited for lightweight applications with a payload up to 1.1lbs, Wyzo is suitable for the food and beverage, consumer goods, pharmaceutical, cosmetics, automotive, electrical and electronics sectors. Wyzo is the result of 30 years of Delta robot experience, coupled with a vision to deliver a safe and highly efficient sidebot that can add considerable value to operations of all sizes.

Its pioneering direct-drive technology means there is no gearbox – reducing maintenance costs to near zero – while its compact design and high-speed operation of up to 90 cycles per minute make it the suitable for day-to-day tasks on the production floor. Wyzo’s advanced safety system is enabled through its state-of-the-art sensor technology, which constantly monitors its surroundings for the presence of human activity, while optional vision systems compatible with a variety of established hardware platforms ensure ease of integration into any production environment.

Frank Souyris, Chief Executive Officer at Wyzo, commented: “PACK EXPO Las Vegas is the first step for Wyzo into the US market, and we could not be more positive about the impact it will make to manufacturers of all sizes. As the labor market in the US continues to be challenging, the move towards greater levels of automation is accelerating. However, until now, pick-and-place robots have been accessible only to companies with the CapEx required to invest in highly automated solutions – often shielded from operatives by protective doors. With Wyzo, we have created a sidebot that is far more inclusive, meaning companies both large and small will be able to benefit from its compact size, flexibility and all-round versatility.”

With labour availability an ongoing challenge, ease-of-use has also become ever more important. As a result, Wyzo’s human machine interface (HMI) has been designed for intuitive use by operators with no prior training in automated solutions, while its mobile terminal is as easy to operate as a smartphone and requires neither script nor programming to get it up and running. Its advanced software has been developed with pure flexibility in mind, meaning Wyzo can be moved quickly and efficiently between multiple workstations with only a single cable connection to remove and reattach.

Frank Souyris continued: “To be able to present Wyzo to the US market in person is very exciting as, to a certain extent, the benefits Wyzo can deliver need to be seen to be believed. Its scope in terms of meeting production needs has broken through every barrier of expectation, while its flexibility is perfectly suited to the ever-changing demands consumers are placing on manufacturers. No stone has been left unturned. For example, at less than 5.5 sq ft and just under six feet in height, Wyzo fits through standard doors and elevators, offering unprecedented flexibility with a small footprint. It can easily be moved from one workstation to another, eliminating bottlenecks and enabling fast ROI, and for manufacturers switching between products it is highly compatible with all regular grippers on the market with changeover speeds of less than nine seconds.”

Two Wyzo sidebots will be on display at booth 6027, allowing visitors to experience its capabilities first-hand – whether it is to witness its incredible speed and compact size, interact with the user interface or even to stop it in its tracks by putting a hand in its way.