Helmet smartfoam signals potential concussions in real time

Most football fans have seen players get hit so hard they can barely walk back to the sideline. All too often in years past, those players were back on the field just a few plays later, despite suffering what appeared to be a head injury. While football-related concussions have been top of mind in recent years, people have struggled to create technology to accurately measure them in real time.

Enter BYU mechanical engineering Ph.D. student, Jake Merrell, and a team of researchers across three BYU departments. Merrell and others have developed and tested a nano composite smartfoam that can be placed inside a football helmet (and pads) to more accurately test the impact and power of hits.

The foam measures the impact of a hit via electrical signals. The data is collected in real time and sent wirelessly to the tablet or device of a coach or trainer on the sidelines. A coach can know within seconds how hard a player has been hit and whether or not they should be concerned about a concussion.

“The standard measurement systems on the market today directly measure the acceleration, but just measuring the acceleration is not enough and can even be erroneous,” Merrell said. “Our XOnano smartfoam sensors measure much more than just acceleration, which we see as a vital key to better diagnose head injuries.”

The foam, which replaces the standard helmet foam, measures a composite of acceleration, impact energy and impact velocity to determine impact severity and location of impact, all with 90% accuracy, according to research published by Merrell in the Annals of Biomedical Engineering.

To date, no one — not even the NFL — has been able to successfully measure the impact energy and velocity of a collision, which are two data points necessary to accurately measure whether a player is at risk of a concussion or not.

Here’s how the BYU smartfoam works: When the foam is compressed, nickel nano-particles rub against the foam, creating static electric charge, similar to when you rub a balloon against your hair.

That charge is then collected through a conductive electrode in the foam, measured by a microcomputer and transmitted to a computer or smart device. A hard hit spikes the voltage, while small impacts result in a reduced spike in voltage.

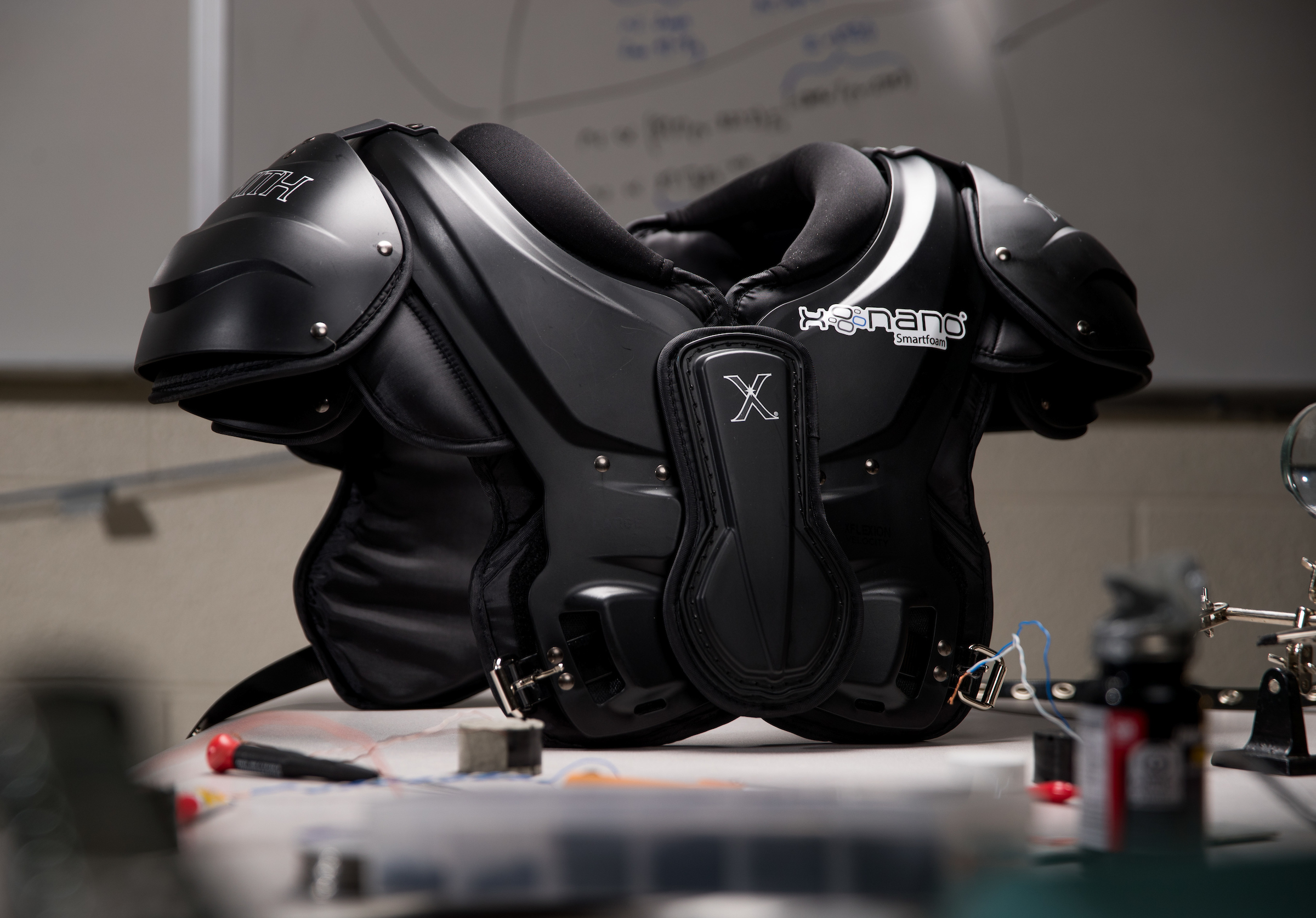

Merrell is excited for the future of his smart foam technology as companies incorporate it into their products. Merrell and Xenith created shoulder pads with the impact sensing technology, and a company producing taekwondo vests has also started using the smartfoam to score fights and train athletes.

Merrell is currently working with the U.S. Army on an insole to understand biomechanical forces and devise strategies to prevent musculo-skeletal injuries.

“The success of smartfoam epitomises the inspiring learning that happens at BYU,” said mechanical engineering professor David Fullwood. “It was discovered by a graduate student, and perfected by a small army of undergraduates. Not only did we discover exciting science, but we also uncovered the scientists in the entire team of students.”

Merrell worked with researchers in the mechanical engineering, exercise science and statistics departments at BYU on the nano composite foam. Fullwood, fellow mechanical engineering professor Anton Bowden, exercise science professor Matthew Seeley and statistics professor William Christensen were all coauthors on the study.