Testing time is money: The impact of equipment issues

Testing is a crucial element in the development cycle of any product, solution or service. No matter what sector a business operates in, it will be subject to specific frameworks, standards and regulations governing testing to assure that its products operate effectively and safely. But the demands placed on R&D engineers have proliferated in recent years, as the landscape becomes more complex with increased time pressures to bring new products and services to market. Ted Burns, Global Director of KeysightCare at Keysight explains more.

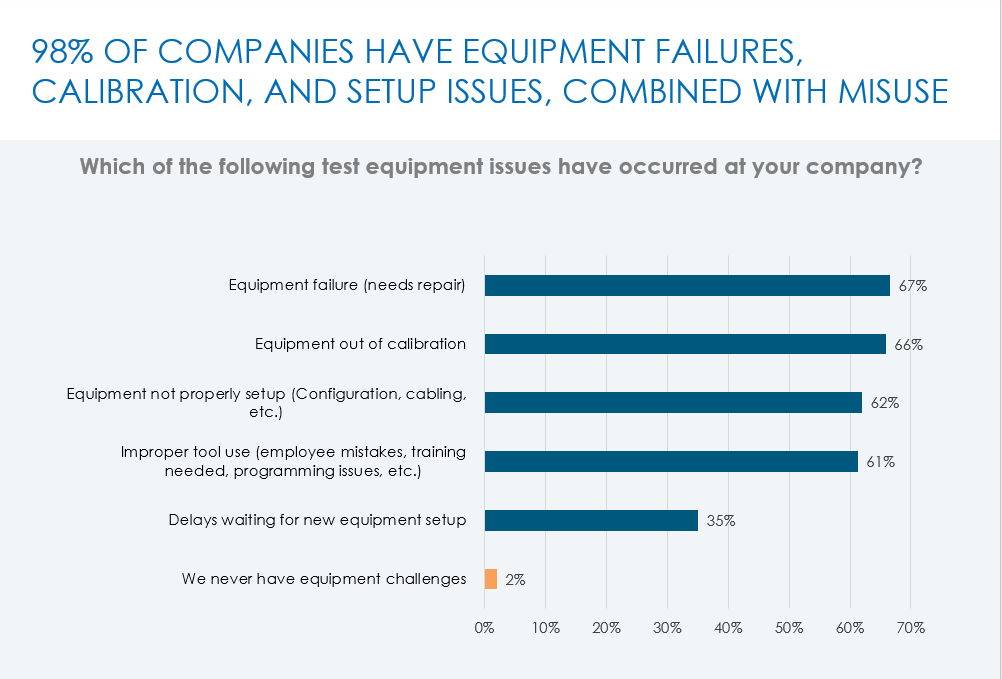

There are growing incidences of workflow issues related to use of test equipment; whether because equipment has been misconfigured, test engineers lack the necessary training or knowledge, or environmental interoperability or equipment failures cannot be debugged and resolved quickly enough. This materially adds to the intensity of development cycles.

The survey, conducted by Dimensional Research, consisted of 305 R&D engineers from a range of global organisations, including those in the technology and telecoms sectors. The results were clear - more than 90% of companies have experienced a revenue loss because of preventable delays related to test and measurement equipment.

For more than half - 53% of companies - that revenue loss amounts to more than US $100,000 (£75,000) of waste per day waiting to resolve technical support issues. Loss of time results in loss of money. So how did this situation arise, and what can be done about it?

Test cases increase by orders of magnitude

To remain competitive, companies must eliminate obstacles that cause delays. Design complexity, frequent design changes and unfamiliar new technologies with rapidly developing standards can force engineers to troubleshoot technical issues on the fly. Product or service development schedules do not account for time required to troubleshoot and debug such issues. To maintain aggressive schedules, they must do so without the right resources, training or expertise.

In the past, engineers would develop a deep familiarity with test equipment design and test standards. Today, they simply do not have the time to research how their test equipment works, how to optimise a configuration, or how to troubleshoot a complex setup to achieve the results specified in specs and industry standards. And with constant pressure to shorten new product development life cycles, market-leading companies cannot afford to wait days to access technical support experts for issue resolution.

As a practical example - in the past, R&D engineers would routinely download technical manuals to learn the inner workings of a product. They had an intimate understanding of the operation, test configuration and use cases.

Today, test matrices have spiralled vastly increasing test cases both in number and complexity. It is no longer feasible to master those cases while meeting customer expectations and time-to-market goals. R&D engineers rely on automation and sophisticated software to achieve speed. But if a test case fails, troubleshooting can be difficult and time-consuming.

Escalating business issues

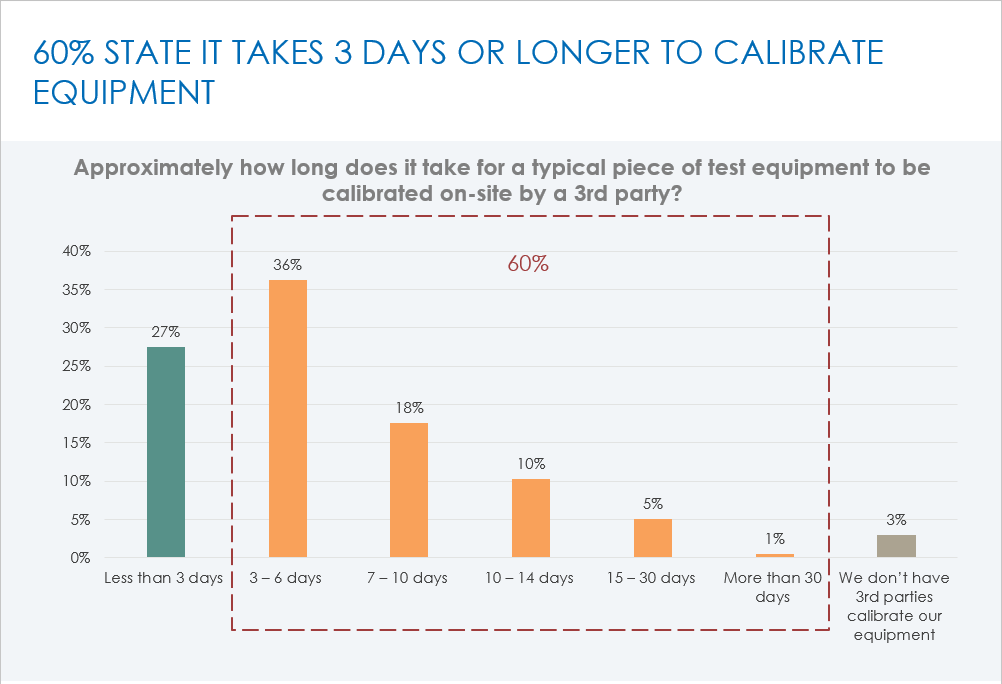

Keysight’s 3rd party commissioned survey found 91% of respondents said they experience business-impacting issues related to calibration, technical problem resolution or equipment performance. In addition, 46% reported their business suffers within the first day with test equipment not functioning to expectations. Further, 72% said calibration issues affect their business within three days, yet and average of 65% said that the time it takes to calibrate and repair equipment is not fast enough, or predictable, lacking the needed Service Level Agreements (SLAs) to help mitigate schedule slips.

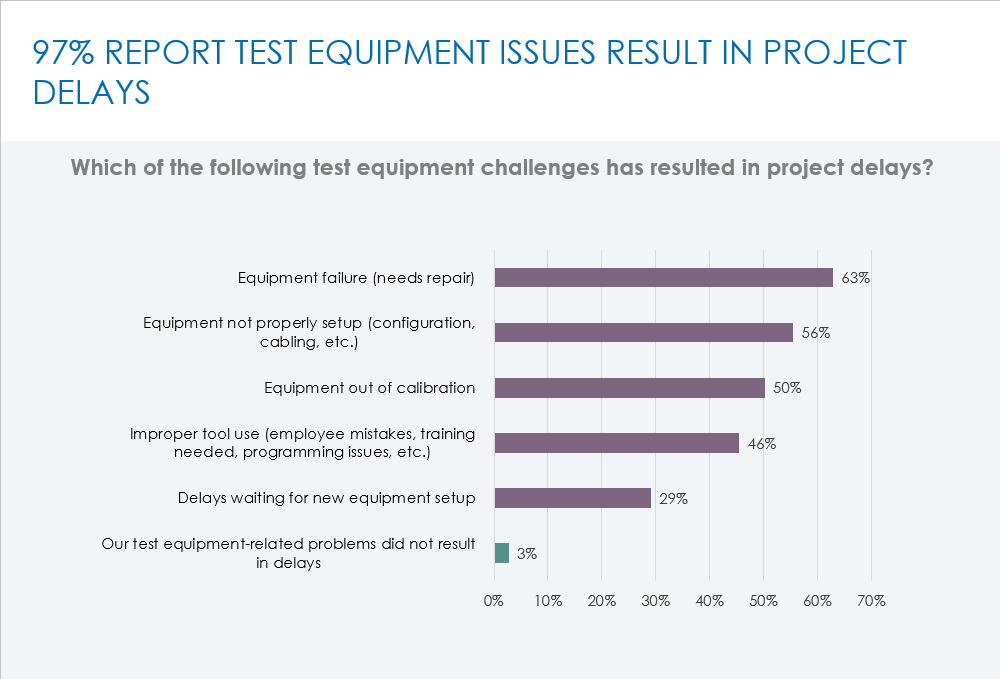

All in all, 97% of respondents had experienced problems with test equipment which resulted in project delays. This included 63% of respondents who said they had experienced test equipment failure, which then required repair. 56% said they had experienced problems due to test equipment being improperly set up - problems with configuration, cabling and so on. 50% had experienced equipment being out of calibration, and 46% had experienced problems with improper tool use - employees making mistakes, lack of training, programming issues and so on. 29% had experienced delays waiting for new test equipment to be set up.

Impact on the bottom line

All these problems can have critical business impacts. If the R&D engineering team cannot work for a single day because of problems with test and measurement equipment, the cost can be severe. 53% of survey respondents said that the cost of this was $100,000 a day or more - and 5% said it was more than $1m.

In addition, 91% of respondents explained that such issues had a tangible and material business impacts, from reducing product yield (cited by 53%), to products being rejected by buyers (47%), to increased product returns (45%) and even product recall (28%). Such occurrences are costly. And those costs can linger for multiple quarters as firms struggle to regain their customer’s confidence as a quality supplier.

Changing expectations and demands

In this complex environment, it is not surprising that 60% of reported problems relate to incorrect test equipment setup or improper use. These factors alone suggest that as product designs and test solutions increase in complexity, access to technical support expert resources and information grows more important. When problems arise, companies need fast, reliable guidance to troubleshoot and resolve issues. Having the right technical support can reduce time to resolution when troubleshooting and diagnosing advanced measurement techniques.

Note how often test professionals require assistance: 95% said they need help every month, and 59% said they experience six or more technical support issues each month. Ninety-four percent of electronic test professionals said they need committed, fast-response technical support.

What is even more apparent is that expectations and demands upon technical support have dramatically changed. Nearly half the professionals surveyed said existing technical support models do not meet their expectations and business needs. They said technical support models need to be highly knowledgeable, immediately accessible with faster, committed response times 68% thought they could save multiple days each year using a priority support model.

Making a material difference

Modern testing and development require a modern technical support approach, tailored to meet the needs of agile, connected design and test. Each generation of technology increases this complexity. Test and measurement companies must respond and resolve technical support issues faster to help their customers stay ahead of test standards, test methodology and equipment maintenance.

Overall, priority access to test experts with committed response times and proactive notifications, calibration services and repair facilities with committed turnaround times and a digital experience, can make a material difference, whether engineers are designing or manufacturing a product. The right support can enable a team to deliver a quality product on schedule and help avoid the design or production issues that result in costly delays.