Wireless torque sensors ensure airliners’ safety

The aerospace sector is renowned for its safety standards and a whole industry has grown up to provide equipment and services for testing aircraft and their subsystems. Airliners are subject to tremendous loads as they land and take off, from the touchdown of the undercarriage, to the back-thrust of the jet engines as they slow the aircraft on the runway and the wind pressure on the flaps and flight control surfaces when they are lowered to provide air-braking.

Furthermore, these loads can increase exponentially in difficult or emergency situations, so it is essential that the relevant parts are regularly tested and recertified as fit for purpose.

SGN Electrical in Sittingbourne, Kent has recently built two test rigs, one for testing the landing gear, the other for the flaps on the tail plane, that are helping ensure transoceanic-scale airliners capable of carrying hundreds of passengers can land safely and reliably every flight.

SGN is well-known for its electrical contracting services to most industries in the south east, including at the region’s main airports where ‘right first time and right on time’ is the expected standard no matter how challenging the work. Its engineers have a wealth of experience in inspection and testing, from small installations to hazardous areas, aerospace and other specialist fields. As well as electrical skills it is equally well versed in mechanical engineering, so was a natural choice to build the test rigs.

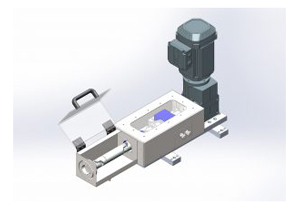

One rig tests the ballscrews used to raise and lower the tail plane flaps. Rather than just a function test, the rig simulates the high speed air flow over the aircraft while it is in flight, using a hydraulic actuator to apply a measured but varying load to the ballscrew.

The second rig is for testing the landing gear by simulating the loads on the main lead screw as the wheels are lowered and touch down. This includes the extra loads that are likely to be experienced in bad weather and the sudden shock loads that might occur in an emergency landing.

Both test rigs use a TorqSense transducer made by Sensor Technology in Banbury as their main element. TorqSense is much-favoured by test rig builders as it is a non-contact technology that uses reflected radio waves to measure the torque in a rotating shaft.

“There is no need to spend time setting up fiddly slip rings every time you use the rig,” explained SGN’s Scott Nicholson. “You just point the sensing head at the test piece and real time data is collected. We run this through a standard Sensor Technology controller and the results are both displayed on a digital screen and stored for later analysis.”

In use, two piezo electric combs are glued to the test shaft at right angles to one another. Their role is to reflect back radio waves aimed at the shaft by the TorqSense, but as they distort in proportion to the torque in the shaft (one compressing, the other expanding), they in turn distort the reflected waves. The amount of wave distortion is proportional to the comb distortion, which reflects the deformation of the shaft and therefore the level of torque it is experiencing.

“Using TorqSense makes it easy to build a test rig,” said Nicholson. “But far more importantly it makes the tests much, much quicker and easier. Therefore more tests can be done in a given time, which means results can be checked, double-checked and checked again – which is pretty much the operating procedure required for aircraft safety.”