Taking control of temperature

High accuracy temperature sensors improve system performance and reliability. By Christoph Schwoerer, Design Section Leader, and Gerd Trampitsch, Design Engineer, Linear Technology.

The march toward increasingly dense computing power has amplified the challenges related to heat. In many systems, the capabilities of the cooling system are a significant limitation to overall performance. Standard cooling components, such as bulky heat sinks and power-hungry noisy fans (or expensive quiet ones) impose size limitations on tightly packed electronics. The only way to maximise performance, minimise cooling requirements and ensure the health of the electronics is with accurate, precise and comprehensive temperature monitoring throughout the system.

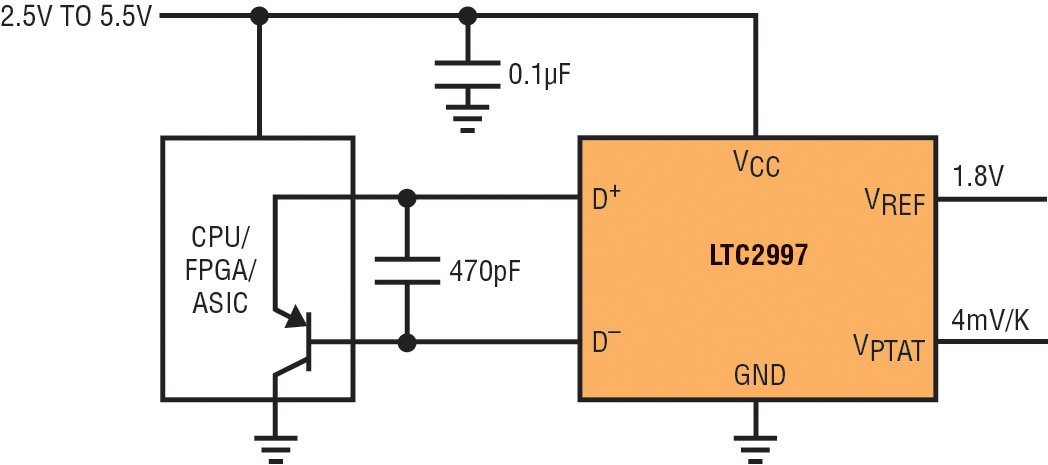

With this in mind, Linear Technology has developed a family of highly accurate temperature monitors that can be easily distributed throughout a system. The LTC2997, for example, is available in a 2x3mm 6-pin DFN package and can be used to measure the temperature of an FPGA or microprocessor as shown in Figure 1.

Figure 1 - Remote CPU temperature sensor

The device sends measurement currents to the temperature monitoring diode of the FPGA or microprocessor and generates a voltage proportional to the temperature of the diode on its VPTAT output. It also provides a 1.8V reference voltage at the VREF output, which can be used as a reference voltage for the onboard ADC in the FPGA or MPU. The measurement error in this configuration with external sensor element is guaranteed to ±1°C over the temperature range from 0 to 100°C and to ±1.5°C from -40°C to +125°C; typical temperature measurement error is far better.

Operating principles

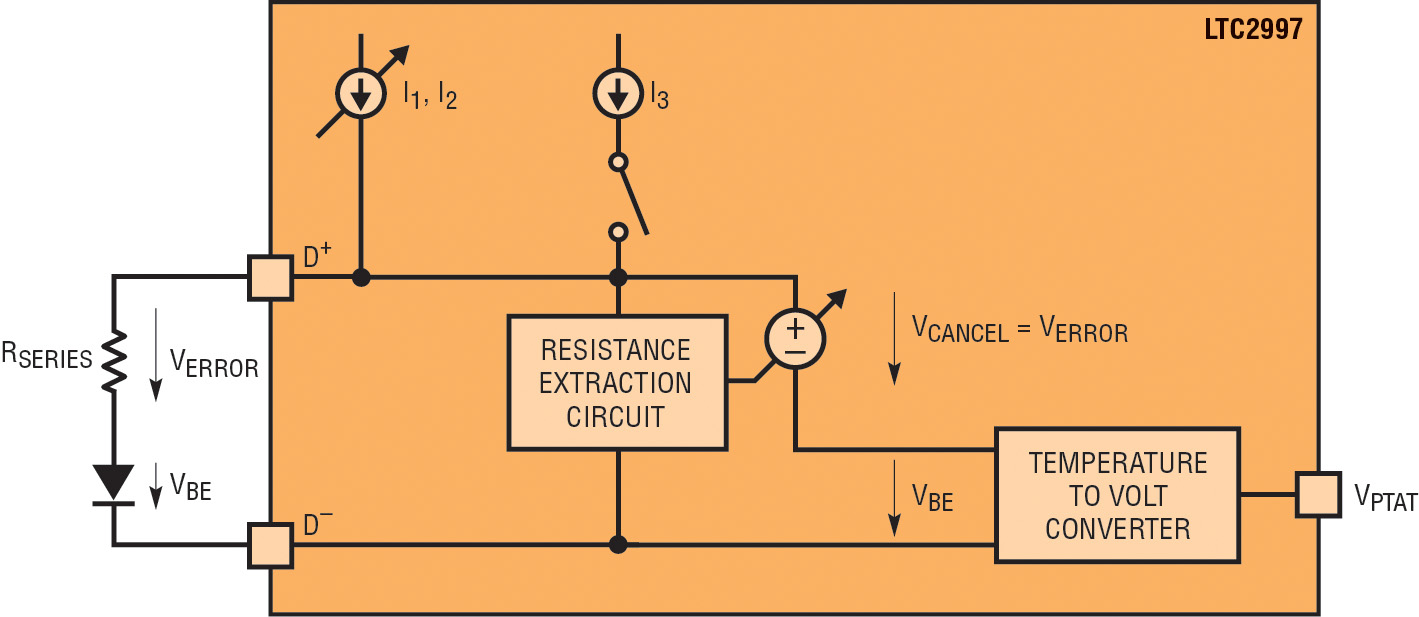

Accuracy is achieved by measuring the diode voltage at multiple test currents and using the measurements to remove any process-dependent errors and series resistance errors. The LTC2997 removes this error term from the sensor signal by subtracting a cancellation voltage (Figure 2). A resistance extraction circuit uses one additional measurement current to determine the series resistance in the measurement path. Once the correct value of the resistor is determined VCANCEL equals VERROR. Now the temperature to voltage converter’s input signal is free from errors due to series resistance and the sensor temperature can be determined.

Figure 2 - Series resistance cancellation, a simplified block diagram

Series resistance up to 1k typically causes less than 1°C of temperature error, which makes this part a suitable device to read out diode sensors that are several meters away from the temperature management system. Indeed, the maximum distance is limited more by the line capacitance than by the line resistance. Capacitances larger than 1nF start to impact the settling of the sensor voltage at the various sense currents and therefore introduce additional temperature reading errors. For example, a 10m long CAT 6 cable has about 500pF of capacitance.

Unlike many remote diode sensors, the LTC2997 accurately tracks fast changing temperatures due to its short update time (3.5ms) and its robust temperature measurement algorithm in the face of temperature variations, even during a measurement interval.

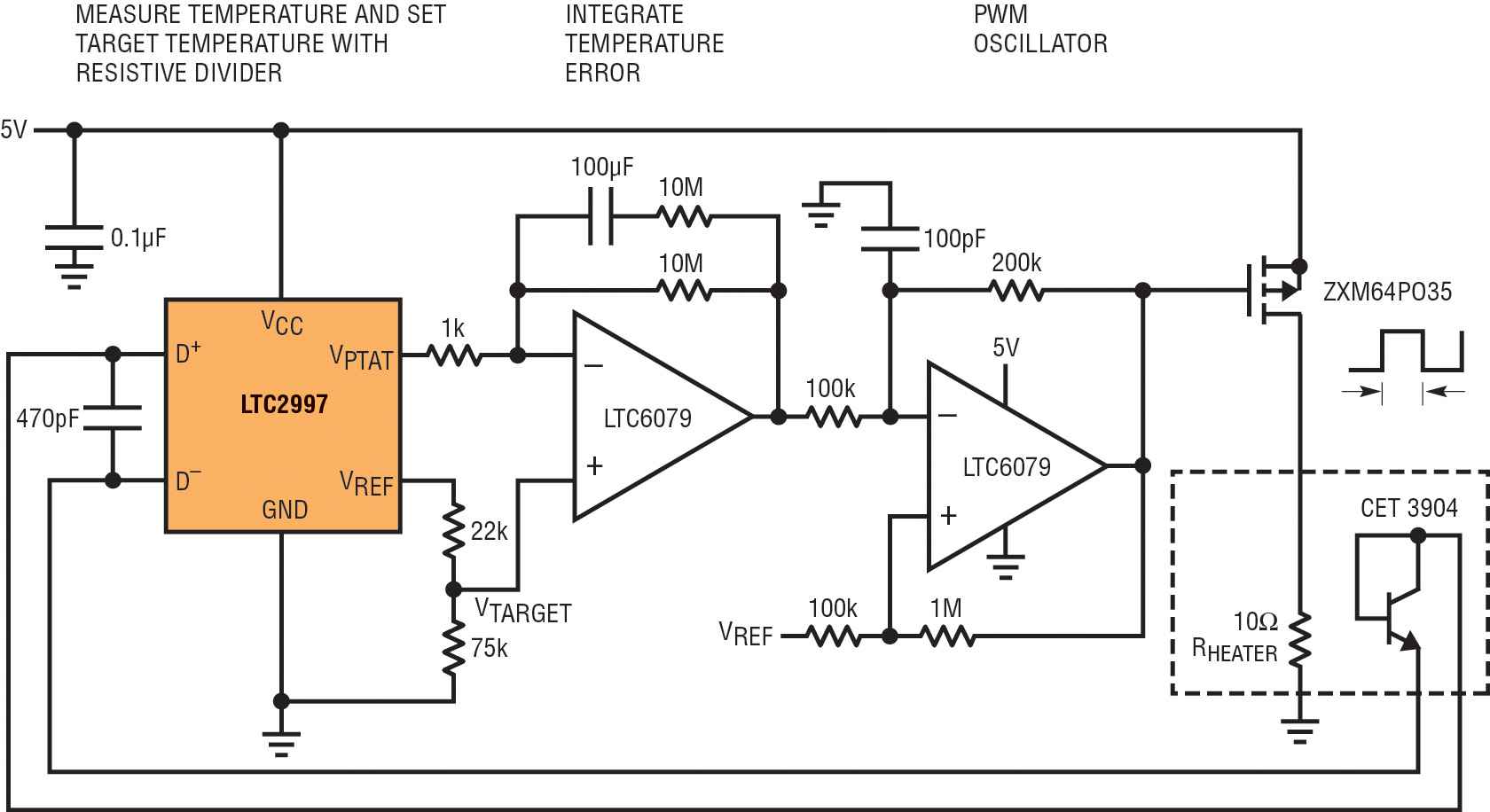

The device also has many advantages over its digital counterparts when applied in temperature regulation loops. Its fast response time and analogue output temperature eliminate much of the complexity required by digital systems. For example, Figure 3 shows the LTC2997 in a heater that regulates at 75°C. In this application, the reference voltage is used to generate - by means of a resistive divider - a target voltage of 1.392V.

Figure 3 - 75°C analogue PWM heater controller

The first micropower rail-to-rail amplifier integrates the difference between the VPTAT output and the target voltage. The integrated error signal is converted to a pulse width modulated signal by the PWM oscillator, which in turn drives the switch of the PMOS, controlling the current through the heating resistor.

The LTC2997 can also be used to build a Celsius thermometer, a Fahrenheit thermometer, a thermocouple thermometer with cold junction compensation or in countless other applications where accurate and fast temperature measurements are required.

Temperature monitor

The LTC2996 adds threshold inputs VTH and VTL to the LTC2997 and continuously compares VPTAT to these thresholds to detect OverTemperature (OT) or UnderTemperature (UT) conditions. The threshold input voltages can be set by resistive dividers from the built-in reference voltage. If the temperature of the remote diode increases above 70°C, the VPTAT voltage exceeds the high temperature threshold at VTH. The LTC2996 detects this OT condition and alerts the temperature control system by pulling the OT pin low. In the same way, a temperature falling below -20°C is communicated via the UT pin (the open drain alert outputs are only activated if the temperature exceeds the corresponding threshold for five consecutive update intervals of 3.5ms each). The OT and the UT pin have internal weak 400k pull-up resistors to VCC; no external resistors are required in many applications.

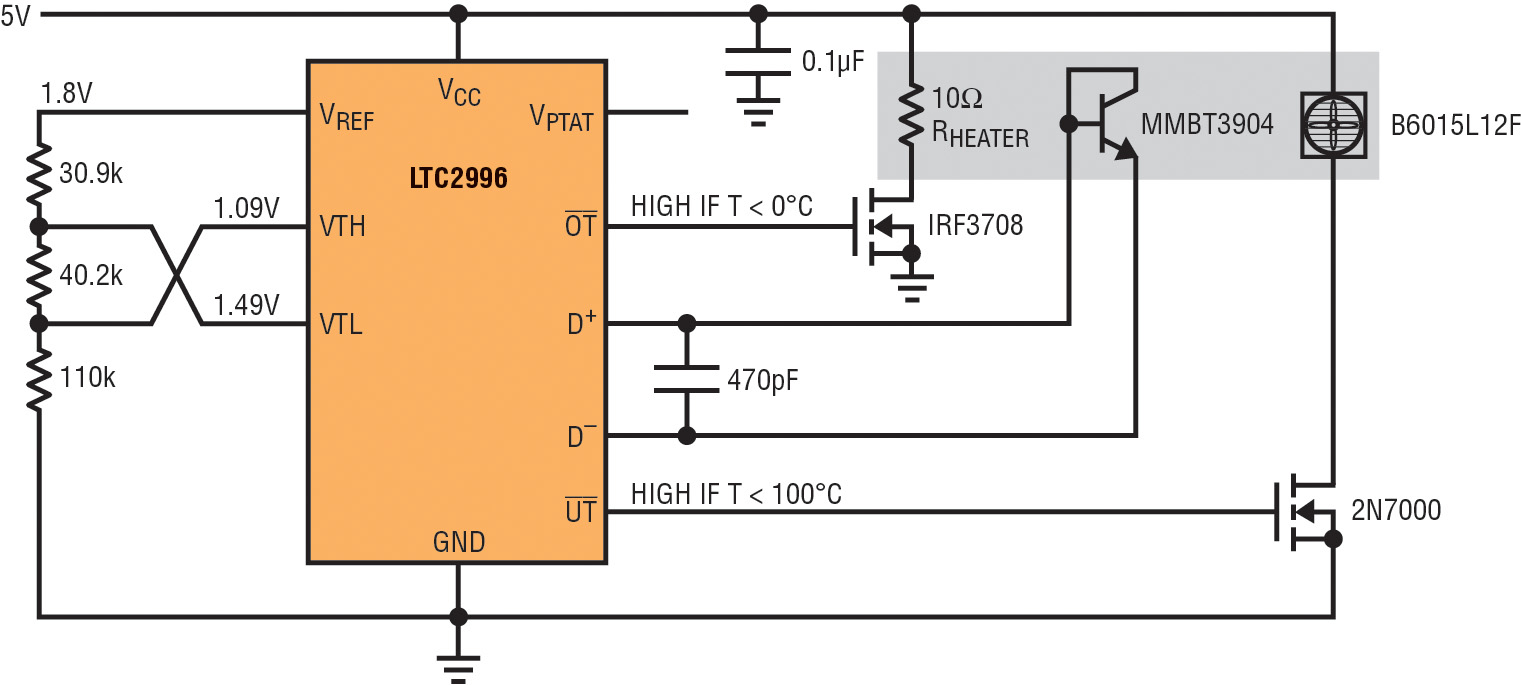

Figure 4 - Bang-bang controller maintains temperature between 0 and 100°C

The LTC2996 can be used to implement a bang-bang controller, keeping the temperature of a sensitive device, such as a battery, in a certain temperature range as shown in Figure 4. In this application, the UT input threshold is set to 100°C, while the OT input threshold input is set to 0°C. This seemingly upside down arrangement is linked to the fact that OT and UT are pulled low when a threshold is exceeded. Therefore, in this configuration, UT and OT both pull the gates of the NMOS transistors low while the temperature remains within the desired range (over the OT and under the UT), and the heating resistor and the cooling fan are turned off. If the temperature rises above 100°C, the UT open drain output is released high and the fan is switched on. Similarly, a temperature below 0°C turns on the heater.

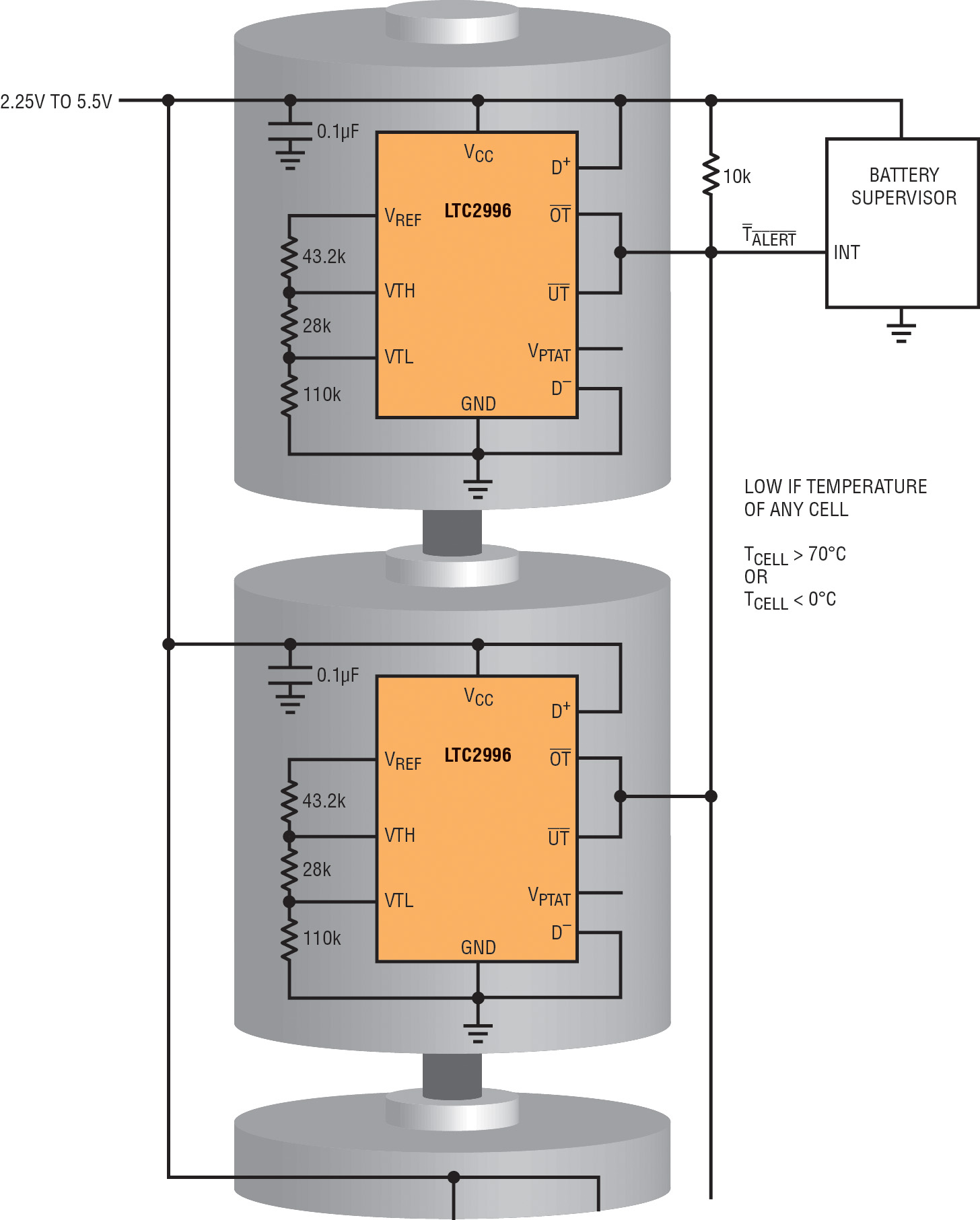

In the context of batteries, the LTC2996 can also be used to supervise the temperature of a large battery composed of several different cells. A damaged, shorted or worn out cell typically heats up and can, in worst case, catch fire. The LTC2996 supervises the temperature of each cell individually with minimal additional wiring, as shown in Figure 5.

Figure 5 - Supervising temperature of cells in a battery stack

In fact, if the cells are connected in series (battery stack) only three additional lines - VCC, GND and an alert output - are required to monitor whether the temperature of any cell leaves the desired operating range. If the cells are connected in parallel and a battery with a terminal voltage between 2.25V and 5.5V (e.g., Li-ion) is monitored, even a single additional line - the alert output - is sufficient to supervise the temperature of each cell.

Voltage monitoring

In addition to temperature monitoring, nearly every electronic system requires multisupply voltage supervision. To serve this need, the LTC2995 combines the LTC2996 with a dual voltage supervisor, monitoring two supply lines for overvoltage and undervoltage conditions. The LTC2995 adds two additional high and low voltage inputs per channel, which are continuously compared to an internal 500mV reference. As soon as the voltage at either VH1 or VH2 falls below 500mV, the LTC2995 flags an undervoltage condition by pulling the UV output pin low. Similarly, an overvoltage condition is indicated by pulling the OV pin low if either VL1 or VL2 rise above 500mV.

To prevent spurious resets due to noise on the monitored supply voltages, the LTC2995’s lowpass filter causes the output of the comparator to be integrated before asserting UV or OV. Any transient at the input of the comparator must be of sufficient magnitude and duration before the comparator triggers the output logic. Furthermore, the LTC2995 has an adjustable timeout period (tUOTO) that holds UV and OV asserted after any faults have cleared. This delay minimises the effect of input noise with a frequency above 1/tUOTO. The timeout period (tUOTO) is adjustable by connecting a capacitor, CTMR, between the TMR pin and ground in order to accommodate a variety of applications.

The LTC2995 includes temperature measuring and monitoring features that provide more flexibility than the LTC2997 and LTC2996. While the latter devices always switch to external mode if an external diode is connected, requiring D+ to be connected to VCC to measure the internal diode, the LTC2995 provides an additional Diode Select (DS) pin, allowing switching between the internal and an external diode on the fly. If the DS pin is left floating, the LTC2995 goes into ‘ping-pong’ mode, where it alternates between internal and external diode measurement with a period of about 20ms.

Finally, the LTC2995 can configure its two temperature thresholds both as OT or both as UT limits using the Polarity Select (PS) pin. This feature allows systems to react in levels to changes in temperature. As an example you might want to get a warning if the temperature rises above 75°C (e.g., to switch on a fan) and an alert if it increases above 125°C (e.g., to switch off the system).

Linear Technology’s new family of accurate temperature sensors/monitors can use an internal or external diode as a sensor and produce analogue outputs proportional to measured temperature. The family ranges from a tiny temperature sensor to a combined temperature and dual voltage supervisor that can signal out-of-range conditions. These devices make it easy to build analogue temperature control loops or to monitor temperatures (and voltages) with minimum complexity.