Sensors for the IoT age

Cliff Ortmeyer, Global Head of Solutions Development and Technical Marketing, Farnell element14, highlights the importance of choosing the right sensor.

The Internet of Things (IoT) enables devices to make intelligent decisions that improve peoples’ lives. However, the real world isn’t digital - these modern systems rely on sensors to feed back the information about their environment that then allows them to make those decisions. When designing ‘intelligent’ systems, choosing the right sensor is critical.

Looking at the offering of component distributors such as Farnell element14, one can see that there is a range of different sensors available today - in fact, 19 major categories of sensors can be identified, as well as additional categories covering transducers and encoders.

Broadly speaking, sensors fall into the following broad categories, each detecting or measuring different physical parameters and each suited to different markets and applications.

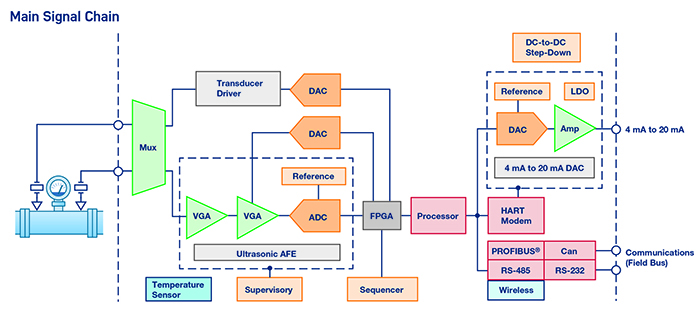

Above: Figure 1. Ultrasonic flow meter process

Physical position and motion, including proximity sensing, linear and angle sensing, accelerometers for detecting motion and orientation (in mobile phones, for example) and position sensors used in motor control and robotics applications.

Light sensors and scanners, covering a wide range of applications from simply knowing when to turn lights on and off in a building or a vehicle, to sophisticated machine vision systems for factory automation.

Fluid and gas sensors, including the measurement of parameters such as level, pressure and flow and the detection of potential fault conditions in industrial process control systems.

Temperature sensors, again covering process monitoring and control in a variety of industries plus heating and ventilating systems in domestic, automotive and building automation environments.

Force, shock, vibration have a range of uses in industrial monitoring and control systems, but also highly applicable to in-vehicle testing in automotive, transport and aerospace applications.

Ultrasonic sensors, often used for distance measurement – with robotics being an obvious application.

Electrical: current sensors for optimising the efficiency of power-supply units or the performance of motor control systems as well as detecting problems in motors and drive systems.

Magnetic: devices such as Hall-effect sensors providing position and revolution information in the harsh environments found in the automotive sector.

Sensor selection

The factors to consider in sensor selection will obviously vary according to the application area, but the key parameters common to many sensor applications can be summarised as follows:

Sensitivity: defined as the slope of the output characteristic curve or, more generally, the minimum input of the physical parameter that will create a detectable output change.

Sensitivity error: a departure from the ideal slope of the characteristic curve.

Range: the maximum and minimum values of applied parameter that can be measured.

Dynamic range: the total range of the sensor from minimum to maximum.

Precision: the degree of reproducibility of a measurement.

Resolution: the smallest detectable incremental change of input parameter that can be detected in the output signal.

Accuracy: the maximum difference between the actual value (measured by a primary or good secondary standard) and the indicated value at the output of the sensor.

Offset: the output that will exist when it should be zero or, alternatively, the difference between the actual output value and the specified output value under some particular set of conditions.

Linearity: the extent to which the actual measured curve of a sensor departs from the ideal curve.

Hysteresis: the measure of how well a transducer is capable of following the changes of the input parameter irrespective of the direction from which the change is made.

Response time: the time required for a sensor output to change from its previous state to a final settled value within a tolerance band of the correct new value.

Dynamic linearity: the measure of a sensor’s ability to follow rapid changes in the input parameter.

Interfacing

Other key factors involved in sensor selection are cost and the ease of interfacing the sensor output with the measurement and control electronics – generally provided by a microcontroller. Interfacing sensors for IoT applications is relatively straightforward as there are really only three types of output - analogue, modulated - using a technique such as Pulse-Width Modulation (PWM), for example - or digital, using industry standard digital interfaces like SPI or I2C.

For meeting the most stringent demands encountered in modern industrial applications, the Analog Devices Blackfin processor is based on a scalable, software programmable 16/32-bit embedded architecture which blends microcontroller unit (MCU) and Digital Signal Processing (DSP) capabilities onto a single chip. Blackfin processors provide a single processor solution for applications where a convergence of capabilities is necessary, such as transducer-based measurement and control processes.

Applications examples

The following sections present some typical application scenarios that illustrate how common transducer types can be used in ‘real world’ industrial applications.

Ultrasonic flow meters

Ultrasonic flow meters are volumetric flow meters that are used to measure the flow rate of liquids, gases or steam. They are commonly found in oil and gas, pharmaceutical, and food and beverage industries. Flow meters use time-of-flight or Doppler techniques to measure flow rate. Flow meters that use the time-of-flight principle have a pair, or multiple pairs, of transducers. The transmission time of the ultrasonic waves is measured in both directions and from this the flow rate can be calculated. This technique typically requires a relatively pure medium with less than five percent particle content. Accuracies of within one percent are achievable.

Using the Doppler approach, ultrasonic pressure waves are reflected off moving particles in the flow. The velocity of these particles creates a Doppler shift in the echo signal, which is used to determine the flow rate. This measurement approach is typically limited to three percent accuracy in real world implementations.

Honeywell and Omron are two manufacturers that offer a range of flow sensors that form the sensing part of everyday flow meters.

Motion sensing using MEMS technology

MEMS (Micro-Electro-Mechanical Systems) technology has been used in the automotive industry for around 20 years for applications such as airbag deployment and automotive pressure sensors, but it took the motion sensing user interfaces featured in the Nintendo Wii and the Apple iPhone to create broad public awareness of what inertial sensors are capable of.

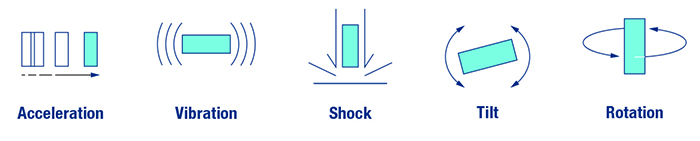

Looking at what becomes possible in each of the five modes of motion sensing - acceleration (including translational movement such as position and orientation), vibration, shock, tilt, and rotation - vastly expands the options beyond today’s high volume MEMS applications.

For example, complicated controls and physical buttons are being replaced by gesture recognition interfaces controlled by the tap of a finger. In some cases, the operation of end products becomes more precise, such as when a compass has compensation for the tilt angle at which it is held in a user’s hand.

There are a number of Sensor Development Kits available that help when designing motion sensing applications.

Conclusion

Sensors come in many forms, and continue to have an impact on the whole spectrum of electronics applications, from heavy industry to the latest consumer and communication devices. With the evolution of the Internet of Things, sensors will continue to influence people’s lives in many different ways. With more sensors now having digital interfaces, designing them in is now easier than ever, allowing yet more new applications to be devised.