Really cool, really efficient

Shrinking PCB areas mean system designers are opting for smaller passive components and up-integrated sensors in switched mode power designs, says Allegro as it introduces its 400kHz current sensors.

Driven primarily by cost and shrinking PCB area, system designers are opting for smaller passive components and up-integrated sensors in switched mode power designs. The space savings of smaller capacitors and inductors comes at the expense of efficiency in the form of switching loss, as higher switching speeds are required to generate an equivalent level of power.

The availability of wide bandgap devices (SiC, GaN, and GaAs) has reduced the impact of switching losses on efficiency. As such, switching frequencies are on the rise in many power applications, including DC-DC converters, solar MPPT and inverters, telecomms and server power supplies, power distribution units (PDUs), uninterruptible power supplies (UPS), and charging stations.

With these gains in efficiency and space savings, the high-speed trend is expected to create new requirements for current monitoring and protection.

Stability and accuracy

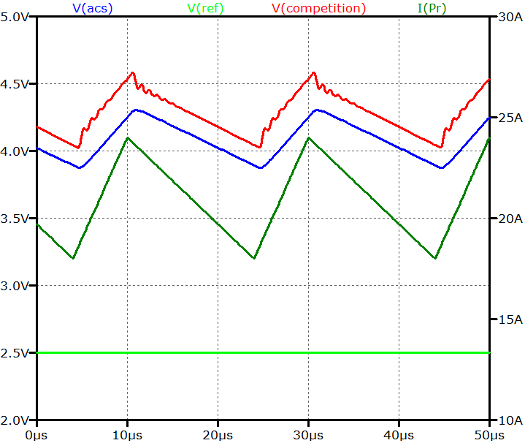

Switching frequency directly affects a power system’s response to transient loads. As power supplies are tasked with supporting multiple subsystems, a proper transient response is required to avoid brownout events as these subsystems come online. When choosing sensors for such applications, system architects typically compromise between high speed or stability and accuracy over frequency and temperature. Compare the unfiltered response of two current sensing solutions in Figure 1.

Figure 1: Comparison of ACS37002 stable output response vs a competing device

An under-damped response creates ambiguity during peak current detection leading to errors in control and a reduction in overall efficiency. Output ringing also triggers over-current events, false shutdowns and “nuisance” faults.

A 400kHz signal path and mature sensor architecture means the ACS37002 cleanly tracks the signal with minimal ringing, phase delay, or attenuation - and no external filter components. A differential output (Vref) and stray field rejection offer high signal integrity in noisy environments.

Efficiency, heating and PCB area

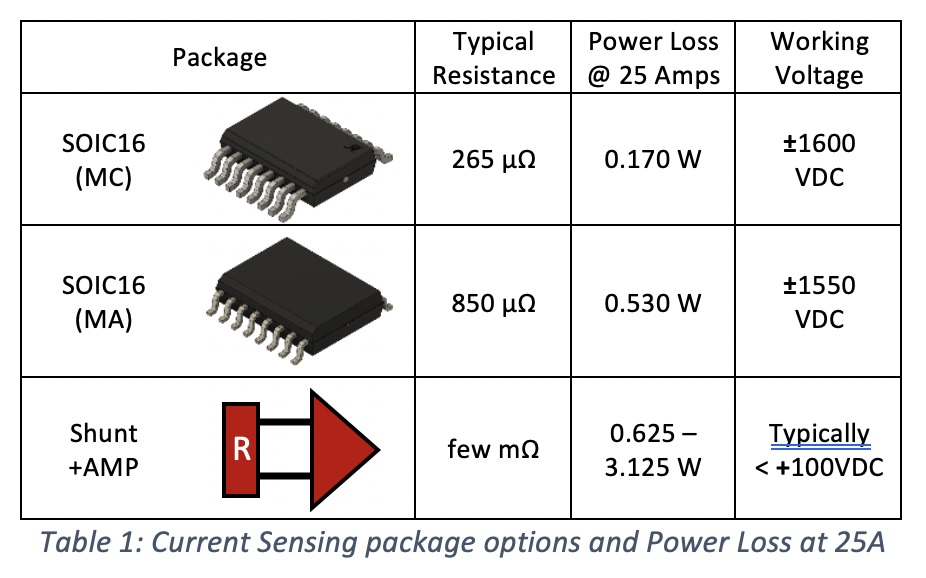

Efficiency goals are also increasing, driving the adoption of low loss switch technologies. As the on-resistance of switches drops, other components in the current path account for a more significant percentage of power lost as heat.

Management of I2R losses has compounding effects on system cost and reliability. Limiting heat reduces cooling requirements and associated costs while extending the lifetime and reliability of power systems (see Table 1).

Power loss in shunt solutions is reduced by placing additional resistors in parallel or choosing lower resistor values. These are useful, but the layout is critical for overall accuracy, and the added resistors consume precious board space. Lastly, most shunt solutions do not support negative input voltages, requiring additional isolation components to make the measurement.

The latest generation of current sensors are easy to use and have features that reduce design time, BoM and cost.

The 400 kHz ACS37002 family of sensors is cool under heavy workloads, with a compact, low power loss package that keeps temperatures down and can extend the life of a power system. They balance speed, accuracy and stability over temperature, making switched mode power designs greener and more efficient - leading to a more sustainable future.

Wade Bussing is Product Marketing Engineer, Allegro Microsystems