Not-so-common sensors

Steve Rogerson looks at recent developments and trends in automotive sensors for ES Design magazine.

As electronic control and demands on safety increase rapidly in modern vehicles, the sensors around a car or lorry are going up both in volume and ability. They are becoming vital components as the quest for the holy grail of autonomous driving continues, but even today’s advanced driver assistance systems (ADAS) rely heavily on sensors of all types. One big change has been the advent of the ISO26262 standard and the associated automotive safety integrity levels (ASILs). While that will not affect directly an individual sensor, the sensors have to be designed in such a way that the whole system can meet the standard.

“Most of our customers are asking for information on whether we are ASIL compliant and to what level,” said Andreas Friedrich, Technical Director, Allegro Microsystems. “The difficulty is that as a semiconductor supplier we can’t answer that because ASIL is a system level specification.” What this has meant is that in many cases dual sensors have to be provided to build in redundancy in case one fails. The other alternative is to add diagnostic information into the sensor so that it can be monitored to check whether it is functioning correctly. “It is cheaper to have diagnostics rather than using two sensors,” said Friedrich. “It also takes up less space and that is key for automotive. Systems are constantly being redesigned to improve the space being used by the sensors. They want to optimise the cost and space for all the different systems.”

Critical systems

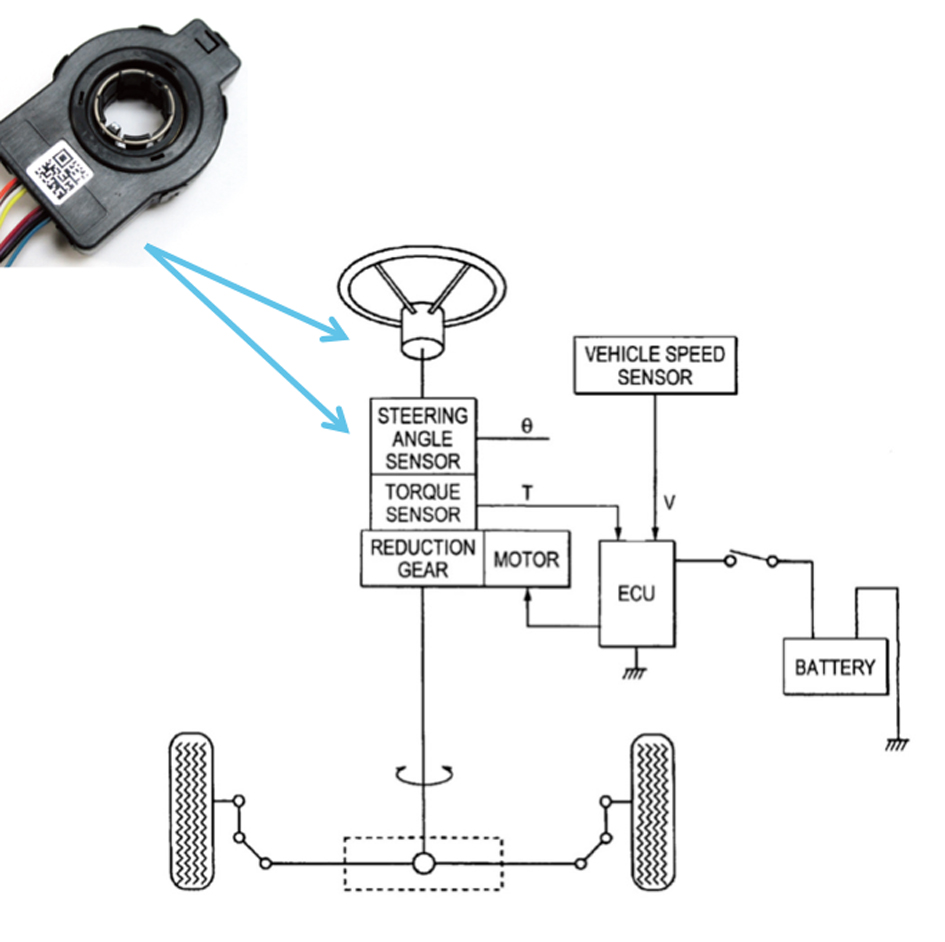

system.jpg)

Electronic power steering (EPS) system

The need for redundancy and diagnostics is found in the more critical systems of a car such as the electronic power steering (EPS) and automatic transmission. “If the steering doesn’t work, then you have a problem,” said Friedrich. “And you don’t want a sensor to fail and put the car in reverse when you are travelling at 100km/h. It will destroy the transmission and you will probably die. So it is critical you have diagnostic information on the sensor.” The added difficulty is that the car makers also want more from the sensors, with extra algorithms that can, for example, enable a speed sensor to differentiate vibration from true rotation; a real example that Friedrich recently faced. This was for EPS and was in a situation where the sensor needed to be on the side of the shaft rather than the end.

“This can bring in an error of up to twenty degrees,” he said, “but the customer wanted a proportional output so we had to design-in linearisation algorithms and that requires processing power and memory; this is a good example of extra content required. The semiconductor industry is always reducing the feature sizes; the ICs should become smaller, but that is never true because the customer is always asking for more content.”

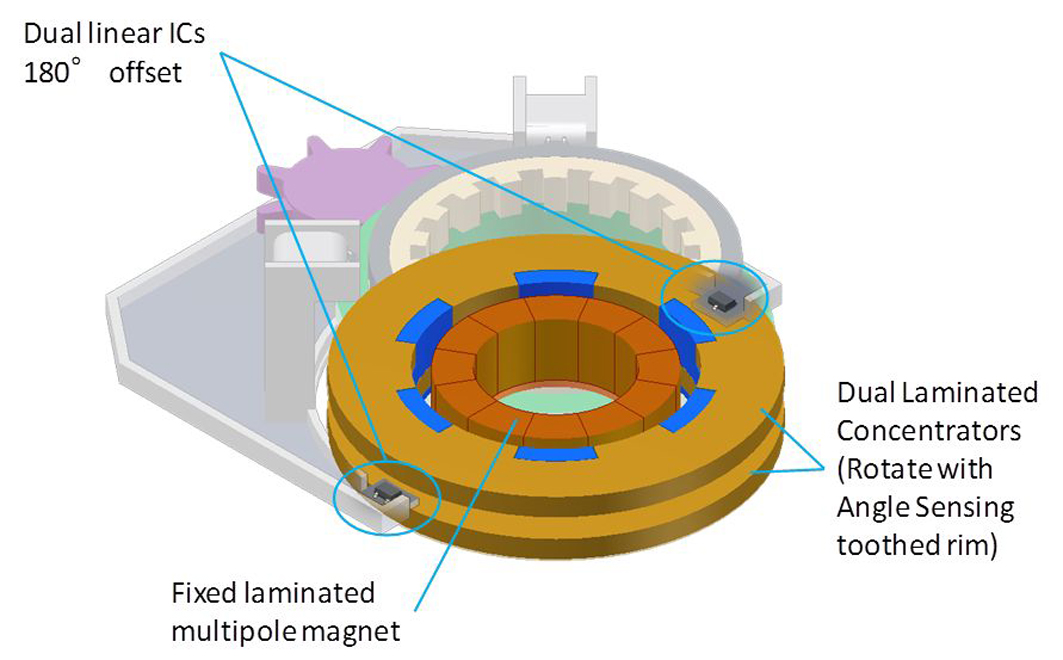

Dual linear sensor ICs for EPS torque sensing

Another change happening with EPS is the move from having the systems column based, close to the steering wheel in the car, to having them based nearer the wheels where they can exert more torque for larger vehicles and trucks. This means that the sensors now have to handle the higher temperatures found under the bonnet rather than in the cabin. “We can do this now for custom sensors,” said TH Swee, Global Product Line Director, TT Electronics. “It will eventually become a standard product when this becomes more popular. The challenge is using the right materials so all parts of the sensor can handle the higher temperature requirements.”

Also, in a bid to reduce size, car makers are now demanding that the normally separate torque and rotational sensors are combined into one unit. And the move to larger vehicles means that the rotational sensors are moving from the normal two and a half turns to three or three and a half turns. “In a car, two and a half turns is enough,” said Swee, “but in a truck they need more turns. We do this by customising standard products.”

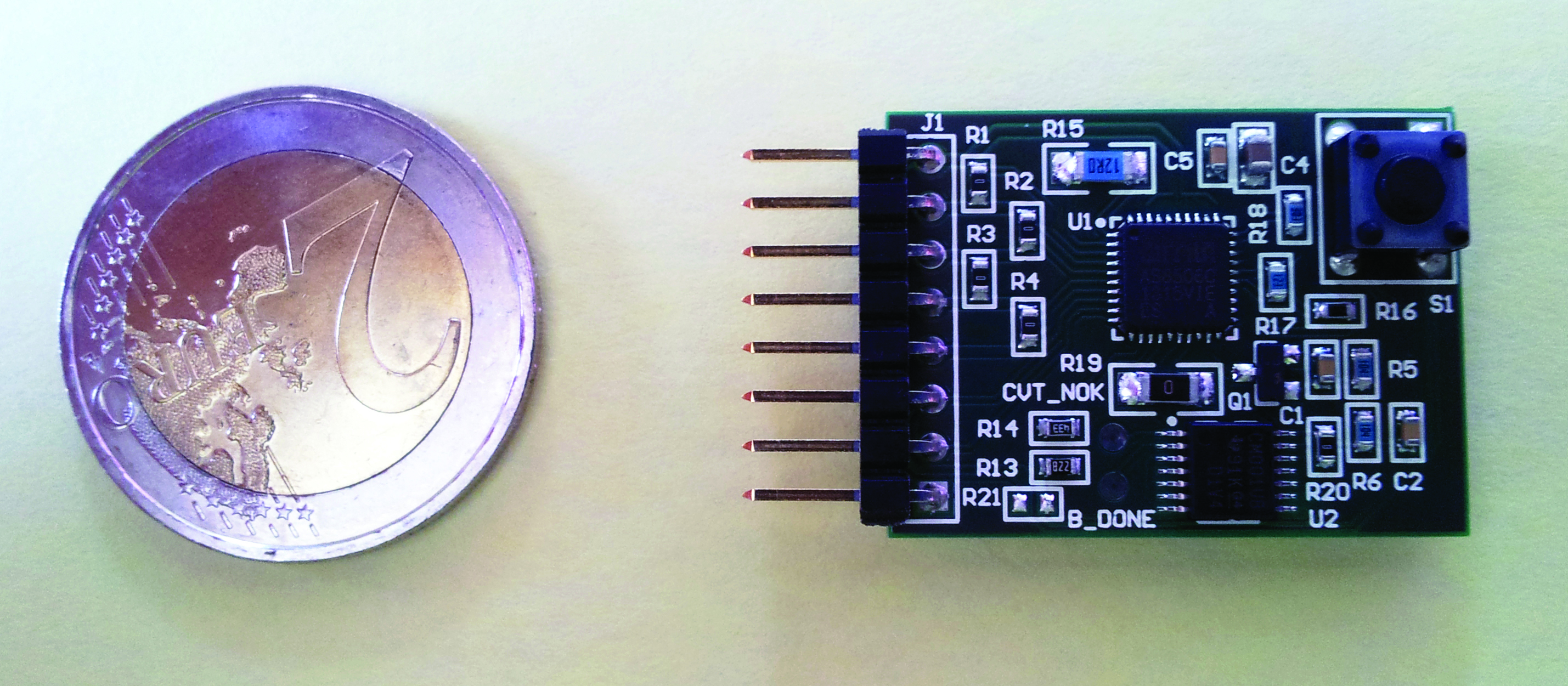

Cost and size are becoming important for sensor systems, such as this battery balancer for electric vehicles

Another demand being placed on sensor makers is to design sensors better able to meet ESD and EMC requirements. “This is crazy and it takes up a lot of space on the silicon,” said Friedrich. “If you take ESD, that can involve huge amounts of energy that has to be dispersed in a short time; we have to make sure it doesn’t blow up the IC. Every OEM has their own tests and we have to design ICs that meet these requirements.” Sensors are also needed in electric and hybrid-electric vehicles for checking the state and balance of the battery. Here, current, voltage and temperature sensors combine, and there is a need to make these more efficient if the range and performance of electric vehicles are to continue improving.

Self-drive cars

Autonomous road vehicles have become a target for many car makers and while legislative and other reasons mean a true self driving car is some years away the move to fill in the gaps to make that possible is already happening. Various ADAS features from cruise control to automatic parking are steps in this direction and all of them are requiring large amounts of sensors so the car systems have information about the outside world.

Camera systems are becoming the norm in many new cars

“The name of the game is the self-driving car,” said Bernd Gessner, General Manager, Automotive, ams. “A lot of the technology for that is available today. All the sensors from different vendors are providing the intelligence that will enable the self-drive car.” Laser and camera based systems are being used for longer distance checking, in lane-departure warning systems and the like. High-resolution cameras can be used for reading road signs. Ultrasonics tends to be the technology of choice for detecting objects close to the car. Inside the car, sensors are needed on the steering wheel to check if the driver is wanting to regain control and on the pedals for the same reason. Cameras inside the cars can check the state of the driver to see, for example, if he or she is falling asleep or reaching for the steering wheel.

Contactless position sensor

Cars are also being given the ability to connect with other cars and the infrastructure to receive information on traffic conditions, road surfaces and so on. “These can all combine so the car can drive itself,” said Gessner. “This will happen within the next ten to twelve years.” One of the main challenges to achieve this is to ensure that the various sensors from different manufacturers can work together. The other big one, of course, is liability. “What happens if there is an accident caused by a sensor failure?” said Gessner. “Who is liable? This will take a long time to sort out.”

Non-contact position sensor used in an EPS system

Meanwhile, the sensor manufacturers are progressing in different ways to achieve the necessary cost and accuracy that will be needed. Radar sensors are already being used in high-end cars, but they need to be made cheaper so they can find their way into small to medium vehicles. Ultrasonic sensors need to be further developed to provide more accuracy. They will though probably stay for just short distance detection as the energy and processing required for longer distances makes them impractical. Likewise, radar and optical systems struggle at short distances. The result of this is that a mix of sensor types looks like being the norm for some time. “The challenge is to combine all these in a way that they work together and with the infrastructure,” said Gessner.

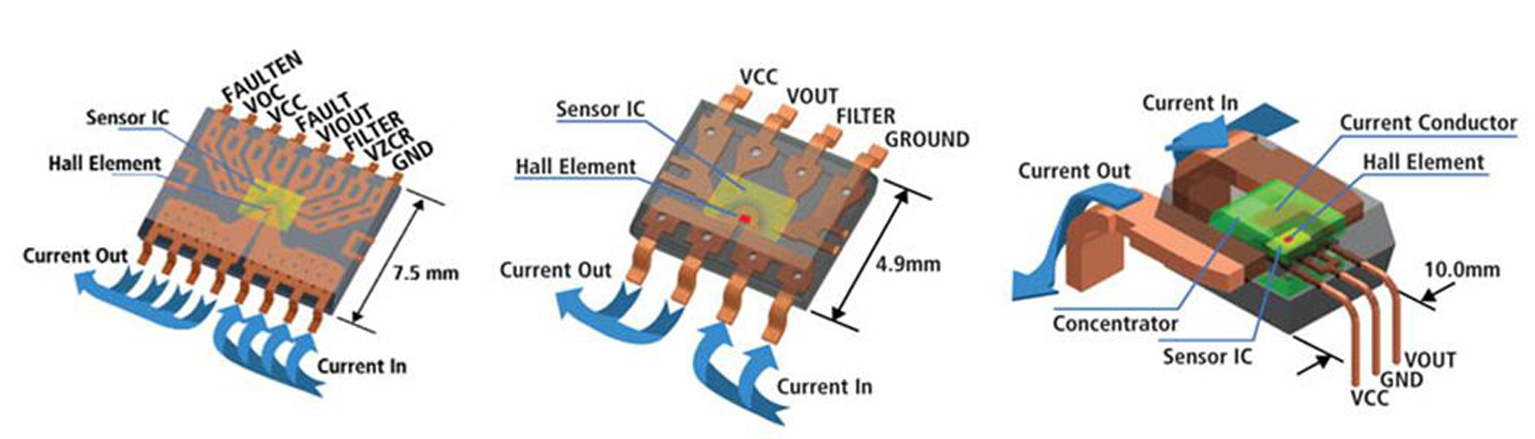

Integrated current sensors for EPS motor control applications

Sensor technology is growing in importance in automotive electronics. What were once speciality components, such as tyre pressure monitoring systems and lane departure warning, are moving into mass market cars, meaning the sensors have to be made smaller and cost less. At the other end, there is a need for more advanced systems as car manufacturers move towards autonomous vehicles. These two factors are increasing the pressure on sensor designers and will continue to do so for the foreseeable future.