Enabling new levels of performance and safety in magnetic sensors with xMR

Electrification in automotive and industrial applications is changing sensing requirements and creating new demands. As automotive and industrial applications advance toward greater autonomy, demand on electrical systems grows, requiring higher-accuracy, smaller-footprint, lighter-weight, and lower-power solutions. Several incumbent and emerging magnetic sensing technologies can meet the bulk of these challenges.

This article originally appeared in the Sept'22 magazine issue of Electronic Specifier Design – see ES's Magazine Archives for more featured publications.

Paul A. David, Executive Director, Chief Technologist, Sensor Innovation, and Alexander Latham, Senior Technologist, Allegro MicroSystems further discuss.

This article compares Hall-effect and magnetoresistance sensor technologies and discusses solutions to leverage these to minimise tradeoffs and meet the requirements of the most advanced emerging automotive and industrial automation applications.

Magnetic sensor technologies

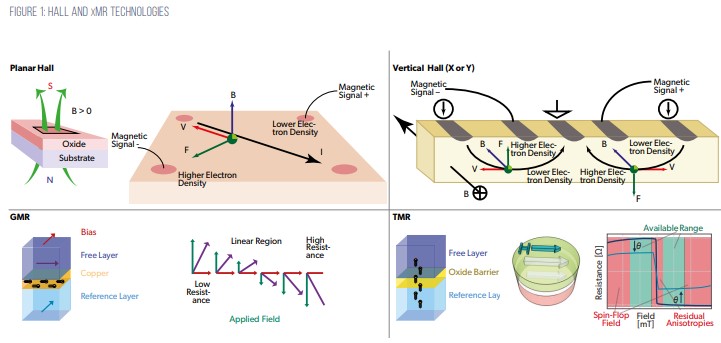

Automotive and industrial sensing applications have long used Hall-effect sensors. Recently, magnetoresistance sensors – including giant magnetoresistance (GMR) and tunnel magnetoresistance (TMR) technologies, referred to collectively as xMR – have emerged. The principles of operation for Hall and xMR technologies are shown in Figure 1.

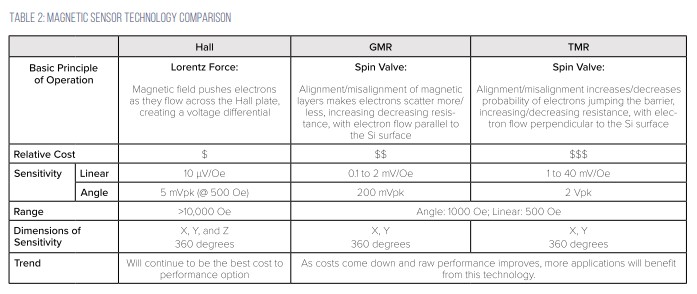

Hall sensors use the Lorentz force, where a magnetic field applies a force that affects the flow of electrons, creating a proportional voltage across the Hall plate as magnetic field is applied. Hall elements can be implemented to allow all directions of sensitivity – X, Y, and Z – on the same piece of silicon through layout of the drive and sense contacts. xMR sensors use spin-valve magnetoresistive transducers to measure changes in resistance that occur with the angle of applied field: a free magnetic layer rotates with applied field. When the xMR stack layers are aligned, the electrons flow more easily. The angle of the free layer relative to the reference layer determines the resistance [cos (∝) R]. Thus, xMR transducers are natural angle sensors that are tunable to the application. Multiple reference directions can be used to create 360° sensors, and adding an external magnetic bias can create a linear response where sin(x) ≈ x.

Technology comparison

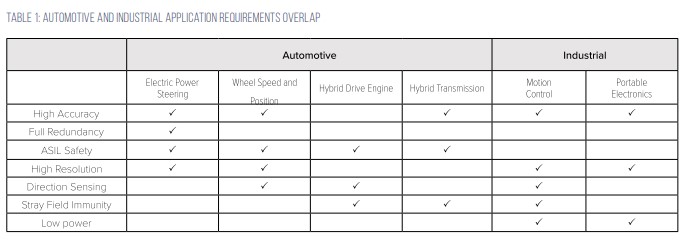

Hall and xMR technologies both have a place in automotive and industrial applications, which frequently converge on similar requirements (see Table 1) for high-speed, high-resolution angle, position, and distance measurements.

The same on-chip diagnostics and dual-die options that meet ASIL D requirements in automotive applications can enable functional safety in industrial applications.

Hall technology integrates into most standard Bi-CMOS ICs and is cost effective, but its relatively low sensitivity can result in lower signal-to-noise ratio (SNR), tighter mounting and air gap tolerances, and susceptibility to stray magnetic fields. xMR can improve the SNR 10× to 1000×, with higher stray field immunity, larger air-gap performance, reduced jitter (higher accuracy), wider installation tolerances, and low-power capability. The tradeoffs between Hall and xMR technologies are summarised in Table 2.

The best technology choice may lie in value-added features, like algorithms for high accuracy, packaging for environmental robustness, or hybridised sensor solutions.

Allegro MicroSystems is able to hybridise the solution to provide value-added sensors, including:

- Vertical Hall technology (VHT) incorporating vertical and planar Hall-effect elements with sensing axes orthogonal to one another, providing 90° of phase separation independent of magnet pole spacing and air gap

- xMR products where the direction of the electron flow can be adjusted in both the reference layer and the bias layer

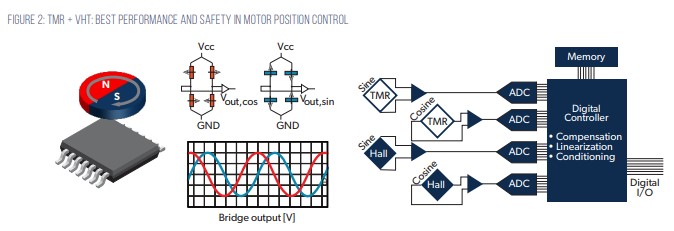

- TMR + VHT (see Figure 2) products, which are the first to include VHT with TMR in a single sensor package.

The TMR + VHT family includes the A33110 [¹] and A33115, [²] which provide high-resolution (> 12-bit noise-free resolution) position, speed, and direction measurements with heterogeneous redundancy of transducers to critical applications to ensure diagnostic coverage for safe operation in compliance with ISO 26262 ASIL D requirements, reducing the likelihood of dependent failures.

Conclusion

When considering magnetic sensor solutions, the best sensor may incorporate value-added features – like algorithms for high-accuracy and packaging for environmental robustness – or hybrid designs that merge multiple sensor technologies in a single package, such as the solutions from Allegro.