Seeking an energy harvest for the world

Designing efficient power devices, especially those used within the IoT, presents challenges in design. The quest for a truly self-powering technology may be aided with some strategic partnerships, says Caroline Hayes.

There are billions of IoT devices in operation today, which means dependency on batteries is growing, warns AND Technology Research. Energy harvesting at the source of where power is needed is seen as one of the keys to ensuring a sustainable IoT industry.

The IoT development consultancy helps customers develop products for the IoT. As well as testing and compliance support via its tento software tool, it can support development projects with custom boards and sensors and its c2 IoT product development software.

The UK company has been a Renesas design partner “for decades” and has announced a collaboration with the University of Essex to explore new ways of reducing the amount of power a device needs. The project, initiated this year and scheduled to run until 2023, is also looking at using energy harvesting techniques to produce “truly self-powering devices”.

The project is partly-funded by Innovate UK. It intends to develop a completely self-powering, battery-less IoT device, that uses AI at its core. Algorithms will be used to monitor and control the intelligent management of energy sources, using multiple sources to harvest power.

The device will be built on the c2 IoT platform and use Renesas’ SOTB (silicon on thin buried oxide) technology.

It will address technical challenges facing energy harvesting, namely lowering the in-rush current required, reducing charging times and increasing performance. Using multiple power sources and an AI algorithm, the device will make intelligent decisions on when to charge in different environments. This, says AND Technology will pave the way for innovative use cases, such as wearable devices, wellness trackers, smart cities and remote monitoring in industrial and commercial applications.

The c2 software supports customers across the product development process, from the initial idea all the way to manufacture and commercialisation.

CEO of ANDtr, Dr Nicola Thorn said:“This project will open up a whole new world of possibilities of AI and energy harvesting.

“We believe self-powering, battery-less devices will be the next game-changing technology to be unlocked in the world of IoT, and we aim to position ourselves at the forefront of the market. Self-powering, battery-less systems have potential applications in any industry where continuous monitoring is required – from medical and agriculture to fleet management, but we are particularly interested in the potential healthcare benefits.

“For example, remote continuous monitoring of patients with chronic health conditions will reduce patient morbidity, enable patients to better understand their conditions and seek intervention at an appropriate point and reduce the need for face-to-face interactions with clinicians - thereby reducing resource implications for the NHS,” she explained. “Long term predictions foresee wearable technology to contribute to global cost savings in the order of $200 billion in the healthcare sector. But it doesn’t stop there, there are also many applications to improving sustainability.”

AI in the IoT

Battery technology has advanced in the past five years, with significant improvements to battery life and energy density, but these advances were only possible due to an increasingly exotic list of new compounds. These compounds are sourced from around the world and are considered dangerous to mine. They can also be dangerous to handle and process; lithium, in particular, has incredibly explosive properties, and other key metals such as cobalt, cadmium and manganese are also hazardous when handled.

For batteries with high discharge rates have additional challenges. Non-rechargeable batteries, typically las three years and rechargeable versions struggle to go beyond 10. Disposal of these batteries can be difficult and a risk to the environment, especially if that process is not handled properly. Replacing these batteries brings further costs and repeats the cycle of risk and waste, and in many cases, danger for workers. Energy harvesting at the source of where power is needed is one of the keys to remedying this problem and will play a crucial role in ensuring a viable and sustainable IoT industry, says the company.

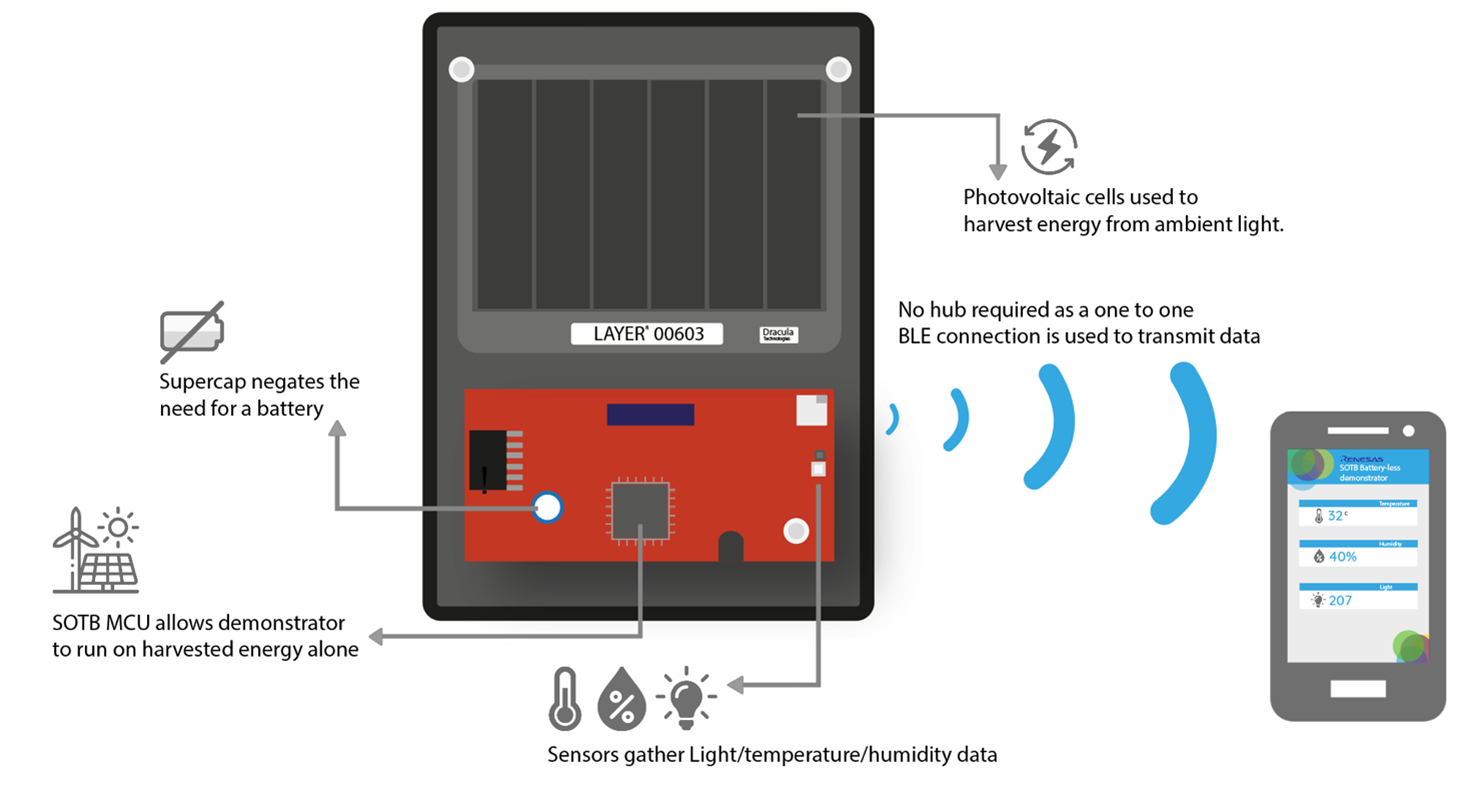

Figure 1: The energy harvesting demonstrator, developed by AND, using Dracula Layer printed technology and Renesas RE SOTB microcontrollers.

University collaboration

AND will supply hardware and software development expertise in this project and will work with Dr Morteza Varasteh and Dr Hossein Anisi, from the University of Essex’s School of Computer Science and Electronic Engineering. Dr Anisi is head of the Internet of Everything laboratory at the university.

“My main focus is on developing systems capable of reliable and seamless generation, transmission and processing of data,” commented Anisi.

“Self-powering devices are the way forward, but although there has been some progress in making them a reality, we are not quite there yet. This partnership has potential to make a real difference to the way we all use the internet, sensors and electronic appliances, from wearable health monitors and smart buildings to intelligent trackers for perishable foods,” he added.

Both Varasteh and Anisi have extensive experience of tackling the dual challenge of developing low-power IoT devices and exploring alternative sources of energy from using the sun, vibrations within a human body or radio waves to provide power. They will supervise a full-time researcher, who will work on the project at the AND offices in Theydon Bois, Essex.

Earlier this year, AND announced the energy harvesting demonstrator developed with Renesas and Dracula Technologies. The demonstrator uses Renesas Electronics’ low power RE microcontroller family, based on its energy-harvesting SOTB technology. The demonstrator also has two integrated environment sensors. It sends messages over Bluetooth Low Energy to a mobile app, where the data can be visualised. The demonstrator captures light energy (indirect natural and/or artificial one) from Dracula’s Layer OPV (organic photovoltaic) module and is capable of sending multiple messages every minute on a sunny day without the need for a battery. The OPV harvester also performs well in a dimly lit room, says the company, where it is capable of sending a message every three to five minutes. Through charging super capacitors, the technology is able to charge from entirely renewable energy sources and discharge the energy efficiently ensuring high performance.

Renesas’ proprietary SOTB technology overcomes significant technical challenges of self-powering devices requiring far less in-rush current (the power needed to start up a device) than a traditional microcontroller. This means that RE microcontrollers implemented on the SOTB technology can use a combination of extremely low standby and active power, switching efficiently between modes and reducing the consumption requirements. The RE microcontrollers also implement an on-chip energy harvesting controller for easy connection to solar cells and other harvesting technologies. The Dracula Layer technology is a printed technology that generates energy from ambient light using OVP inks which is made from only organic materials. It does not require rare earth elements which are necessary in conventional batteries.

A self-powering sensor is just the start of suite sustainable energy harvesting devices to come, promises AND Technology.

“[This project] brings together a full range of different innovation; our c2 IoT platform; Dracula’s . . . energy harvesting; and Renesas SOTB reducing the maintenance required and significantly extending the product lifetime, while also addressing many of the concerns around the continued use of battery technologies,” said Thorn. “It’s excellent to see it all come together, and I am very excited about where these technologies can grow,” she added.