The conversion conundrum – LLC or flyback?

Many high-efficiency power supply implementations could use either an active clamp flyback (ACF) converter or an LLC switcher IC to meet design goals. It depends on the final requirement, explains Aditya Kulkarni, Senior Product Marketing Manager, Power Integrations.

This article originally appeared in the September '22 magazine issue of Electronic Specifier Design – see ES's Magazine Archives for more featured publications.

Some designers base their choice on personal preference, familiarity, or historical use of one type or another in specific applications. Faced with two or more possible solutions, the optimum choice lies with sound engineering reasoning, design requirements and prioritisation of product efficiency, size, BoM cost, power density and ease of design.

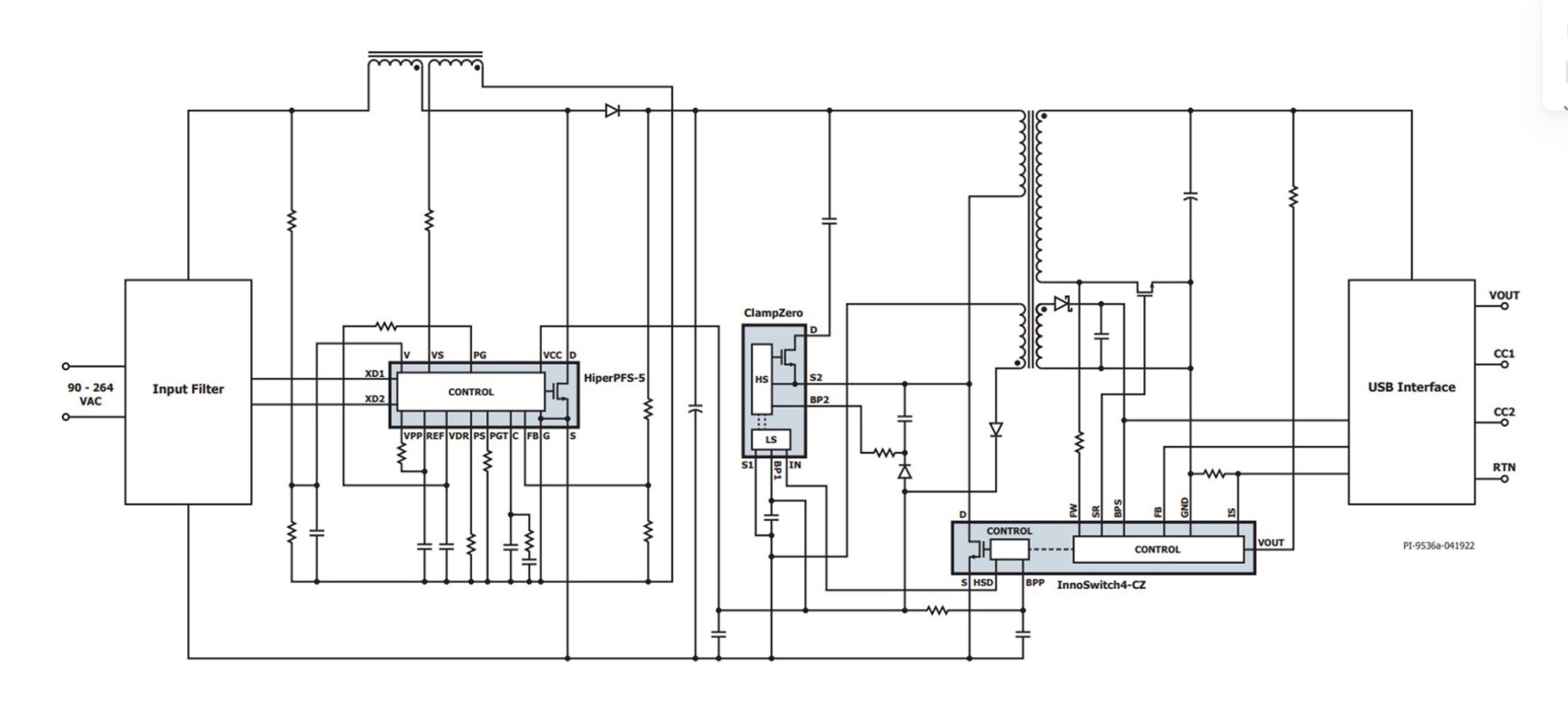

Figure 1. PFC + flyback power conversion using HiperPFS-5, InnoSwitch4-CZ and MinE-CAP technology. (Reference design DER-957)

In favour of flyback

The isolated flyback topology is the simplest to implement. For example, the InnoSwitch flyback controller ICs use Power Integrations’ FluxLink magneto-inductive coupling technology which enables secondary side control to be delivered with the simplicity and low component count usually associated with primary side regulation. This allows synchronous rectification to be added, resulting in efficient performance across the full load range with very low no-load consumption. It also improves reliability because FluxLink makes optocouplers redundant and allows both primary and synchronous rectification switching stages to be operated without cross conduction.

The InnoSwitch flyback ICs are available with a variety of voltage silicon, GaN and – for automotive applications – SiC switches. For example, the InnoSwitch4-CZ, and ClampZero active clamp IC, both GaN-powered, with the HiperPFS-5 PFC stage can be added to deliver the smallest commercially-deliverable USB PD-compliant mobile device charger (see Figure 1 above).

The InnoSwitch4-CZ family incorporates a 750V PowiGaN switch, primary and secondary controllers, ClampZero interface, synchronous rectification and safety-rated feedback in a single, compact InSOP-24D package. A steady-state switching frequency of up to 140kHz minimises transformer size, further increasing power density.

This chipset combination provides up to 95% efficiency and maintains very high efficiency across line voltage, system load and output voltage selected with variable frequency asymmetrical control of the active clamp with intelligent zero voltage switching. This enables both discontinuous and continuous conduction modes across the entire operating envelope. The flyback switcher ICs enable CV/CC accuracy, independent of external components and consume less than 30mW no-load including line-sensing, safety and protection features.

LLC – for maximum efficiency

For higher levels of efficiency, Power Integrations' HiperLCS-2 chipset and a half-bridge resonant switch or LLC topology can be used for compact power supplies and adapters. This configuration uses resonant switching to eliminate switch transition losses and will increase efficiency levels by at least 2% more than achieved by even the best flyback designs. One part of the HiperLCS-2 chipset is an isolation device with a high-bandwidth LLC controller, synchronous rectification driver and FluxLink isolated control link.

This is combined with a separate half-bridge power device using Power Integrations’ 600V FREDFETs (fast-recovery epitaxial diode FETs) with lossless current sensing and high- and low-side drivers. Both are housed in a low-profile InSOP-24 package. The integrated, energy-efficient architecture eliminates heatsinks, part-to-part variations and reduces component count by up to 40% compared to discrete LLC designs.

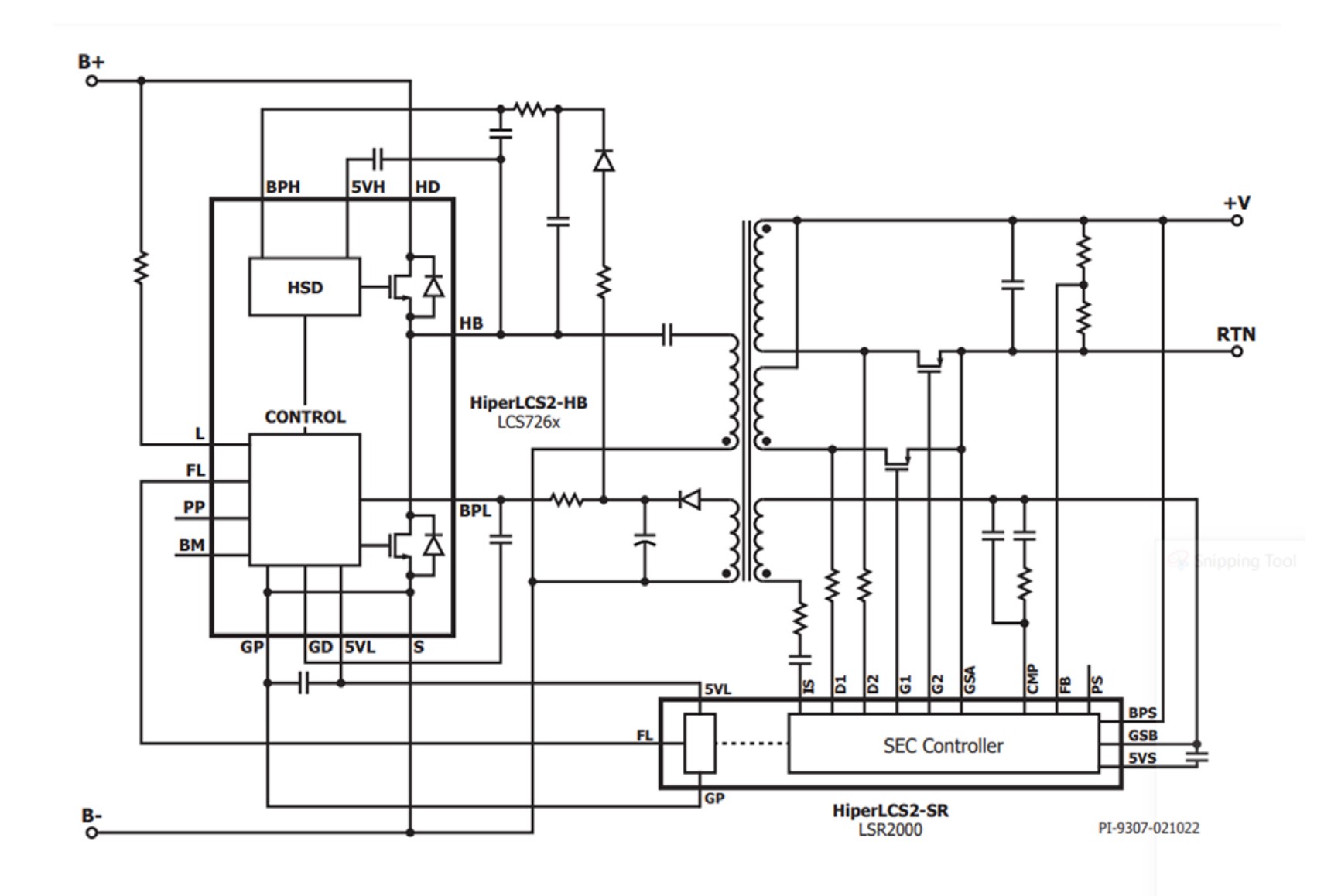

Figure 2. LLC design using HiperLCS-2 chipset (reference design DER-672)

Power supply designs based on the chipset can deliver 250W output power with over 98% conversion efficiency. No-load input power is less than 50mW at 400V DC input and devices provide a continuously regulated output even at zero load, easily complying with the most stringent no-load and standby efficiency regulations. Operation is at high efficiency across the load range with low dissipation; direct heat transfer through the FR4 PCB is all that is required, eliminating heatsinks in adapter designs up to 220W continuous output and delivering up to 170% peak power for short periods. All HiperLCS-2 devices have self-powered start-up and provide the start-up bias for a PFC stage using HiperPFS ICs.

Secondary side sensing provides less than 1% regulation accuracy across line and load range and across production (Figure 2). Additionally, FluxLink technology for safety isolated, high speed digital feedback control provides faster transient response and superior long-term reliability compared to optocouplers. The HiperLCS-2 control engine also provides a progressive burst mechanism and control technique to prevent the need to use increased filtering due to any risk of high output ripple during standby.

Flyback and LCC strengths

If efficiency is the ultimate priority over other factors such as ease of design, production, and operation, then LLC resonant converters are the best choice. LCC converters begin at 250W and can be used in applications up to several kW whereas flyback models reach their limit at 250W. Transformer size and primary switch current (somewhat mitigated by the low RDS(ON) of GaN switches) mean that going much beyond 250W may require a different approach for flybacks.

The needs of subsequent designs and design portability is another factor to consider when determining which platform to adopt. Both are efficient and can offer a low BoM count. For USB PD chargers and adapters USB PD applications with a very wide output range (5.0, 9.0, 12, 20, 28V) flyback is typically the way to go. For the best possible efficiency, an LLC solution is recommended.