Speed up system design

Using modular, configurable power supplies can accelerate system design, advocates Kevin Pamenter, Excelsys Technologies

There are many issues involved in integrating power supplies into system design. Three typical approaches are custom, in-house and standard off-the-shelf designs. These are often implemented at the end of the system design and they have the serious drawback of causing major disruptions in the process if the power supply requirements change, which they often do. An alternative, is to use modular, configurable power supply from the very outset of the project. Advantages of this approach can be lower development costs and a dramatic reduction in time to market.

Traditional power supply design

Complex electronic systems in industrial and medical applications require the use of many DC voltages to power a host of sub-systems, including computing devices, memory, display, electromechanical actuators, sensors and many others. Depending on the application, the power supply will require compliance with stringent standards and a number of international regulations.

The traditional development process, using an array of bench power supplies provides a degree of flexibility as the design progresses and requirements change. Bench supplies however do not accurately reflect the real-world conditions that the final system will experience. Consequently, there is an added element in the design cycle that is required to integrate power supplies into the system design that enables them to meet both the operational needs as well as compliance with the appropriate standards.

System engineers must focus on the core technologies of the design, which often results in the leaving the integration of the power supply into the system to the end of the design phase. As the design moves toward conclusion, the engineers are confronted with finding a way to "fit" the power supplies into the system.

The challenge of incorporating the power supply into the final system configuration begins with dealing with the issues of space, weight and thermal considerations. These are basic requirements, although bench power supply development does not address a range of other considerations, which are essential for effective design.

The first of these is energy efficiency. Global standards on energy efficiency are increasing at a staggering rate. There are 21 energy efficiency regulatory agencies and standards in North America alone. The regulations cover both operating efficiency and standby power consumption. Some standards are mandatory while others are guidelines.

The PSMA (Power Sources Manufacturers Association) has published, and maintains, a comprehensive database of global energy-efficiency standards. They can be viewed at www.psma.com.

Another consideration is safety approvals. Power supplies fall under the IEC60950 (ITE) and IEC60601 (medical) standards for safety. The standards cover leakage current, circuit board creepage and clearance for starters and a plethora of other considerations. For power supplies intended for use in medical applications, strict patient safety standards also apply.

Standards for both conducted and radiated emissions are becoming stricter. This is due to an ever-increasing number of wireless devices and systems in both industrial and medical applications. Radiated emissions from power supplies must be limited to reduce potential interference to other devices that are in proximity, to reduce interference to the device from other sources, and to reduce self-jamming of the product by its own emissions.

The addition of industry-specific filters in the system is often a good idea at the system level. Even if the power supply does not need it to comply with some standards, systems may need them in certain end applications such as MIL STD 461F. There are many specific filters targeted for medical (i.e. low leakage), industrial and hi-rel, defence or aerospace (typically MIL STD 461F) compliance. In these cases, it is best to work with the power supply applications team collaborating with a known filter supplier in order to achieve first-pass success in the EMI compliance certification lab.

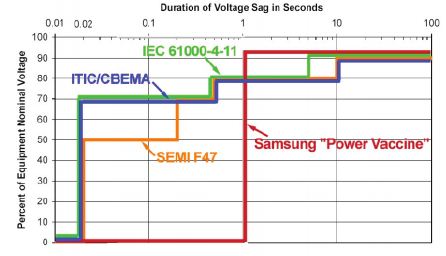

Power line variations also need to be considered early in the design phase. Continuous operation under varying line-voltage conditions, such as hold-up time during short-term voltage sags and longer-term brownout conditions, are mandated by industry standards. The most common standard is IEC 61000-4-11 which defines immunity levels and test requirements. (Figure 1)

Figure 1: Sag immunity requirements for common power supply standards, are defined in theIEC 61000-4-11

Figure 1: Sag immunity requirements for common power supply standards, are defined in theIEC 61000-4-11

In some applications, even more stringent requirements are prescribed. For example, in semiconductor processing applications, the SEMI F47 standard for the semiconductor equipment industry requires operation (sag immunity) for even lower input voltages. One of the most stringent standards, the Power Vaccine, developed by Samsun Semiconductor, exceeds SEMI F47 requirements and requires that semiconductor manufacturing equipment is able to tolerate a complete loss of power for a duration of one second. Power Vaccine requires ride-through for short-term voltage interruption.

Reliability

Always a principal expectation in hi-rel applications, up-time demands for electronic systems is also becoming increasingly important in consumer, industrial and medical applications. System downtime can be costly, so power supplies must have proven reliability.

The required mean time between failure (MTBF) and mean time to failure (MTTF) are calculations that can only be provided as the result of actual test results. Simulations are worthwhile, but demonstrated data and information from field returns over time, as well as highly-accelerated life test (HALT) and highly-accelerated stress screening (HASS) testing on the product, is even better. The MTBF calculations based on Telecordia SR332 MIL STD 217 is the usual and customary standard in this case.

Designers also need to consider isolation. To assure compliance with leakage requirements in magnetics, as well as creepage and clearance requirements in optical and other isolation schemes, requires hi-pot (dielectric) testing of the power supply. For medical applications this is often 4KV AC with margin, which means that testing is often done at over 6kV to ensure margin. Additionally, 2x MOPP (means of patient protection) is becoming commonplace in the industry.

Input surge testing is another area that needs to be addressed at this stage of the power design.

There are many input transient surge tests, depending on what is necessary to achieve compliance. Transients and surges can prove to be huge problems since a proximity lighting strike or an emergency generator in a hospital with centrifugal contactors can unleash havoc in systems. Although commercial power supplies have protection installed, some systems need additional protection to survive these events. There are numerous standards and specifications; but, again, it is best to work with a power supply manufacturer's applications team to ensure meeting the requirements of a specific industry or application.

As medical electronics systems are deployed into emerging economies where utility power is noisy and unpredictable, it is best to pay close attention to these considerations at the systems level.

Ultimately, the power supplies that will be built into the final system should be designed to operate for the life of the system. Commercial power supplies typically have warranties that essentially speak to the manufacturer’s willingness or ability to guarantee the quality and performance of its supplies. The longer the warranty, the better chance the unit will meet this objective.

In addition to some the above concerns that can affect the system, there are even more environmental issues that are often covered by a good warranty, with five-year warranties becoming a benchmark.

Designing with modules

Modular, configurable power supplies are designed with a base unit that is designed to meet the operational standards required of the specific application. This type of power supply has the capacity to accommodate multiple output modules with expected power outputs and voltages needed, the I/O isolation requirements, operational features, and advanced functions, such as sequencing. The compelling benefit of this approach is that upon completion of the bench design, the power supply requirements are fully incorporated and transferable to the system production without further design requirements

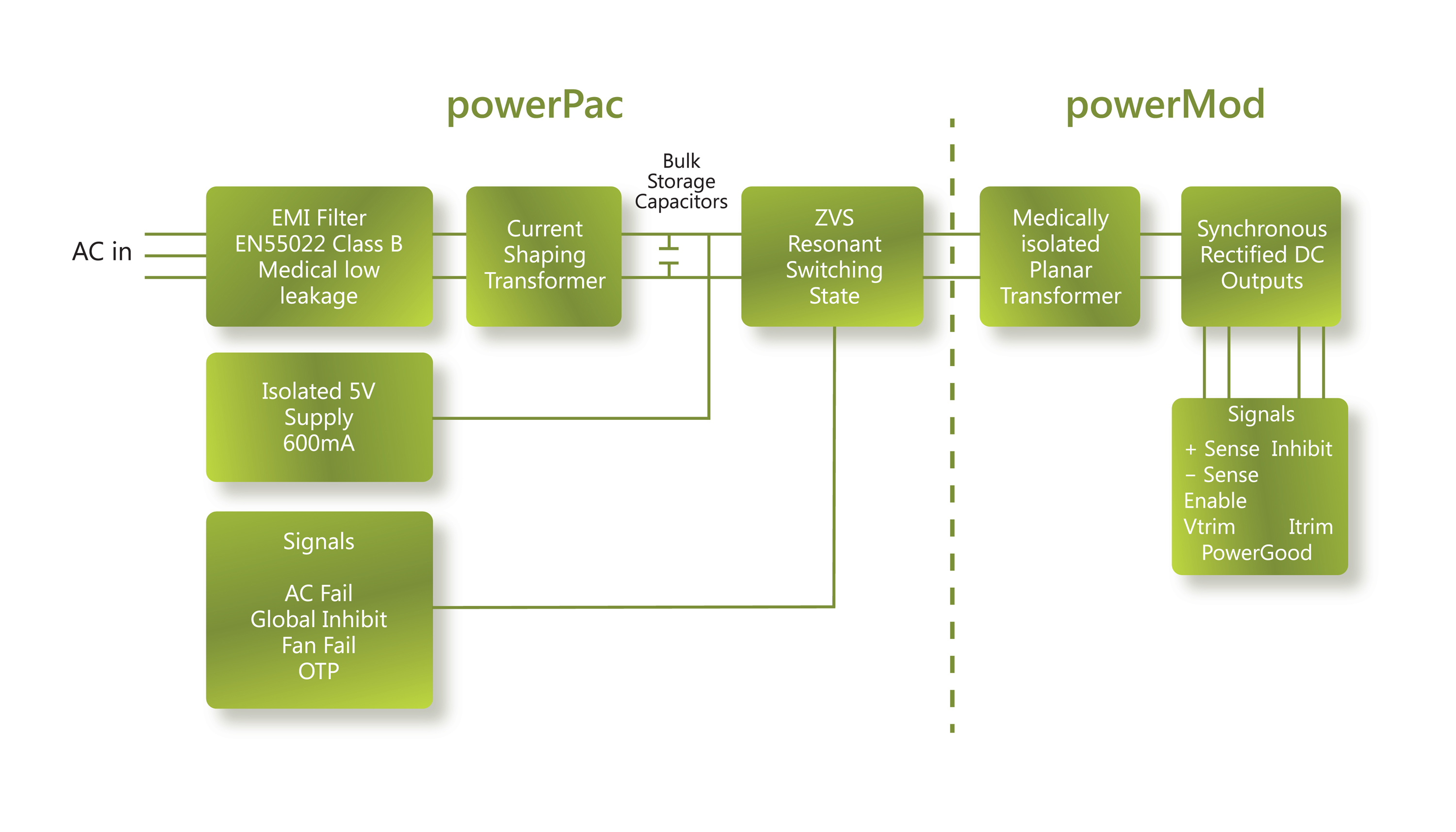

Figure 2: Operation block diagram of a modular, configurable power supply

Figure 2 provides a functional description for a modular, configurable power supply comprising a base unit and a selection of DC output modules that provides a completely modular and configurable system power solution.

The base unit consists of a semi-enclosed chassis containing circuitry for an off-line single-phase AC front end, EMI filter, cooling fan, customer interface and associated housekeeping circuits.

Input AC voltage (L1/N, L2 and GND) is applied to an IEC320 type input connector and then through an EMI filter designed to meet EN 55022 Level B. For medical applications, the EMI filter also ensures the power supply meets the low earth leakage current requirements of EN60601-1 (3rd Edition). An active soft-start circuit limits inrush current. This stage is then followed by a high-frequency switching input current that shapes the boost converter feeding the ZVS (zero voltage switching) resonant switching stage.

The ZVS stage supplies power to the selected DC output modules that provide the desired low-voltage, regulated outputs. This results in reduced size for magnetics and capacitors, excellent line and load regulation, wide adjustment range for output and low EMI/RFI emission.

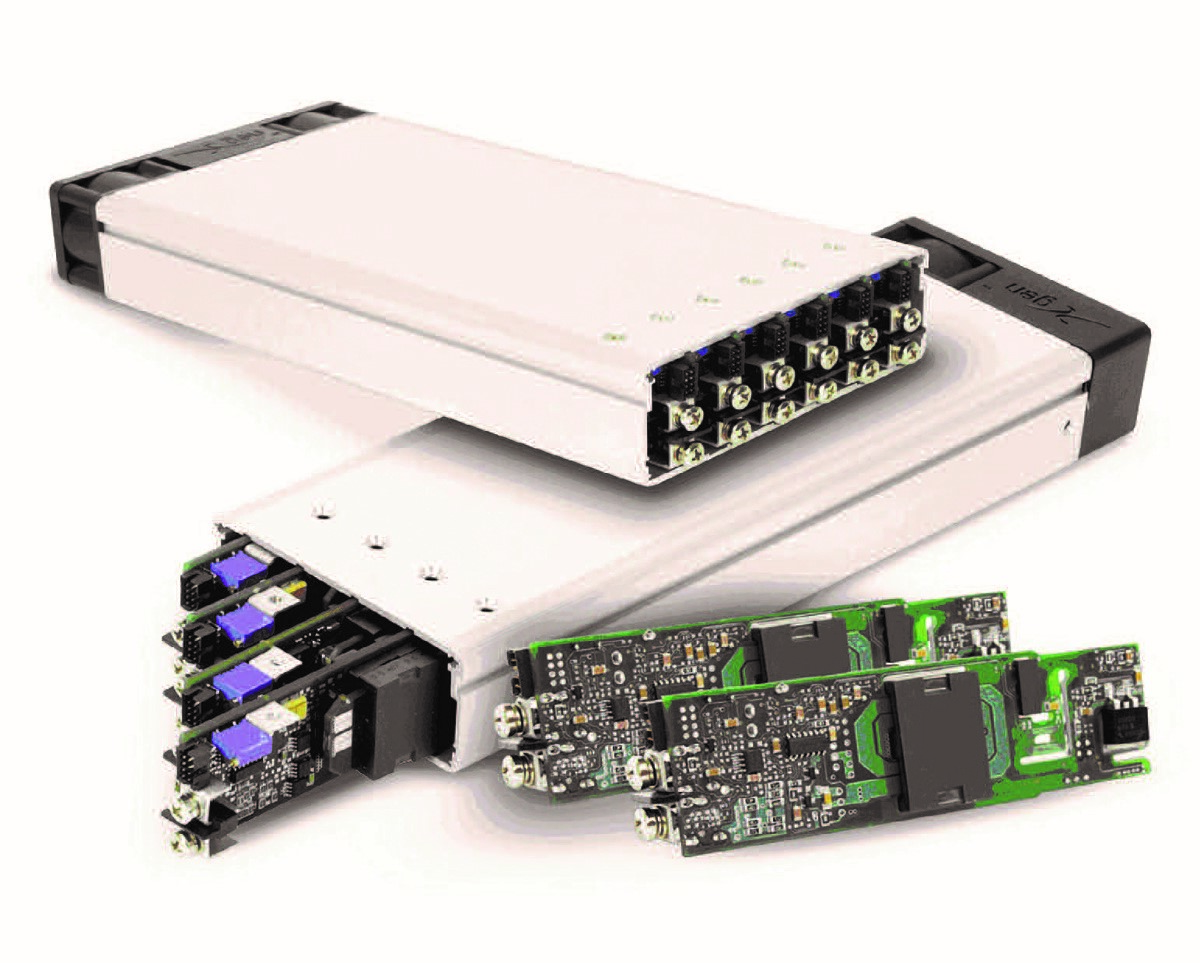

The UltiMod series (show in Figure 3) from Excelsys Technologies is an example of a modular, configurable power supply design. It offers system developers a comprehensive power supply solution that can be applied from the earliest stage of product development and then ported seamlessly into the final system configuration.

Figure 3:1U-packaged UltiMod Series power supplies are offered in six- and four-output versions

Figure 3:1U-packaged UltiMod Series power supplies are offered in six- and four-output versions

The UltiMod Series is designed for highest efficiencies (up to 91%) and consists of two input AC front ends (powerPacs) and a wide range of DC output modules (powerMods) in a compact 1U form factor package. All have a five-year warranty.

Selecting an experienced supplier that understands the myriad safety and environmental requirements is vital for effective, reliable power system design. Backed by a five-year warranty, the UltiMod series offers a cost-effective example of this type of modular, configurable power supply design, providing options to meet a choice of end application uses and standards.