Relay design evolves to address new applications

Electromechanical relays are continually evolving and adapting to meet the requirements of new generations of applications. For example, longer endurance power relays are needed to address smart meter applications and devices that can withstand higher inrush current are required for inductive load applications like energy efficient lighting.

Author: Andries de Bruin, Senior European Product Marketing Manager, Omron Electronic Components Europe

At the same time, relays are subject to the same cost and size pressures as other components. Addressing all of these issues successfully tests the relay engineer’s ingenuity to the maximum. Contact material, contact design, coil insulation and housing material are just a few of the areas which need to be adapted to create a relay that is suitable for a specific application.

Figure 1 shows the basic design of a miniature single pole power relay. A movable contact terminal is brought together with a stationary contact terminal under pressure from a ‘card’ which is led by the force from armature which is moved by the magnetic field in the coil.

Figure 1: Contact material

An often overlooked detail on the data sheet, the contact material used is central to the performance of the relay. The standard contact material for low-medium power relays is silver nickel (AgNi). It is a harder material than pure silver, and exhibits lower levels of material evaporation. It also has a higher melting point, which helps prevent contact welding at higher currents.

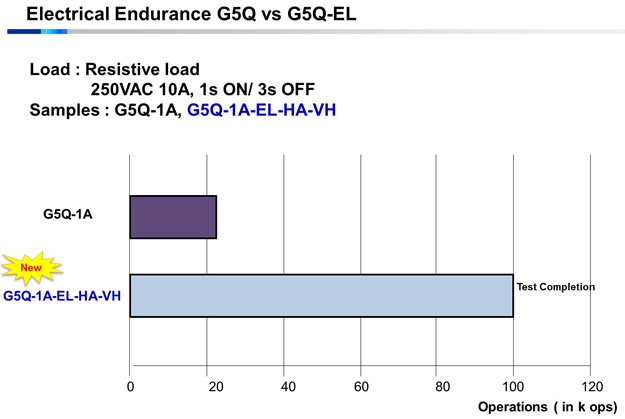

For medium - high power relay and inrush current applications, Silver Tin Indium (AgSnIn) or Silver Tin Oxide (AgSnO2) contacts are normally specified. This material is more brittle and thus breaks apart more easily preventing welding. In the past, relay users have often specified higher than required current ratings on relays to handle the higher inrush currents. Contact materials like AgSnIn make this unnecessary. A relay specified for 1A disconnection can tolerate a 40A inrush current without reducing the number of operating cycles. Figure 2 compares the service life of an AgNi relay to an AgSnIn relay.

Figure 2

A lower cost alternative to AnSnIn is the cheaper AgSnO2. For very high current applications, other materials like Silver Tungsten (AgW) are sometimes used. At the other end of the spectrum for signal relay applications pure silvers or silver nickels are used which has a lower resistance. To increase contact reliability, further gold plated contacts are used. Some of these options are very costly and are only used in exceptional situations.

Contact bounce

Switching of the relay under load causes arcing, which generates significant amounts of heat (tens of thousands of °C). This not only causes the metal on the contact surfaces to melt, pool and migrate with the current, but can also cause melting in the surrounding components. It is arcing that limits the electrical life of a relay to 100,000 operations or so – much less than the mechanical life which can be over 20 million operations. Arcing is also a well-known source of EMI and can lead to the emission of ozone and other pollutants.

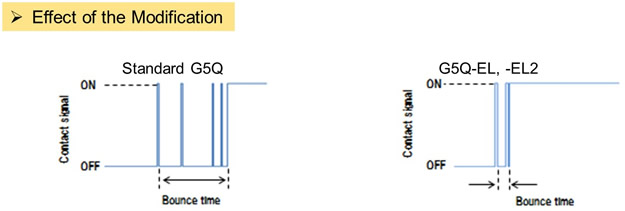

Arcing can be prolonged by contact bounce as the moveable contact touches the stationary contact. One way of reducing bounce time of course is to increase the force from the spring bringing the two contacts together. A drawback here is that the coil power needs to be increased to overcome the spring force, reducing energy efficiency. There are other ways of reducing contact bounce. An important one is to increase the thickness and therefore the stiffness and weight of the terminal.

To maximise relay electrical life, the heat developed during arcing needs to be dissipated, otherwise it will cause melting of not only the contact but also other components like the card which moves the terminal. One way of doing this is to use a dummy terminal which conducts part of the heat away from the card. Figure 3 shows the effect that these modifications have on the bounce time.

Figure 3

Conclusion

The electronics market is continually changing, and new applications keep emerging. Each generation of applications will require new electromechanical switching components.