Reducing power consumption in battery-powered IoT applications

In internet of things (IoT) applications, a long battery lifetime is essential and any technique to extend the useful lifetime would be welcomed, predict Steve Roberts and Maria Alcantara, Recom

While working on the R-78S module reference design, a question arose: could the control pin be used to lower the average power consumption without harming the performance of the end application?

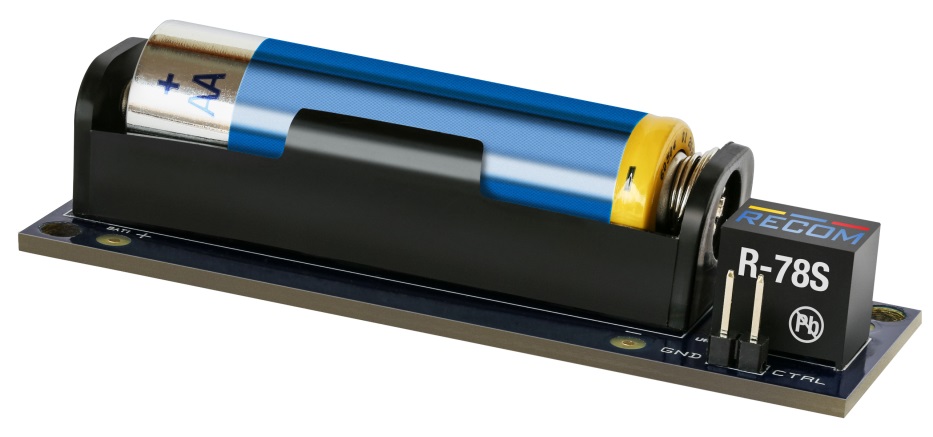

The R-78S module (Figure 1) is a boost converter module that will generate a stable 3.3V output voltage from a single 1.5V battery cell with 93% efficiency. The output voltage remains constant even if the cell voltage drops down to as low as 0.65V, so almost all of the available energy in the cell can be usefully extracted. The R-78S comes in a four-pin package that includes a control pin to shut down the output so that the converter consumes only 7µA from the battery.

Figure 1: R-REF02-78S reference design

Long battery lifetime is essential for the always-on nodes in the IoT, so we decided to try out this idea and built a LoRa test set-up. LoRa radios operate over long distances in open country (more than 20km) and are ideal for harsh industrial environments as well as urban environments, where a 2km range through several buildings is typical.

The test set-up

The test module we used was the Aurel Wireless XTR-8LR100. It was chosen because Aurelis is well-known for low-power solutions, secondly, the LoRa transceiver will run without a separate microcontroller and it has three analogue inputs, making a test set-up transmitting real-life data very simple to implement.

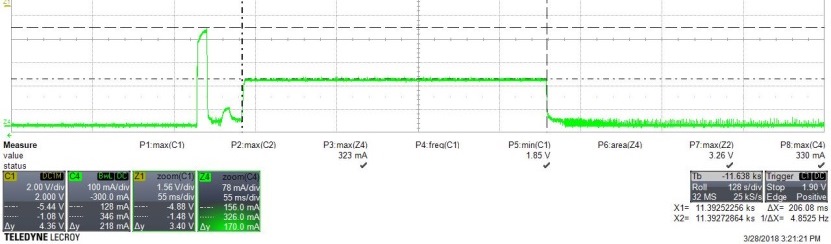

First power consumption was measured with the LoRa module set to be in standby for most of the time and transmitting the three analogue input values every 400 seconds. The current consumption from the 1.5V battery was 339mA peak for 4.6ms, reducing to an average of 121.6mA over the 206ms long transmission cycle (Figure 2).

Figure 2: Current consumption of the LoRa module during the transmit cycle

The expected battery lifetime can be calculated from the following relationship:

Where

C is the battery capacity in mAh (a 15% reduction is included to account for both the self-discharge and the 93% conversion efficiency of the boost converter)

Iwake is the current consumption when active (in mA)

Twake is the active time (in ms)

Fwake is the frequency of wake-ups per hour

Isleep is the current consumption when asleep (in mA)

With a 240mAh 3V CR2032 button cell instead of the AA battery and R-78S converter, the battery lifetime would be only 71 days. In this test set-up, however, the wake up current consumption averages 224.5mA for 211ms with the circuit drawing 160µA when sleeping, mostly due to the no-load power consumption of the R-78S boost converter. An AA alkaline battery has a typical capacity of 2700mAh, so a single cell would be sufficient to run the system for almost a year.

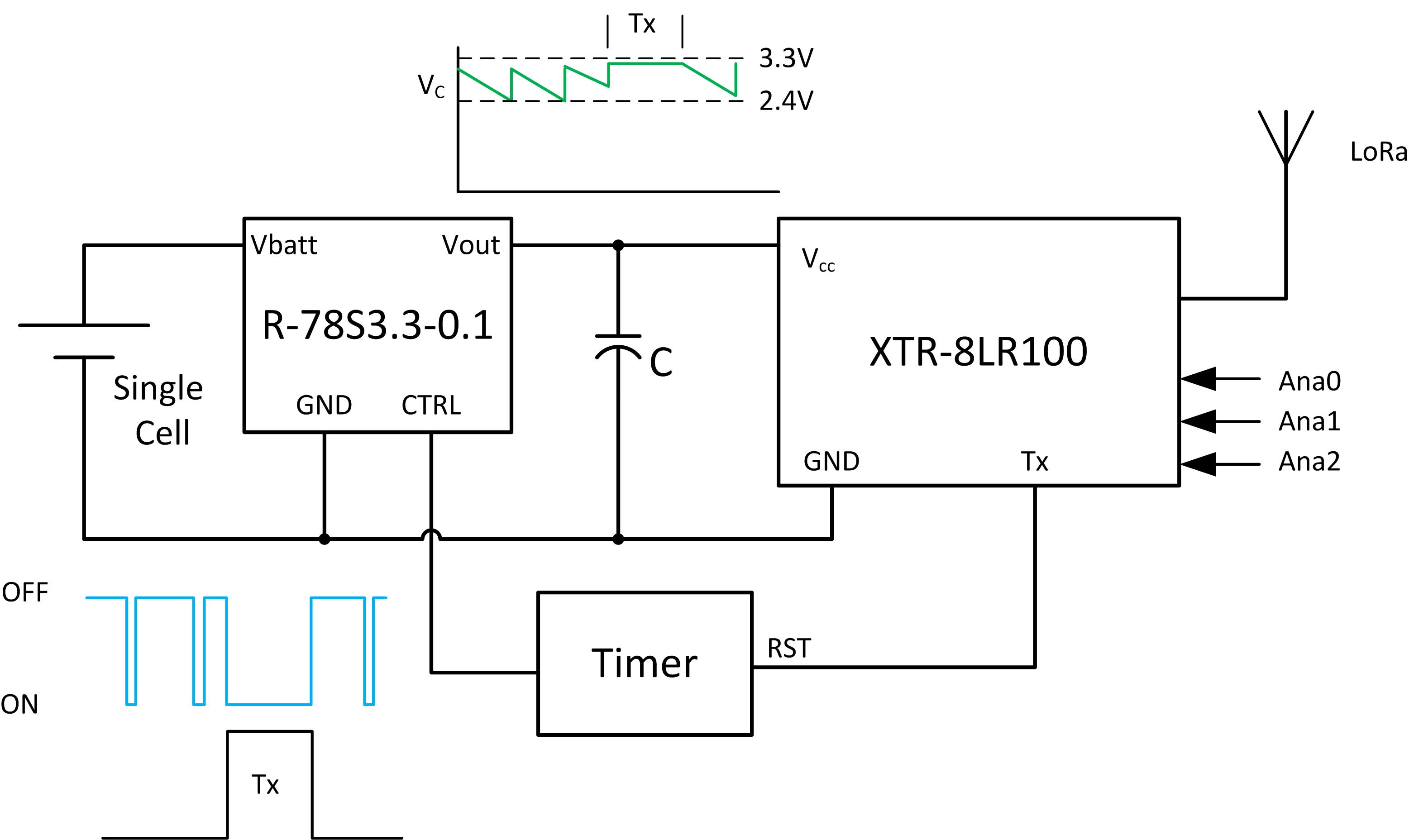

If the sleep current consumption could be reduced to zero, the battery would last more than twice as long, over 800 days. The output of the R-78S boost converter can be disabled with the control pin input, but the LoRa module power supply cannot simply be turned off as it needs the supply voltage to be in the range of 2.4 to 3.6V to run the internal interval timer. One solution would be to add a capacitor to the LoRa module input and turn off the R-78S for most of the time using a low power timer, restarting it every time the capacitor voltage dropped close to 2.4V or the LoRa module started a transmission cycle.

The timer in Figure 3 holds the R-78S off most of the time, starting it up often enough so that the voltage on the hold-up capacitor, C, always stays above 2.4V. The LoRa module has an output that goes low every time it transmits, so this signal can be used to interrupt the timer and ensure that Vcc is kept stable for the duration of high current demand during the transmit cycle (Iwake is a factor of 2,000 higher than Isleep).

Figure 3: Block diagram of a timer circuit to reduce the standby power consumption

Timer operations

The TPL5110 nanopower timer from TI was selected because it has a very low operating consumption and a DRV output that can be directly connected to the control pin of the R-78S boost converter. The Tx output pin if the LoRa module is normally low and goes high as soon as a transmit signal is sent, but the ‘done’ input pin must be pulled low in order to turn on the DRV pin, so a micropower inverter (74LVC1G14) was needed to invert the signal. If ‘done’ is kept high, then the next timing cycle starts after a 50ms delay, meaning the output is always on for 50ms with a time delay to the next pulse set by the programming resistor connected to the ‘delay’ input. If ‘done’ is pulled low, then the timing cycle is interrupted and the output turned on. The TPL5110 runs normally in timer mode and as soon as Tx goes high, the timer is interrupted and the R-78S is kept on for the duration of the LoRa transmission sequence, however long that takes.

A PCB was made, the micropower timer programmed to recharge the 470µF hold-up capacitor every 15 seconds (giving a 15s-to-50ms off/on ratio or a 300:1 reduction in the standby current) and the LoRa module set to transmit every 400 seconds. The battery was plugged in, but it didn’t work as expected.

Capacitance settings

Further investigation revealed a current drawn by the voltage divider inside the R-78S was needed. The internal reference voltage is fixed at 1.2V so the output voltage has to be divided down internally with the ratio of 3.3 to 1.2V or 2.75:1. This resistor chain is permanently connected to the output pin and acts as a discharge path for the hold-up capacitor. A series diode was needed to block the current path to ground. Fortunately, the R-78S is also available with a 3.6V output, designed to allow for the voltage drop across a Schottky diode placed in series with the output.

In the final version, the capacitor could be reduced to 330µF and the capacitor voltage replenished every 15 seconds to keep the supply voltage above a minimum of 2.5V so that the LoRa could transmit every 400 seconds.

The hold-up capacitor could not be safely reduced below 330µF as the LoRa module needs a high start-up current. Increasing the capacitor value and increasing the time delay between recharging pulses meant that the peak capacitor recharging current became higher so that the average current drawn by the circuit remained the same. The best choice was a 330µF capacitor; the peak capacitor recharging current was then 348mA for a period of 2.03ms. This equates to an average sleep current demand of 62µA, or a reduction in the standby current of 62µA/160µA ≈ 40%.

Putting the new sleep current of 62µA into the battery lifetime equation gives a battery lifetime of just over two years – more than double the lifetime without affecting the LoRa radio performance.

A 3V lithium-Ion coin cell has such a low capacity that it is not very useful for high pulsed current IoT loads such as a LoRa WAN. A much better battery lifetime can be achieved by boosting a 1.5V AA cell voltage up to 3.3V.

The current consumption during sleep mode is an important factor in the battery lifetime. If the system supply voltage can be maintained by a capacitor, then substantial reductions in the standby current consumption can be realized if the battery is disconnected for most of the time.

For an even longer battery lifetime, two AA cells could be used in series. Initially, the R-78S boost converter would have been superfluous as the 3V battery output voltage would be sufficient to power the LoRa module directly. However, the discharge curve for a two-cell AA battery shows that the output voltage would fall below the minimum Vcc voltage of 2.4V when only 60% of the battery capacity was used, leaving 2200mAh of the available battery energy unused.

It is also possible to use two AA cells with the R-78S3.6-0.1 boost converter. The maximum input voltage is 3.3V, so two fresh AA cells in series delivering 3.10V would be within the input operating limits. The boost converter keeps the output voltage stable down to an input voltage of 0.65V, for almost 100% of the energy to be extracted from the battery. A double AA cell battery and R-78S would last well over 1,000 days in this application.

Visit Recom at PCIM 2018

Hall 6-304