Powering passive optical LANs

Copper cabling is being replaced by fibre optic-based systems to keep up with networking demands, says Kevin Borders, Alpha Technologies, a member company of the Association for Passive Optical LAN

For decades, the local area network (LAN) has been a cornerstone for enterprise IT architectures. Networks of cascaded aggregation and switching devices tied together by copper cabling have endured a stream of changes – from best-effort access to always-available; from connecting computers to connecting Wi-Fi access points, cameras, and IP devices; and from malicious viruses to a range of security threats that include data theft and espionage. The bandwidth limitations of the copper cabling however has led to the development of a new, fibre optic-based architecture called passive optical LAN (POL).

POL is a derivative of the passive optical networks (PONs) used in fibre-to-the-home architectures that are deployed by telecommunications service providers. The PON is tailored for indoor use by shrinking the optical-to-electrical end device, or optical network termination (ONT), to the size of an AC gang box for easy installation. Other ONT adaptations include the ability to power PoE devices and the addition of advanced Ethernet protocols required for connectivity in a modern enterprise workplace. In all other regards, the POL architecture is consistent with its telecomms cousin.

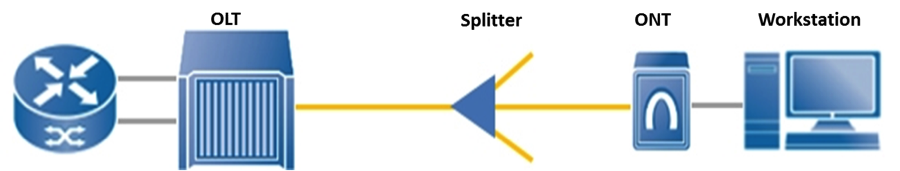

POL uses a common optical line termination (OLT) to connect fibre cables to ONTs at the end points of the LAN network. To minimise cabling costs, passive optical splitters divide the fibers into multiple independent paths for connection to the end devices. The ONTs connect to phones, computers, video monitors, Wi-Fi access points, cameras and smart building end-points (see Figure 1).

Figure 1: A typical POL network

Figure 1: A typical POL network

The POLs change the connection paths, but not the end-points of the LAN, so the same network connections and services are maintained. Desktop computers, phones, Wi-Fi access points, security surveillance, and video conferencing are left intact, but connected via ultra-fast, high bandwidth fibre cables. The elimination of the copper-based LANs removes costly, bandwidth-constrained equipment in the middle of the network, improves security by reducing the number of network points of vulnerability (e.g. equipment access and human management), lowers overall expenses by shrinking the cost and weight of cable, and eliminates the need to replace the cabling when bandwidth demand changes. When end devices change or more bandwidth is needed, the only upgrades required are at the OLT and ONT.

Powering ONTs

The one concern with POL is how to power the ONTs. The conventional method of supplying power locally from an AC outlet is expensive and cumbersome. The cost of providing an AC outlet can be expensive, and even when an existing AC outlet is available, accessibility to the public can result in outages if accidentally unplugged. When battery back up is required, a bulky UPS is needed at each protected ONT. This increases the capital cost, but also creates a recurring operational expense to maintain the batteries.

The local power issues led to the development of remote line power (RLP). The power for the ONT is not provided by a local AC outlet, but from a power supply located in a central site. Power is delivered over conventional copper cables which are hardwired to the ONT. The cables can be installed behind the wall, solving the problem of accidental disconnection.

There are three fundamental electrical requirements for an RLP network. First, it must deliver enough power to energise the ONTs. A typical four-port ONT supplying PoE to downstream devices consumes 60 to 70W. Second, the voltage must be at least -50V DC at the ONT to deliver PoE+ power to downstream devices. Third, the power network must comply with the requirements of the National Electrical Code.

Article 725 of the code defines a type of remote power circuits, known as Class 2 circuits. To ensure safety and fire prevention, these circuits are limited to a maximum power of 100W and maximum voltage of 60V DC. In addition, they must achieve the 100W limit even when the primary protection circuit does not operate correctly. Compliance with Class 2 means the circuits can be deployed over conventional copper cables without requiring conduit or certification by licensed electricians.

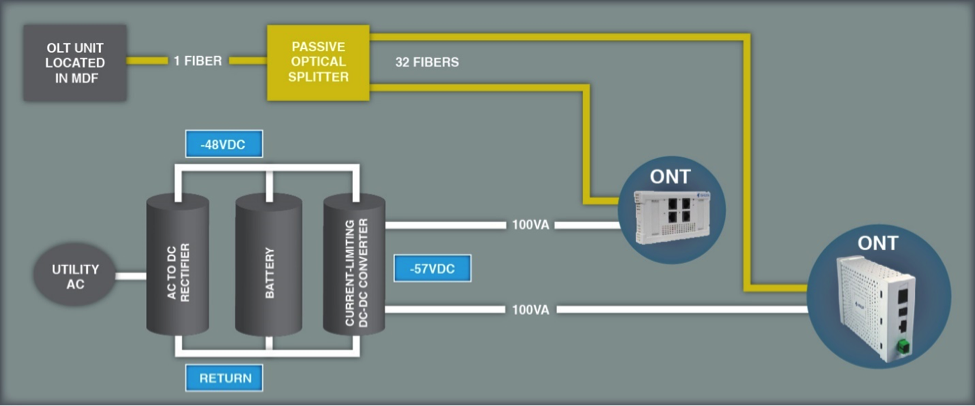

Figure 2: Diagram of the RLP network

Figure 2: Diagram of the RLP network

The source of power for an RLP network is a -48V DC rectifier and a battery plant. Often, this is the same equipment used to power the OLT and the network equipment. To maximise reach, the -48V plant connects to a special DC/DC converter that elevates the voltage to a constant -57V DC output, which connects to the cables.

The DC/DC converters have built-in active current limiting at a maximum of 100W per circuit. The -57V DC voltage level complies with NEC voltage requirement, is greater than the -50V DC requirement for PoE+ at the ONT, and is sufficient to overcome the voltage drop in the copper cables that enables the circuits to reach ONTs at the edge of the network. For example, an 18AWG cable can power ONTs up to 400 feet from the power source. (See Figure 2.)

The design of the RLP architecture varies, according to the layout of the facility, the availability of riser space and space in the intermediate distribution facilities (IDFs), and the number and location of the ONTs.

Architectures for RLP

There are two primary architectures for deploying RLP POL networks. In the distributed RLP architecture, AC power is supplied in the riser to the power equipment located on select floors in the facility. In the centralised RLP architecture, the -48V DC power and battery equipment is consolidated in a central location, often the first floor or basement. Cables carry DC power to the DC/DC converters placed on the floors. In both cases, copper cable is deployed alongside the fibre to each ONT.

Combining fibre and copper is the ultimate solution for LAN deployments. POL is a future-proofed fibre-based LAN; when demands increase, say from one to 10Gbit speeds, the only items to replace are the electronics at the end points (OLT and ONT), leaving the fibre infrastructure intact. RLP lowers the overall cost of installation, improves reliability by offering consolidated battery back up, and ensures compliance with the NEC.