Power engineers struggle to overcome the same old problems

Power management is an increasingly important element of electronics design. Engineers face a variety of power management challenges as portable systems require increased battery life, whilst mains-powered systems need to address power consumption to reduce thermal issues, cut operating costs and to meet the environmental need for lower CO2 emissions. In a recent research project, Napier surveyed the readers of Electronic Specifier to understand their needs and the challenges they had to overcome.

The first thing we found was that a wide range of engineers are required to undertake power electronics design, yet most of them are not specialists: almost two-thirds of the respondents (65%) said that power electronics was either “just one part of my job”, or that they “do little power electronics design”. Despite this, the majority (56%) said that power management products were either critical or very important parts of their system.

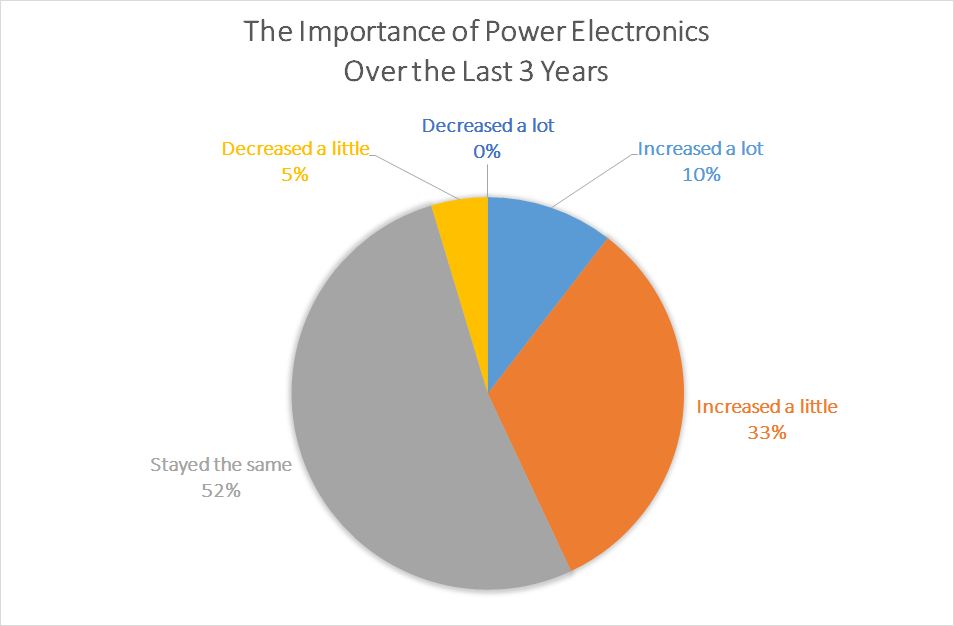

The survey reflected the accepted wisdom that power management is becoming more important: just 5% of the respondents said that the amount of power design they were required to undertake had decreased over the past three years. Interestingly 52% said that the amount of power design they are required to do hasn’t changed, but almost half (43%) of the respondents had been required to do more power design in the last three years, supporting the view that many systems are requiring more power management to allow them to meet their design goals.

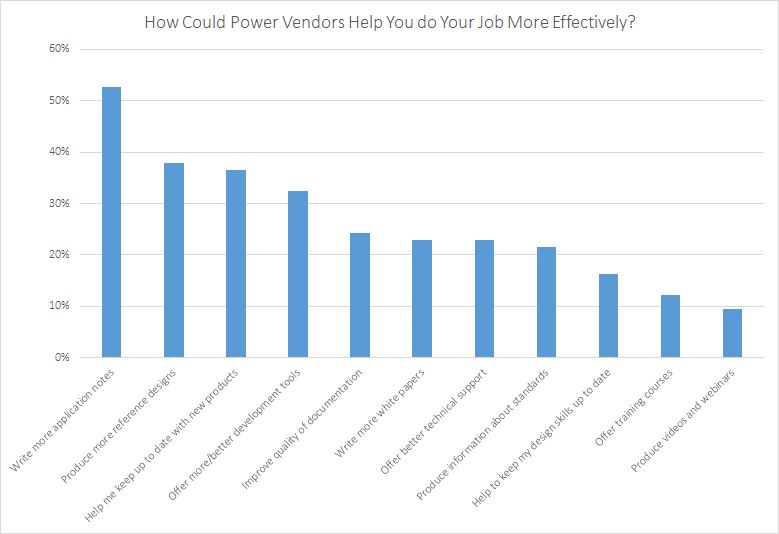

Like many other areas of electronics design, engineers are struggling to keep up with new developments, and are looking to suppliers to help them. The main requirement was for support to make designing-in products quicker and easier: 52% of the respondents asked for more applications notes, whilst 38% wanted more reference designs. Component manufacturers, however, were also criticised for not communicating information about the devices they develop: 36% wanted suppliers to provide more information to keep them up to date with new products.

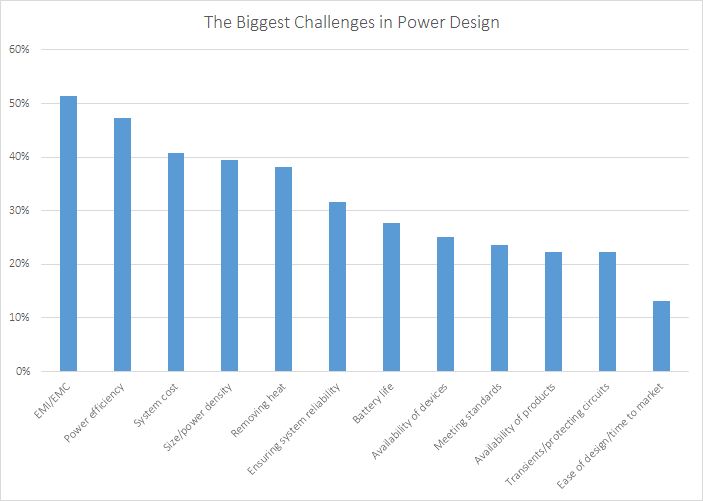

When asked about the problems they faced, engineers highlighted EMI/EMC (51%) and power efficiency (47%) as the two biggest challenges. It’s interesting that these remain obstacles, despite being a focus for both suppliers and system developers for many years. Other key issues included size/power density, removing heat and system cost. It’s interesting that that technical issues such as EMI/EMC, efficiency and power density were rated as bigger challenges than system cost: there is clearly an opportunity to manufacturers to make money by developing solutions that allow designers to overcome these critical technical challenges.

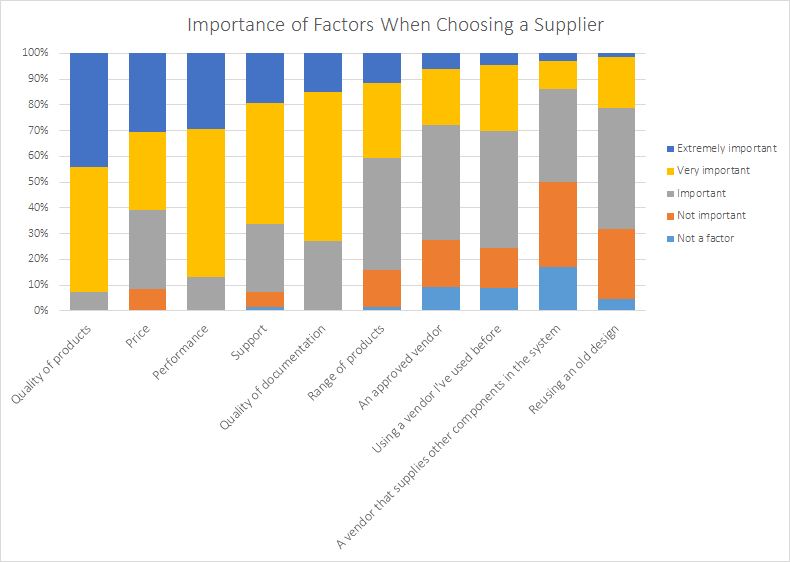

Interestingly the factors that determine vendor selection were slightly different from those used to select analogue products. Whilst quality of products was the main criteria (93% rated it as very or extremely important), price ranked more highly than for analogue products when selecting a vendor, despite the fact that it was only the fourth biggest challenge. Support was seen as marginally more important than good documentation, and interestingly whilst engineers are quite keen on using vendors with whom they are familiar, they are less worried about actually re-using existing designs. This is different when engineers choose analogue products, perhaps because it’s easier to reuse an analogue function, whereas each system will require a unique power chain.

This research shows that power management is becoming an increasingly important element of many systems – although half of engineers haven’t seen an increase in the importance of power design in their jobs. The challenges faced, however, haven’t changed, with EMI/EMC still the biggest problem that designers must overcome. If the lives of engineers is to get easier, power component manufacturers must find ways to make achieving compliance easier, whilst continuing to increase power density and efficiency. If the manufacturers can do this, the fact that cost is much less of a concern means that engineers will readily adopt these innovations.

By Mike Maynard, Managing Director Napier Partnership Limited