Packaging power for the next generation

The concept of hybrid and electric vehicles is far from new, but the challenges in the ascendance of the latest generation require new solutions. By Benjamin Jackson Senior Manager, Automotive Power Switch & Power Module, Product Management & Business Development, with International Rectifier.

Visit any motor show in the last few months and it will very quickly become apparent what the latest trend is electrification. The mass production of hybrid and electric vehicles represents a seismic shift in the motor industry, but it is conceptually nothing new. The origins of the electric car can be traced back to the 1830s, by around the turn of the century in 1900 about 38% of all cars on American roads were electric powered, second only to steam power, and furthermore, the world’s first hybrid car was the Löhner-Porsche Mixte Hybrid which was released in 1901! Given this background it is reasonable to be skeptical about what could be seen as the latest phase of enthusiasm for electric cars.

But given the dramatic increase in fuel costs over the last 20 years and ever more stringent taxes on emissions, the drivetrain of an automobile is being squeezed from both ends; simply put, efficiency must improve and the electrification of the car is an effective means to do this. The challenge for Engineers is daunting, the internal combustion engine has been a cost effective, reliable and high performing solution for over 100 years and it still has life left in it. So for the power electronic solution to succeed it must achieve outstanding reliability, high performance and efficiency at a low price point.

In most (H)EV platforms on the road today there are three main emerging applications for power electronics; battery management, DC-DC conversion and the main inverter motor drive. The main inverter drive is one application which so far has relied on power semiconductor and module technologies which have been adapted from the industrial market where similar power levels and voltages are often seen. However in an effort to reduce cost, size, and weight, improve efficiency and not sacrifice one bit on reliability a new set of silicon and power packaging technologies are needed which are to be developed specifically for automobiles.

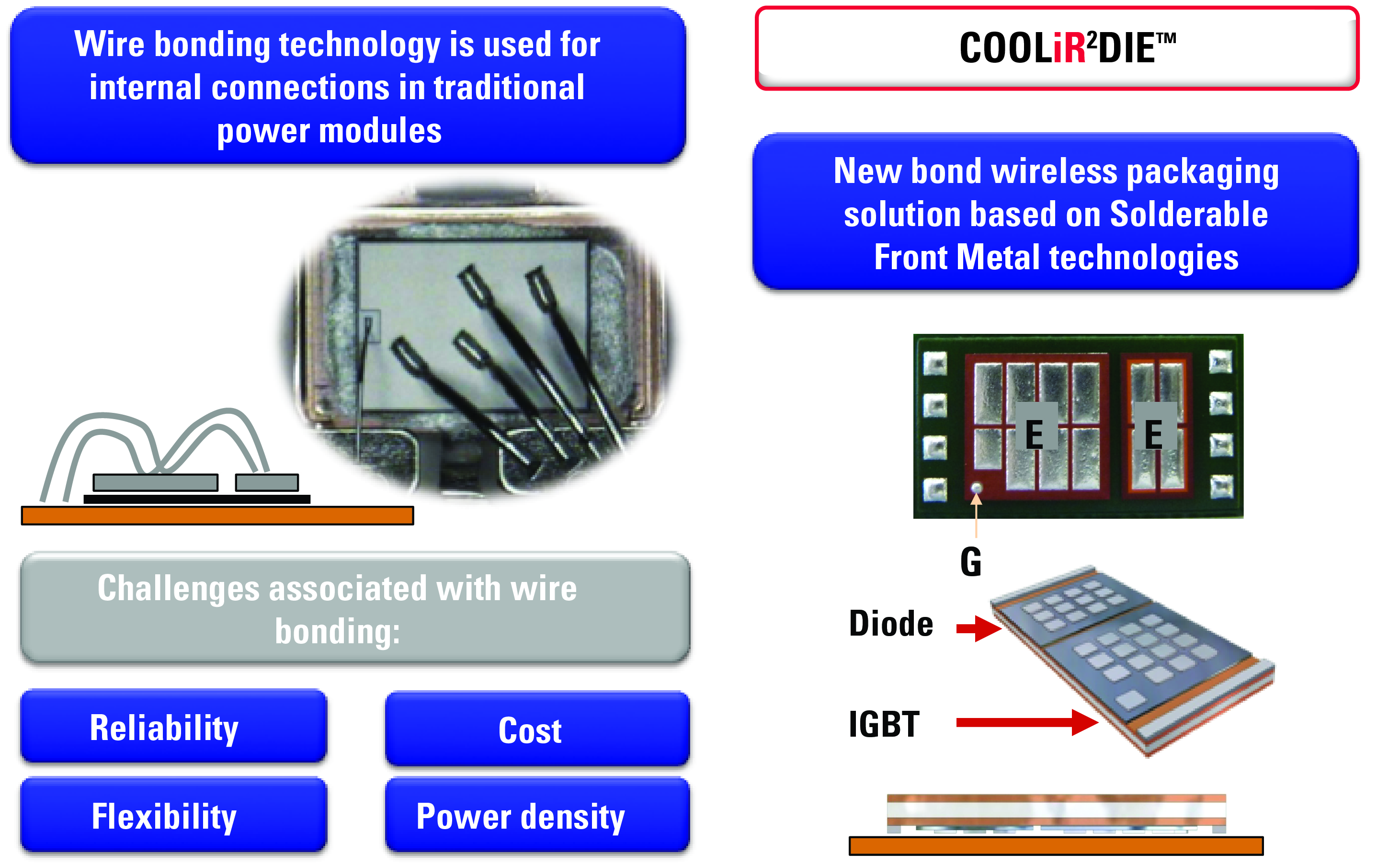

Traditional industrial motor drive modules are generally based on 600 or 1200V IGBTs and DIODEs in a wire bonded package. On the left hand side of Figure 1 an example of wire bonding can be seen, as the name suggest this method relies on the use of small wire bonds, perhaps 20mils (thousandths of an inch) in diameter that are attached directly on top of the silicon and then to a lead frame assembly which makes the final connection to the wider system. Such technology is highly established and considered cost effective.

Figure 1: Comparison of traditional wire bonding and the new CooliR²DIE

However there are several limitations with wire bonding: multiple wires are needed to carry higher currents, therefore more complex and costly assembly processes are needed. When an issue occurs in the assembly it is very hard to rework the module resulting in a particularly expensive yield fall out. Reliability is also the week point of the wire bonds — after thousands of active power cycles the wire bond and its interface to the silicon is all too often the cause of a failure. Finally the wire bonds take up space on top of the semiconductor die and around its edge; this reduces the power density of a given solution and inhibits the ability to cool from the top as well as the bottom side of the device.

To this end Solderabale Front Metal (SFM) technology was developed several years go, which enables direct soldering from the substrate to the top side of the semiconductor. SFM has been successfully used in billions of devices over the last decade and the improvements in reliability over wire bonds are well charted in literature. SFM allows the wire bond to be eliminated and in addition to the improved reliability the manufacturing process of modules can be dramatically simplified with the elimination of the wire bond process step in its entirety and its associated yield loss.

With the need to provide a new power module building block specially tailored to the needs of (H)EV systems the engineers at International Rectifier applied SFM along with concepts similar to those used on the DirectFET package to produce a new device, CooliR²DIE capable of holding die up to 225mm² and targeting power levels above 50kW. The right hand side of Figure 1 shows the CooliR²DIE assembly; a 680V, 175˚C Tj max ultra-thin IGBT and diode along with an SFM finish are mounted on a ceramic carrier. Solder bumps complete the package, the resulting product eliminates the wire bonds but also eliminates the needs for module manufacturers to handle the sawing and placement of die that can be 70µm thin, or even less. Rather than having to buy thin wafers, the manufacturer is supplied with CooliR²DIE parts on Tape and Reel, these parts go through a standard pick and place process and are then reflowed to the substrate; more like populating a PCB with D2Pak devices than building a module with 70µm thin die and wirebonding.

Half bridge variations

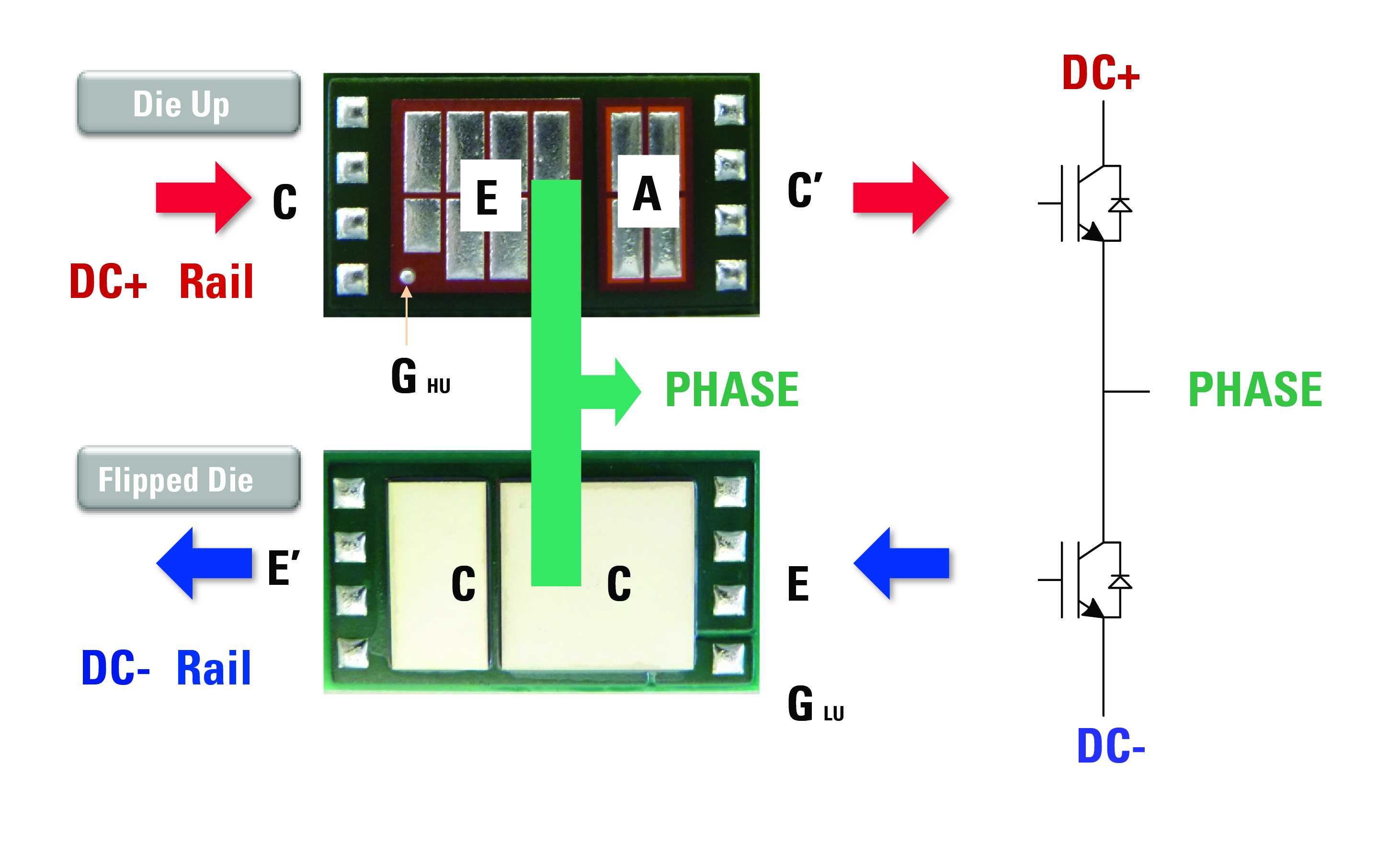

Figure 2: Two different versions of the CooliR²DIE forming a half bridge

A second step enables further system simplification; two variations of the CooliR²DIE give the designer the opportunity to construct a very optimum circuit layout using only a single layer substrate material. Figure 2 shows the two variations — ‘Die Up’ and ‘Flipped Die’. Both are identical in terms of dimensions and electrical performance, the only difference is the orientation of the IGBTs and diodes; in the ‘Die Up’ configuration the collector of the IGBT and the cathode of the diode is connected to the ceramic carrier. This is reversed in the ‘Flipped Die’ configuration. By using the Die Up for the high side switch and the Flipped Die for the low side switch a very compact, low inductance half bridge can be constructed. It has been shown possible to build a module with a loop inductance of less than 12nH using such a configuration; well below that of standard wire bonded modules on the market today.

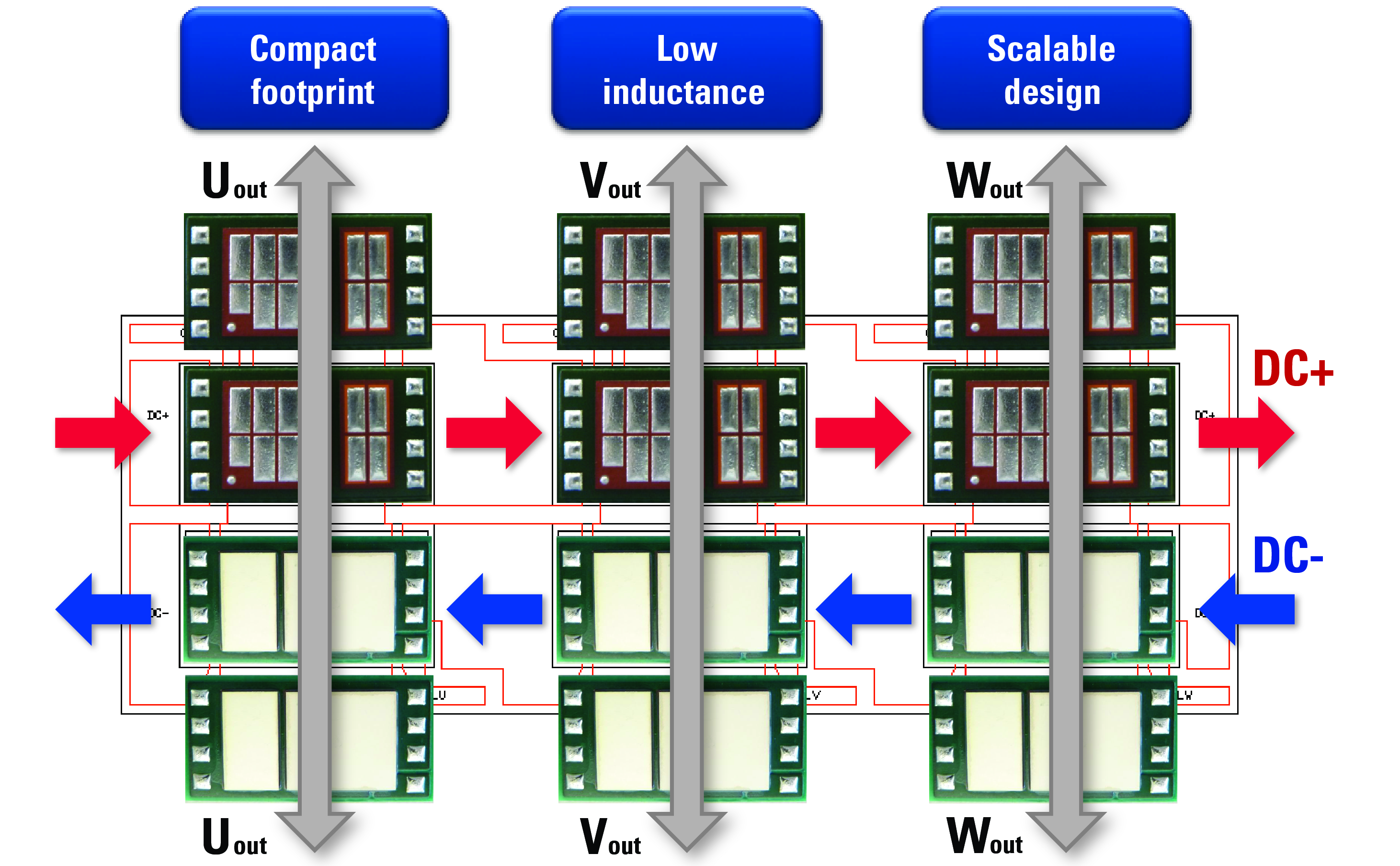

Furthermore the construction of the CooliR²DIE means that the solder bumps on either end of the carrier are in fact connected to each other (see Figure 2, terminals C/C’ and E/E’). This means when constructing a full three phase inverter (as shown in Figure 3) the CooliR²DIE carrier itself can act as part of the DC bus bar, thereby eliminating the need for multiple layer boards or complex interconnects. If a scalable design is needed to address a wide variety of platforms devices can be placed in parallel.

Figure 3: Using the CooliR²DIE to form part of the DC bus bar connections in a three phase inverter

By moving from a wire bonded module construction to one using direct solder connections to the die much more compact and electrically efficient systems can be constructed, furthermore the manufacturing simplification and cost reduction is clear — the cumbersome wire bonding step can be removed altogether. Moreover the impact on reliability is dramatic; the number of active power cycles creating a temperature delta on the junction of the semiconductor is one such metric of measuring the reliability of power modules. Figures for the reliability of wire bonded modules vary, but it is not uncommon for a traditional module to achieve up to 100k cycles with a Tj of 85˚C. In prototype testing the CooliR²DIE has achieved over 950k cycles.

For electrification of the automobile to be a success it will require political will, which the world now has. Financial motivation is also a key driver and increasingly such vehicles are coming more affordable through tax incentives, lower capital cost as volumes ramp and a growing charging structure. But ultimately the performance of the car must not be compromised, the internal combustion engine has set a very high benchmark and electric and hybrid vehicles must rise above this to succeed, optimised power electronics meeting the specific needs of the automotive industry will be a vital driver for electrification of the car to be a success.