Can an extended warranty ever equal reliability?

Increasingly manufacturers are offering an extended warranty with a new EMC or EMP filter. That doesn’t make it more reliable or long-lasting, argues Paul Currie

Extended warranties are very commonly offered alongside commercial product sales. How many times have you been asked if you would like to purchase an extended warranty for an additional fee? Quite simply, this additional fee is the manufacturer’s mechanism for offsetting their additional risk. The lower the fee, the bigger the risk the manufacturer is willing to take.

There are a number of reasons why a manufacturer may offer an extended warranty free of charge. Most commonly it is because the risk has already been built into the unit price. It is also used as a selling feature or to infer a message of reliability.

EMC and EMP filter manufacturers are often asked by installers or end-users “Do you offer an extended warranty?” Invariably the questions underlying this are around the lifetime of the filter, when will it need to be replace or how reliable it is.

The manufacturer can enter a dialogue regarding the design and manufacturing quality of the filter, providing technical and quality documents in support of the claims. Alternatively, the manufacturer may wish to convey an established track record and minimal failure rates. Again, this requires significant effort and supporting information, which must be carefully researched and calculated. The quickest and simplest way may be to offer the extended warranty, but what does that mean?

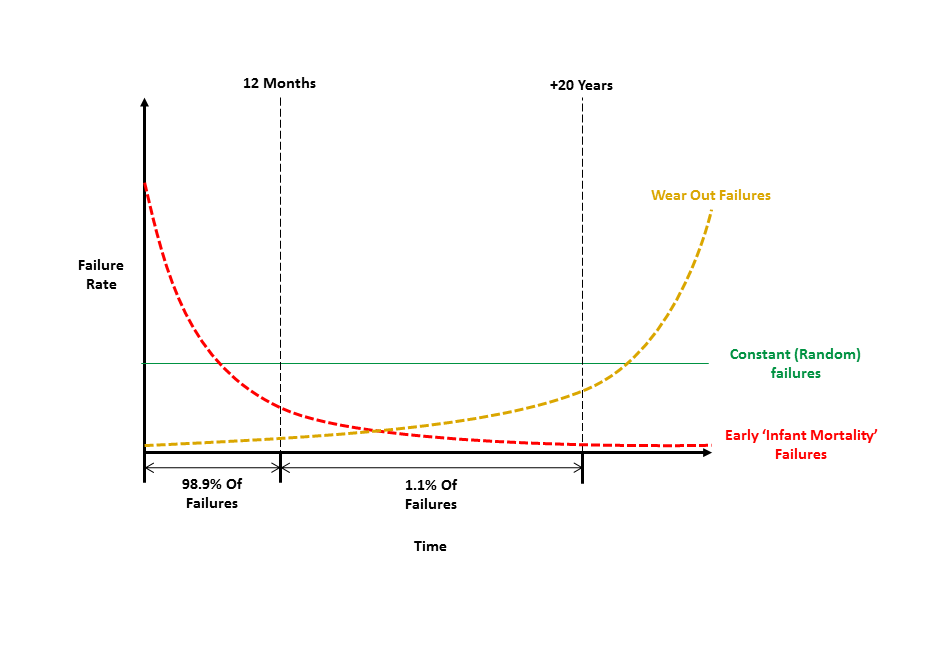

The bathtub graph of failure rates over time

What could go wrong

The over-arching question must be: “Does the fact that the manufacturer is willing to repair the faulty filter for a longer period of time itself make the filter any more reliable?” The answer is categorically “No”. The filter will undoubtedly have been designed and manufactured following the same processes, whether it is to carry a one-, two-, five-year or other period, warranty. An extended warranty does not make the filter more reliable, but does it offer additional security.

The inaccessibility of filters

Why filters fail

However tightly manufacturing processes are designed, employed and monitored, there is the possibility of a manufacturing defect, however remote. In the case of any filter failure as a result of such a defect, this is almost always identified prior to or during installation.

On occasions, there can be damage during shipping or transit. Again, any damage caused through shipment is almost certainly identified at inspection before, or during, installation.

If a filter has been incorrectly specified, it will not operate as intended. This will be identified during installation.

In some cases filters may be required to be verified against certain published specifications or standards, HEMP filters to MIL-STD-188-125 for example. If the filter were not to pass such a verification test, this would again be identified prior to sign-off on site.

Analysis of EMC/EMP filter failures and returns shows that these components may be considered much like a muscle within the human body prior to exercise, i.e they are much more likely to be strained during the initial period following commencement of any exercise than at any time during the exercise that follows.

It has often been said that if the filter works first time, it will typically continue working, and statistics support this theory. Analysis demonstrates unequivocally that 98.9% of filter returns occurred within the first 12 months of manufacture.

In the event of a failure, and assuming that the filter has failed in a mode which attributes the fault to the filter, the filter has to be repaired or replaced.

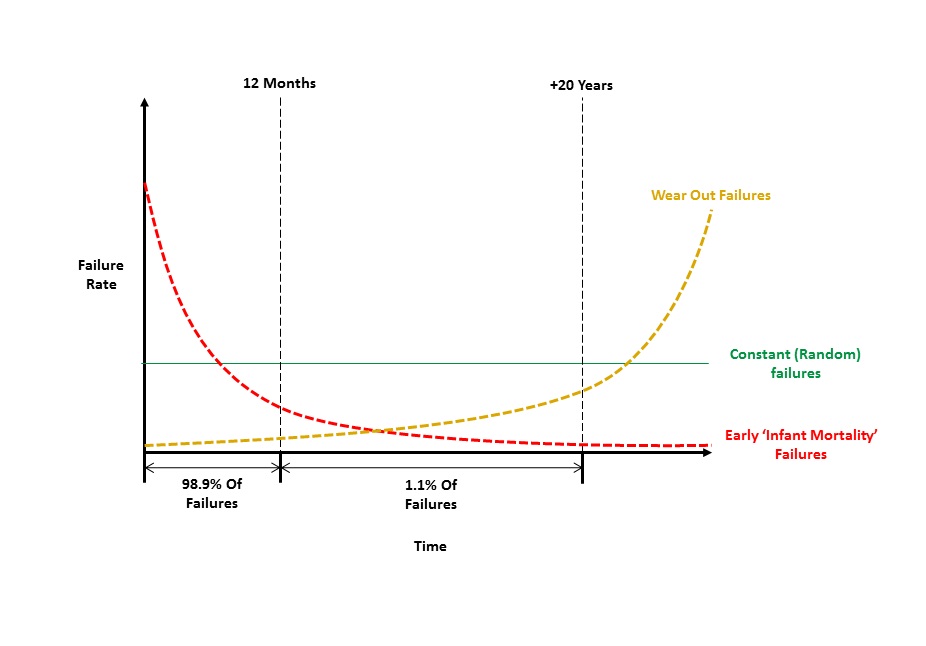

The filter is most likely to fail at the time of installation or the acceptance test. In this instance, remedial steps must commence with disconnection of the incoming power supplies to the filter, which may require a site-approved individual independent of the installation team personnel. Once supplies are disconnected, removal of the filter covers, disconnection of the filter connections and dismounting of the filter will be required. The accessibility of the installation, along with size and weight of the filter, will determine how simple or involved this process is. However, such a process is going to involve at least two individuals and may call for additional personnel, specialist skills such as welding, specialist certifications such as working at height or rope access, and specialist equipment such as crawling boards, hoists or trolleys.

All of this remedial work is required before transporting the filter back to the manufacturer or installation of a new one can be considered. It is impossible to put a generic cost on these actions, but in terms of both finance and time, even in the simplest of installations, these costs will not be insignificant.

In this situation the filter will be repaired or replaced by the manufacturer regardless of any standard or extended warranty. In real terms, however, the manufacturer’s cost to repair the filter would be a small fraction of the onsite remedial costs incurred.

Filter installation and test

Failure within the warranty period

If the filter fails during the warranty period - a situation which is far less common - the remedial steps that are required to remedy the failure are identical to those where the filter fails during installation. The costs will typically increase in terms both of finance and time, depending upon the maintenance contract in place at the time.

In real terms, for a filter not covered by any warranty, the manufacturer’s repair cost would be the same as when the filter fails at the time of installation but the repair cost is a smaller fraction of the onsite remedial costs incurred. Therefore, regardless of warranty, it is undoubtedly better that the filter works, continues to work and does not fail.

A third scenario is one in which the site has been operational for a time, the installer has left the site and the manufacturer’s standard warranty has elapsed. Analysis shows that failures attributable to a filter fault are least likely in these circumstances (only 1.1% of all returns) and so least common in reality.

The extended warranty covers the manufacturer’s repair cost for the filter, the same cost as in each of the earlier scenarios, but this repair cost is only ever a small fraction of the overall cost of remedial work. In this case, the time elapsed since installation often means that the user’s responsible site personnel and the installer’s personnel have changed, documentation has been archived and attention has migrated to newer or current projects.

This means that, in the event of a filter failure, remedial actions are likely to be a much more protracted and involved process and, in turn, the costs and impact of remedial work are even greater.

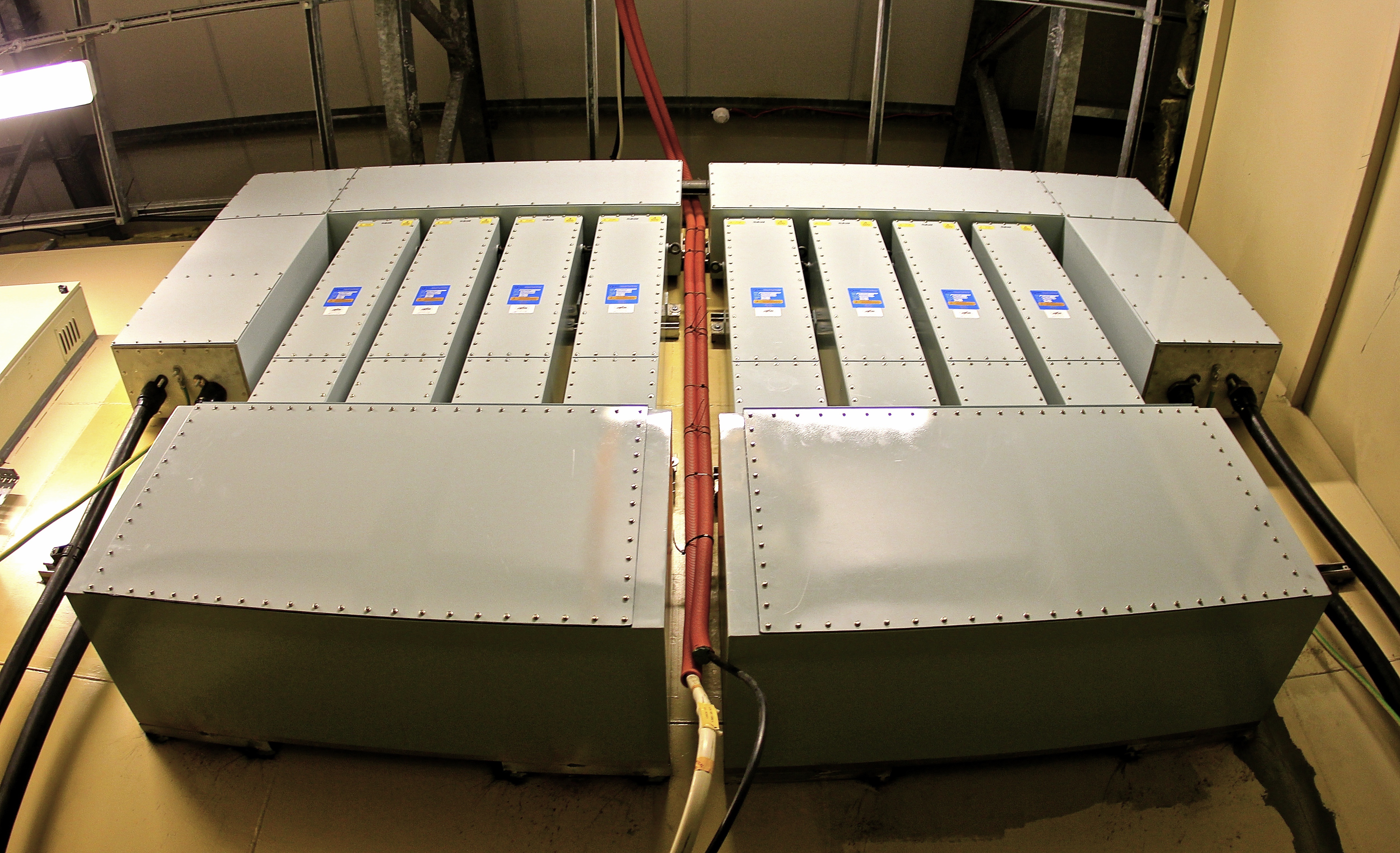

Installation via rope access

The impact of remedial work

As an illustration of the impact and costs of remedial work, let me provide a personal example. Recently, my car was hit by another vehicle whilst I was stationary. Fortunately, all parties were unhurt, but whilst my car was driveable, it required remedial repair work. This was all covered by the other party’s insurance.

It still entailed several phone calls to insurers and the repair centre, followed by a visit to the repair centre to estimate the damage and the work required. Once the repair work was agreed and booked in, I returned, dropped off my car and picked up a courtesy vehicle.

Some days later, on the morning I was due to collect the repaired car, I was informed that a part had not arrived from the supplier. There followed further calls regarding the courtesy vehicle, rearranging of appointments and clearing a further day for collection.

In this instance, the inconvenience and logistics of remedial repairs were my burden.

An extended warranty provides cover for only a fraction of any remedial work costs and impact that may be incurred and in a scenario where filter failures are least likely.

An analogy would be a new display car or classic car. The pristine vehicle is loaded onto a transporter, ferried via congested roads to the showroom, unloaded and then manoeuvred into the showroom. At that point would we consider taking out upgraded bodywork insurance?

Of course, there is always the chance that, when manoeuvring the car in the showroom, the bodywork may get damaged, but, where speed is minimal, there are no other vehicles involved and movement is infrequent, it would be mitigating an already tiny risk. The greatest moments of potential risk – loading, transportation and unloading – have already passed.

The question is, is it more important for a site to continue operation uninterrupted, or is it more important to mitigate a minimal percentage of costs in the event there is a failure?

About the author:

Paul Currie is sales and marketing director of the EMC, EMP and TEMPEST filter designer and manufacturer, MPE of Liverpool