A new platform for precision power measurement

In rapidly evolving industry sectors like renewable energy, electric vehicles and energy-efficient technologies, the need for reliability in testing to enhance safety, efficiency and performance has never been greater, says Anoop Gangadharan, Yokogawa Europe

In the area of power transmission and distribution, for example, new developments such as renewable energy stations or energy-positive buildings and infrastructures, mean that electricity no longer has a uni-directional flow from the power station to the consumer. With a multitude of renewable and non-renewable power stations feeding the grid, engineers in charge of ensuring a balanced grid need robust testing and accurate measurements to reduce the impact of noise, distortions and harmonics from multiple sources. Power generation stations and large consumers also need to evaluate the effects of their power outputs and usage levels on the grid and on other users.

Harmonic measurements

In addition, pure sine-wave PWM signals are becoming less common in many applications, so these high-accuracy measuring instruments also need to include the ability to carry out high-frequency measurements. With mean voltages increasingly differing greatly from the fundamental voltage waveform, harmonic measurements are needed to establish the values of derived measurements such as active power. Similarly, addressing the challenges of measuring parameters such as energy efficiency, harmonic content and power factor will require both progressively greater accuracy and consistency in measurement over the specified ranges and conditions.

Similarly, the use of brushless DC motors and pulse width modulated (PWM) waveforms demands the simultaneous measurement of normal values with harmonics for overmodulation analysis of PWM waveforms and the high-speed measurement of power fluctuations.

Addressing the challenges

These challenges can be addressed by the Yokogawa WT5000 (Figure.1), This is the first of a new generation of precision power analysers that offers headline-grabbing measurement accuracy of 0.03%, combined with stability and noise immunity. In addition, it is configurable, with plug-in modules for flexibility and options to meet specific applications.

Figure 1: Yokogawa’s WT5000 precision power analyser

Figure 1: Yokogawa’s WT5000 precision power analyser

There are seven built-in slots for user-swappable power input modules and diverse mainframe options to enable users to expand or reconfigure the power analyser as the applications and their requirements change (Figure 2). In addition to measurements on power parameters, the torque and frequency from four separate motors can be measured.

Other key features include the ability to use 5.0 or 30A input modules in conjunction with the split-screen touch display to compare multichannel measurements. Measurements can be carried out under highly fluctuating input and/or load conditions with an autoranging integration function and automatic data update rates. Additionally, custom measurements add flexibility in evaluations, with user-defined triggers and computations as well as functions such as dual-motor evaluation. The WT5000 also performs harmonic measurements including comparisons of two simultaneous measurements up to the 500th order.

Figure 2: User-swappable power input modules and diverse mainframe options configure and expand the power analyser as requirements change

A full touchscreen interface, supported by hardware hot keys and powerful software for remote measurements, make connecting configuring and measuring simple, says the company.

While a single seven-channel unit may suffice for many applications, it is also possible to connect up to four WT5000 units for synchronised measurements for more demanding applications. This allows up to 28 power channels and 16 sets of motor torque and speed to be measured simultaneously.

Target applications

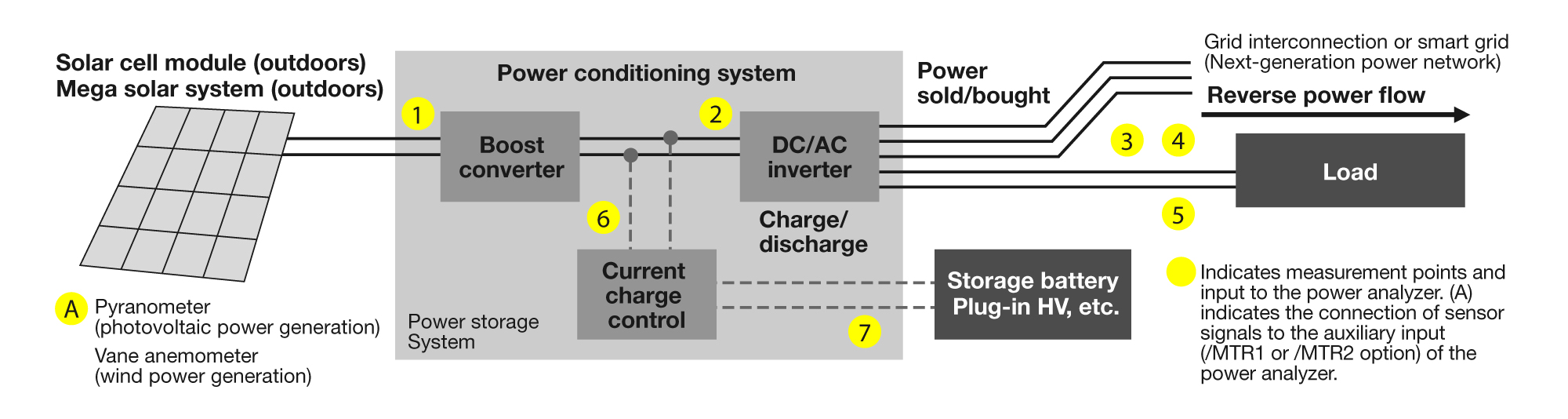

One target application is renewable energy systems. Energy, generated by photovoltaic (PV) cell modules and wind turbines, is converted from DC to AC by a power conditioning system (PCS). Minimising losses in these conversion operations improves the efficiency in the overall system. This typically requires high-precision measurements from six AC phases for wind power generation, and three DC and three AC phases for PV generation. Harmonic evaluations of inverter signals are also needed to account for superimpositions from switching circuits.

It is often necessary to measure the amount of power sold and/or bought in grid interconnection and in battery charge/discharge modes, as well as the instantaneous peak power in maximum power point tracking (MPPT) control of PV power generation. (MPPT is the algorithm for extracting maximum available power from a PV module.)

Advantages of the WT5000 are derived from its multiple channels and wide input range. It can easily evaluate PCS, or power conditioner, efficiency using its seven input channels for simultaneous measurements from the inputs and outputs of the boost converter, inverter, and storage battery. It also enables the integration of current, apparent power and reactive power, as well as the effective power integration in sold/bought power and charge/discharge modes (see Figure 3).

Figure 3: Schematic of a renewable energy system

Figure 3: Schematic of a renewable energy system

Another application is in the automotive sector, in powertrain tests. From R&D to manufacturing and compliance testing, measurements on powertrains in electric vehicles not only require progressively greater accuracies but also consistency in measurement over the specified ranges and conditions.

Key requirements here are DC and multi-phase AC measurements from the battery, inverter and motor, as well as mechanical motor characteristics such as torque, rotation speed and direction. In addition to harmonic evaluations of inverter signals is also important to account for superimpositions from switching circuits. In this context, the seven modular input elements of the power analyset, make it easy to evaluate total power and efficiency, while its ability to evaluate multiple motors on a single unit, allows the testing of two sets of torque and A/B/Z phases or four sets of torque and rotation speed.

Transformer testing

In the power generation and distribution industries, the power supply company and transformer manufacturers are particularly concerned about the economic effect of transformer losses. Hence the accuracy of the measurement system becomes especially important.

Key requirements are to accurately measure voltages and currents in a three-phase transformer, and to evaluate losses under no-load conditions where the phase difference between voltage and current is close to 90°, and the power factor is close to zero. It is also necessary to measure both the RMS value and the average value.

The WT5000 offers the advantages of high precision measurement and angular accuracy, allowing it to accurately measure power values under extremely low power factor conditions, meeting the test requirements of transformers under no-load and load conditions. The transformer no-load loss can be corrected according to the IEC60076 standard.

In conclusion, says Yokogawa, the WT5000 precision power analyser offers an unmatched 0.03% accuracy and modular architecture, helping engineers to innovate their power testing and analysis with precision and flexibility. The instrument can address design challenges in energy-efficient devices as varied and wide ranging as those for plug-in hybrid/electric vehicles or renewable energy technologies. It helps engineers to solve design challenges, improve productivity and ensure quality through reliable power measurements, adds the company.

The accuracy and precision levels are backed up by tests carried out at the company’s European standards laboratory at its European headquarters in the Netherlands. This facility is the only industrial (i.e. non-government or national) organisation in Europe to offer traceable power calibration, to national and international standards, at frequencies up to 100kHz. This is a requirement for higher harmonic measurements specified in quality standards such as ISO 9000.