The wirewound resistor - alive and kicking

The wirewound resistor – alive and kicking, by Phil Ebbert, VP Engineering, Riedon. As with every other type of component, the techniques for fabricating resistors have changed over the years as new technology and materials emerge.

In particular, resistive films have been increasingly adopted to make resistors smaller, cheaper and easier to mass manufacture. But film resistors are not ubiquitous, and the traditional wirewound resistor manufacturing process still manages to stay in the market, filling specialised roles.

Manufacturing pros and cons

Although alternative manufacturing techniques have taken a large share of the market, they still have drawbacks. Both carbon film and thick film resistors are produced from conductive inks. While this technique allows the mass production of low cost components, it also can bring lower electrical specifications, which include weaker pulse handling, a maximum initial tolerance of 0.1%, and less long term stability. Film resistors are also less stable in changing temperatures. Typically these resistors have a Temperature Coefficient of Resistance (TCR) of around 50 to 100ppm/°C. They are also more susceptible to current noise.

Another traditional technique to manufacture resistors is through carbon composition. This technique binds a conductive material (carbon powder) and an insulator (normally ceramic) in a resin. The value of the resistor is achieved by varying the proportions of the conductive and insulating materials. These resistors usually have a minimum tolerance of ±5%, and also are vulnerable to changing temperatures, with a normal TCR of 1000ppm/°C. As with film resistors, they suffer from high current noise and poor long term stability.

Electrically, metal film resistors offer better specifications, with tolerances achievable as low as 0.01%, typical TCR between 10 and 200ppm/°C and stability from 200 to 600ppm/yr. Although they offer better specifications than carbon composite, thick film and carbon film resistors, they still cannot match wirewound construction.

Superior electrical characteristics ensure that there are still many roles for wirewound resistors, which have a better ability to handle pulses and transients. Wirewound resistors are also able to dissipate large amounts of power (up to 2.5kW for some examples), they are very precise, with initial tolerances possible down to 0.005%, and they are very stable (15 to 50ppm/yr). Wirewound resistors also offer a very low level of current noise, often as low as -38dB.

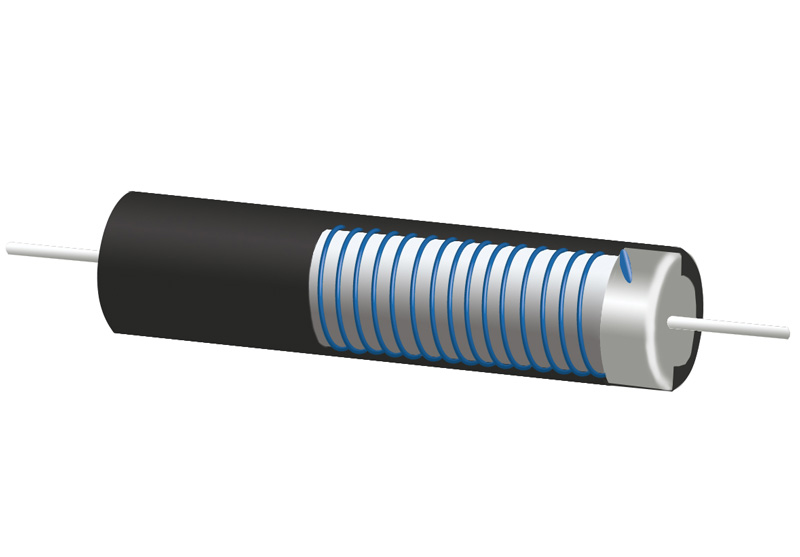

The method of constructing wirewound resistors has remained constant over a long period. The resistive element is a wire, which is wound around an insulating core, normally a ceramic. The resistive wire is welded to metal end caps, which have been pressed onto the insulating core. The assembly is then encapsulated to protect it from environmental damage. The devices are easy to customise, giving users more flexibility when specifying the resistors, even for low quantities.

Figure 1: The fundamental construction of a wirewound resistor has changed little over time.

That’s not to say the wirewound fabrication process has been unchanged - it has also gone through many improvements over the period of its existence. Advancements in material science alone have made several improvements to the resistor’s specifications, including allowing the manufacture of resistors with lower tolerances, and tighter control over variations in temperature, with TCR down to 1ppm/°C.

Each resistor’s resistance value is determined by the calculation ρ.l/a, where ρ is the resistivity of the material, l is the length of the wire, and a is the cross-sectional area. The choice of wire material can make a great difference to the length of wire required. For example, a copper wire with a small cross-sectional area that is 30m long will have a resistance of only a few ohms, while wire made from a material with a higher resistivity, suck as nickel-chrome with a similar diameter, may have a resistance of a few thousand ohms.

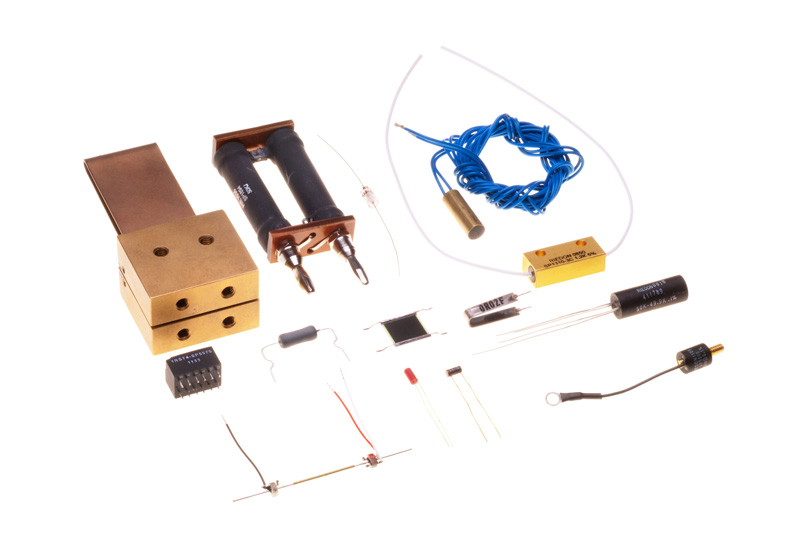

Figure 2: Easy customisation is one of the major advantages of wirewound resistor technology, as shown in these examples from Riedon.

This ability to choose the resistive wire, along with the simple resistance calculation, explains why wirewound resistors are so flexible. If a resistor is specified that needs a very precise tolerance, a longer resistance wire is usually chosen, as it will offer a greater trimming accuracy during manufacture.

Stability under temperature differences

The wide choice of resistive materials also offers another benefit - the ability to tailor the temperature characteristics of the resistor, which is very important for many specifiers. Different materials have different TCRs, and the ability to choose the required resistance and TCR by choosing the resistive material makes this much easier. For example, RO-800 alloy normally has a TCR of between 5 and 10ppm/°C, nickel has 700ppm/°C, and copper 3,900ppm/°C.

These material traits make wirewound resistors very flexible, and able to perform multiple functions. They can even be manufactured to have a high TCR, which opens up further applications, such as temperature sensing or compensation.

One benefit that allows wirewound resistors to stand apart is their ability to operate over a very wide temperature range. A good example of this trait is seen in Riedon’s UT range of axial resistors. These devices can operate reliably in a temperature range from -55°C to 275°C, and at even higher temperatures when derated. This ability in itself makes wirewound resistors uniquely suited to many applications, such as the aerospace and fire suppression industries.

Wirewound resistors are also ideal for applications where devices are required to handle high power, or to dissipate energy. This ability is also linked to the properties chosen when manufacturing the device. In these applications, the mass of the resistor is key - the larger the mass of the resistor, the more power it can handle or dissipate. The greater choice of materials available to construct the resistive element means that wirewound resistors can be manufactured to provide a larger mass.

Pulse handling

One of the most popular applications for wirewound resistors is pulse handling. Some applications, such as medical defibrillators, are required to dissipate a large current pulse in a short period of time. This type of function generally puts electronic components under a great deal of stress. In practical circuits, engineers specifically design in a resistor that can absorb the current spike of a typical surge. Another area where wirewound resistors are specifically used to absorb high currents is in metering modules in a solid-state metre. These modules have occasionally to deal with large voltage surges from the power grid. When this event happens, a Metal Oxide Varistor (MOC) clamps, diverting the power through a resistor, which dissipates the energy, protecting the equipment. There are many causes of these surges, both natural (lightning strikes) and manmade (inductive motor loads). The Riedon UT resistor series, mentioned earlier in this article, are often used in this type of application as they can resist surges of up to 1,000 Joules. The range has resistance values from 0.02Ω to 260kΩ at tolerances down to ±0.01% and a typical TCR of ±20ppm/°C.

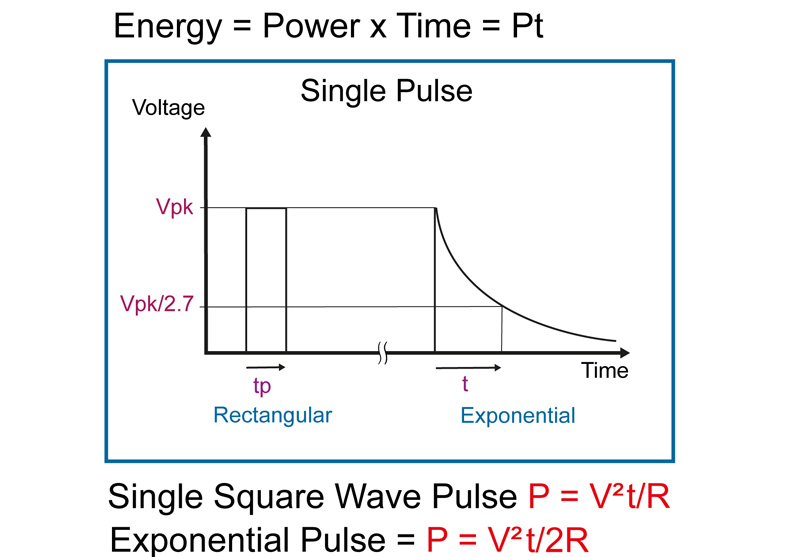

Specifying resistors for these applications is often not as simple as it initially seems. The pulse handling requirements differ, depending on the application. Inrush current applications need different capabilities than circuits used for transient suppression. It is difficult to get all the data required from the usual sources, like datasheets. For instance, for longer pulses of up to five seconds, the standard for specification is to withstand five times the rated power. In practical terms, a 5W resistor must handle a 25W pulse for the whole five seconds, regardless of the packaging type.

Figure 3: Pulse shape, repetition rate and duration all need to be understood in order to calculate the required energy handling capabilities.

In the case of a short pulse, many more details are needed to select the correct component. The mass of the wire decides the power rating, but that is then reliant on both the resistance value as well as the type of package. The package has an effect on the rating by both size and the type of package (axial or surface mount). For the actual pulse, the power delivered depends on whether it is repeated, and also its shape.

Each application and area has its own requirements. For example, if we look at current sensing, two different applications may require completely different types of component, despite being used for the same function. A resistor for a handheld application must have a small footprint, while for a current sensing resistor in an industrial application, the main characteristic may be current handling or precision. Wirewound resistors can easily fulfill both applications.

If accuracy is the main requirement in a current sensing application, four-terminal components can keep the main circuit and the sensing circuit separate for better accuracy. These resistors can offer a range of resistances from 0.01Ω to 1kΩ, at tolerances as low as 0.005%, while handling 25A.

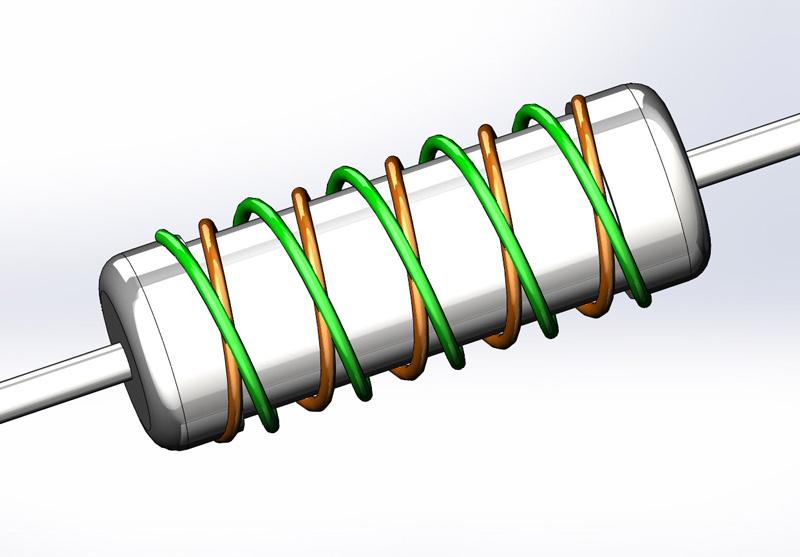

Of course, no technology is perfect and there are some downsides to wirewound construction. The one disadvantage that is most often mentioned is self-inductance, which could be a problem, particularly at higher frequencies. Manufacturers of wirewound resistors get around this by using bifilar winding, which wraps the wire so that it creates an opposing field that cancels out the initial inductance. This technique reduces the inductance, typically by around 90%, leaving only the inductance created by terminations and leads.

Figure 4: Non-inductive winding can produce wirewound resistors with minimal self-inductance.

Conclusion

Wirewound resistors may seem like old technology, but they offer many advantages that negate the downsides of other resistor technologies. The flexibility of the technology means that rather than being purely off-the-shelf components, they can be tailored for each application, allowing designers to determine the device’s characteristics with very few trade-offs. This makes the technology especially relevant for applications that cannot be filled by mass produced cheaper technology.