Laser bar's brilliance suits fibre-optic coupling

The SPL BF98-40-5 laser bar from Osram Opto Semiconductors combines power and beam quality, reducing the complexity of coupling light into fibres. Thanks to its high brilliance, diode or fibre laser systems for material processing can be made simpler and more cost-effective. Even at its maximum output of more than 60W, the component has an impressively long life.

For its SPL BF98-40-5 laser bar, Osram has optimised chip design in terms of beam quality, resulting in a laser with a wavelength of 976nm, a brilliance of 3W/mm and one mrad divergence angle at an optical output of 44W. The SPL BF98-40-5 laser bar is 5mm wide and consists of five emitters, each 100μm wide and each with a cavity length of 4mm.

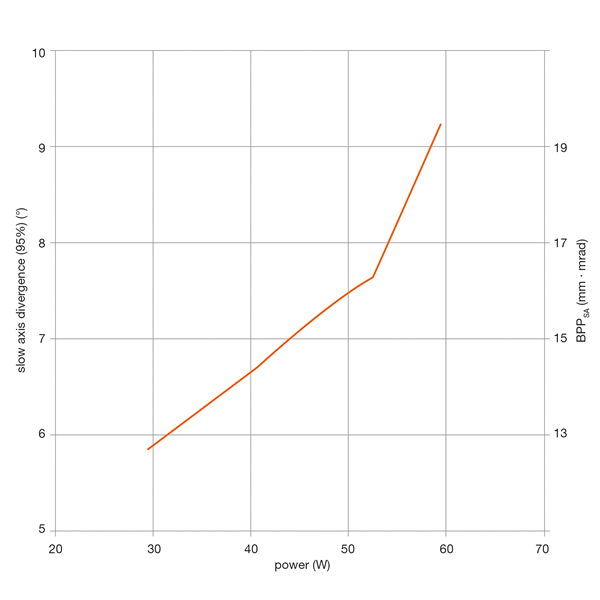

Brilliant laser sources generate a narrow beam of light with extremely small beam divergence and high power density. The lateral divergence, calculated for the portion of the laser beam containing 95% of the optical output power, is between 6° at 30W and approx. 9.5° at 60 W.

With its high brilliance, the SPL BF98-40-5 aims to set standards for fibre-coupled systems. The beam quality of a laser is a crucial factor for coupling laser light into optical fibres. The lower the brilliance, the less light is coupled into the fibre. This, in turn, makes the systems more inefficient and more expensive. Conversely, a brilliant light source greatly simplifies the design of the optical system.

fibre-coupled diode laser systems are used predominantly in the automobile industry for vehicle chassis welding, soldering and coating. The laser diodes are also often used for pumping fibre lasers. The wavelength of 976nm is ideal for pumping ytterbium-doped fibre lasers in particular. These are laser types that can be used for cutting metal, thanks to their excellent beam quality. Osram has specifically matched the wavelength of the SPL BF98-40-5 to this pumping application.

The laser bar offers electro-optical efficiency of, for example, 65% at 44W, thus reducing the level of cooling needed for the laser diode and improving system efficiency. The low temperature rise at the chip results in the laser exhibiting very good aging stability. Tests show a drop in output of less than 1% after 4000 hours of operation at an optical output of 65W and a cooling water temperature of 25°C.

Osram Opto Semiconductors defined the fundamental principles for developing the high-power high-brilliance laser bar within the HEMILAS project sponsored by the German Ministry for Education and Research (BMBF).

“Our laser bar can significantly reduce the system costs for fibre-coupled diode lasers,” said Sevugan Nagappan, Product Marketing Manager, IR, Osram Opto Semiconductors.