Design enhances LED bulb thermal management

Adriana Druma, Aavid, describes how design enhancement and an innovative production process can improve thermal management in LED light bulbs.

Tremendous improvements in the LED lighting technologies in the past decade have led to LED bulbs being used more and more frequently for replacing the high power consuming incandescent bulbs. Unlike the traditional bulbs, LED bulbs (above) deliver soft, warm light and consume 82% less energy than traditional bulbs and are designed to last 25 times longer.

High temperatures can significantly alter the light output of the LEDs over time, reducing their lifetime as well as affecting colour shift. Therefore, finding the best thermal solution is critical when it comes to LEDs.

For reliability, most LED cooling solutions must be passive cooling (natural convection). For passive cooling, people typically use a heatsink with different shapes to dissipate heat, making the heatsink a major part in the LED assembly design. A passive LED heatsink, when attached to the LED assembly, directs much of the dissipated heat away from the LEDs and into itself. For this reason, most LED heatsinks are made of conductive metals.

The heatsink is typically made of aluminum die cast (due to its very complex shape) which has very low thermal conductivity. Therefore, the heatsink design will often be bulky and heavy. Aavid Thermalloy can improve the heatsink design by using the high density die cast aluminum material which has a thermal conductivity close to extruded aluminum. High density die casting has been developed by Aavid Thermalloy together with its university partners.

The challenge

In LED heatsink design, each of the three heat transfer modes (conduction, convection, and radiation) plays an important role. Convection allows the heat transfer from the LEDs to the ambient, conduction heat transfer conducts the heat away from the LED to a piece of metal (typically a heatsink with fins). Radiation improves the heat transfer from the heatsink surface to the ambient when a high emissivity coating or painting is applied to the heatsink.

In general, the blacker or duller the heatsink surface is, the emissivity is closer to perfect which is that of the black body.

The challenge with designing the heatsink for LED lighting lies in the very complex geometry dictated by the aesthetic appearance or accessibility to the LED area. Although some simplifications could be done without altering the thermal solution very much, often it is necessary that design details be maintained and captured in the Computation Fluid Dynamics (CFD) analysis. Using CFD analysis early in the design phase reduces time and cost to create physical prototypes. In this case, the company’s engineering team uses a combination of software tools to model the complex, intrigued geometry and perform an accurate and reliable CFD analysis.

Design process

When designing cooling solutions, the size and weight can be directly translated to the cost. The company’s design team wanted to investigate the weight and size of the heatsink design used by a leading LED bulb manufacturer by replacing their die cast aluminum with the High Density Die Cast (HDDC) aluminum. Weight and size reduction ultimately leads to cost reduction and gives the LED bulb a less bulky look.

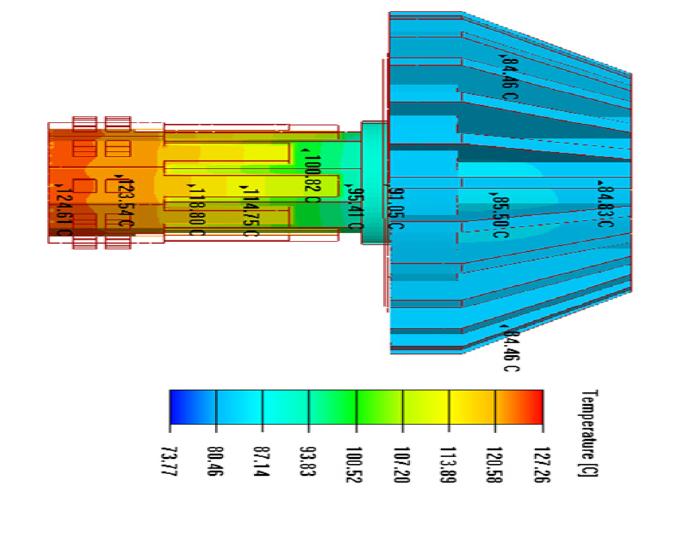

The design process was performed in several steps. The design team purchased various sizes of LED bulbs and removed their bulbs to access the LED heatsink. They then created mechanical drawings of the LED heatsinks and used various software tools to import the heatsink complex geometry into the simulation software tool and performed the CFD analysis. If the LED heatsink was made of aluminum die cast, the temperature of the LED was about 137°C. Replacing the die cast aluminum by HDDC aluminum, the temperature of the LED dropped by 10°C.

Delivering results

The design team showed that despite of the challenges of heatsink geometry, CFD analysis can be performed without altering the heatsink design. It is important to capture the details and complexity of the heatsink design when it comes to LEDs. High temperatures lead to decreased light quality and LED lifetime (see below).

CFD analysis was used to model the heatsink performance.

Members of the team showed that by changing the heatsink material from die cast aluminum to HDDC aluminum, the heatsink could be reduced in size and weight. To prove this, the team interchanged the heatsink of a lower power bulb (and therefore smaller footprint) with the heatsink of the higher power bulb and showed that the thermal performance of the LED bulb was still lower than its maximum limit.

One further step, was to show that by replacing the dry contact (air, which is a poor conductor of heat) between the LED aluminum PCB board and the die cast aluminum heatsink with a thermal interface material, the thermal performance of the LED bulb can be further improved.

The design team used its modeling capability to accurately predict heat transfer and temperature distribution for any LED cooling solution and design configuration.