Address LED inrush current within a lighting system design

Andy Wall, CEO of Sunpower Technology, looks at the issue of LED inrush current and how to allow for it within an overall lighting system design.

Many LED lighting arrays include current-limiting circuitry; these can be successfully driven with constant voltage LED drivers. Where arrays of connected LEDs do not include provision for current limiting, constant current LED drivers must be specified to manage the LEDs’ steady-state current demand.

Irrespective of the LED drivers used, provision must also be made for the inrush current they draw when power is applied, especially if the LED lighting scheme is being designed to replace an existing incandescent lighting installation. LED lamps are cooler-running, with longer life expectancy, better efficiency and lower maintenance needs than most other lighting types. They are also compact and emit light as a narrow, directionally-controllable beam; such features allow accurately-profiled, efficient LED lighting schemes. These advantages, together with falling prices, are feeding market growth. According to a recent Lux Research survey, the global market for LED luminaires is set for over 12-fold growth over the next decade; from $2bn today to $25bn in 2023.

In most lighting applications, this situation makes the decision to go LED an easy one. However this typically involves a transition from incandescent or fluorescent lighting; if so, adequate allowance must be made for the inrush current drawn by LEDs, which can be twice that of incandescent devices.

Causes and solutions

Imposition of an inrush arises because LED devices operate from a DC current, usually delivered by an AC/DC power supply unit (PSU). This PSU, often referred to as an LED driver, presents a capacitive load to the supply mains and this causes a voltage peak and inrush current surge during power-up. The magnitude of the voltage peak depends on the phase angle of the supply AC sine wave at the moment of start-up. The worst case occurs if this angle is 90°, when the voltage across the primary side of the PSU can rise from 0 to 300V on a 230VAC grid almost instantly.

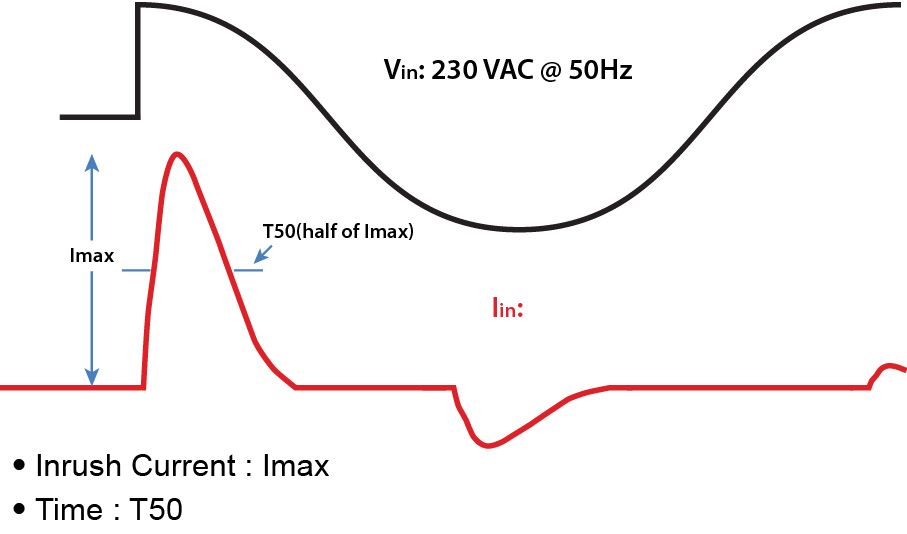

Figure 1 - Inrush current waveform

Figure 1 shows the nature of the inrush current and its peak, IMAX. T50 is the time duration in which the inrush current pulse is equal to 50% of IMAX.

Designers often limit the inrush current by connecting a power thermistor (NTC) in series with the PSU’s capacitance. At start-up the thermistor is cold and has a high resistance; this limits the current drawn by the PSU’s input capacitance. Then, as current flows, the thermistor dissipates power and warms up rapidly, so its resistance decreases until a state of equilibrium is reached. However this solution, though simple, is not ideal because the thermistor even when warm still has some resistance, which wastefully dissipates power. It can be improved by adding a relay to bypass the thermistor after the inrush pulse has decayed, usually tens of milliseconds after start-up.

Even with thermistor protection, some inrush current is inevitable when power is applied to an LED lighting installation. Within limits, this is acceptable; however excessive electrical energy can permanently damage electronic equipment and weld relay contacts together. For this reason, miniature circuit breakers (MCBs) should be used to protect cables and equipment from such overloads as well short circuit events and fault conditions.

MCBs operate by tripping open on detection of an overload or short circuit condition. The tripping point relates to the magnitude of electrical energy being passed – and this in turn depends significantly on both the inrush current peak value and its time duration. Accordingly, an MCB could be tripped either by a high peak of short duration, or a lower peak of longer duration. In either case, the objective is to ensure that the MCB trips before passing excessive energy, yet does not trip and cause lighting blackouts when it does not need to.

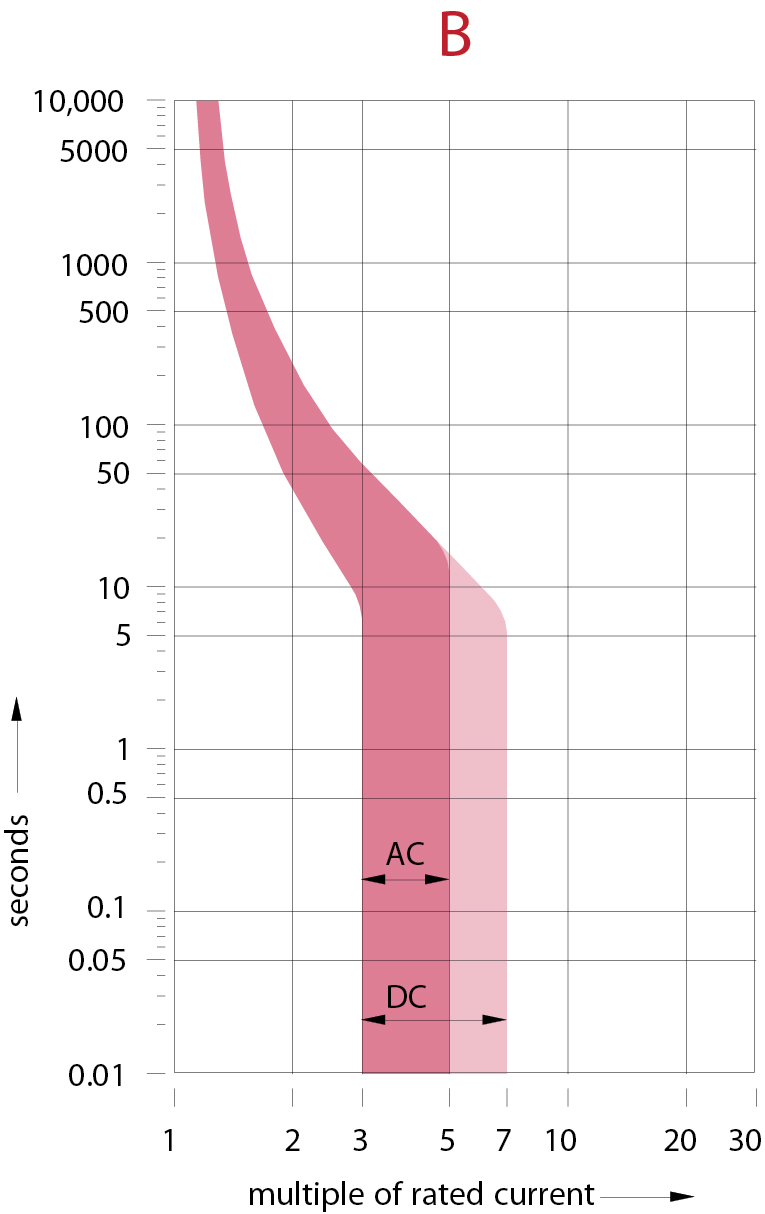

Figure 2 - B trip characteristic curve for an ABB S200 type MCB

MCB manufacturers’ solution to this is to offer a choice of trip characteristics in addition to their steady-state current rating; widely accepted standards are B,C,D, K and Z. Each standard can be represented as a curve showing how trip time decreases as inrush current, expressed as a multiple of rated current, increases. Figure 2 is an example of a B trip characteristic standard for an ABB S200 MCB. Note that if the B setpoint of three times rated is reached, the MCB will trip virtually instantaneously, whereas it will tolerate periods extending into minutes or more for much lower levels of current overload. Types B,C and D are the most frequently used trip characteristics in LED lighting applications. Type B devices are typically used in domestic and light commercial applications where surges are low. Traditionally these have come from a small number of fluorescent fittings. Type C MCBs are more focused on commercial and industrial applications with larger numbers of fluorescent fittings, as well as possibly motors. Type D characteristics are required in more specialised applications, for example where X-ray machines, transformers or other high-inrush equipment is present.

Multiple drivers

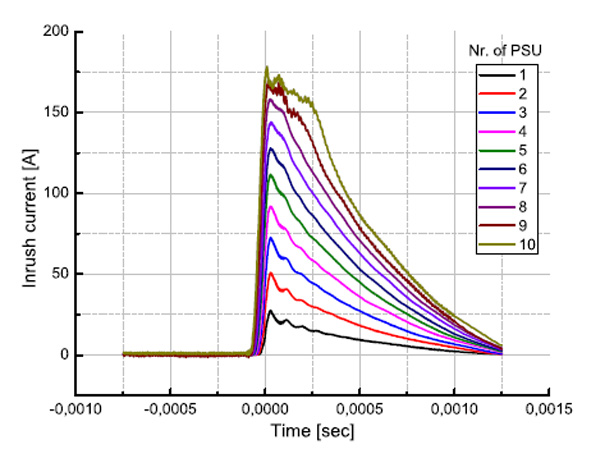

Figure 3 - Showing how inrush current increases as drivers are added to MCB

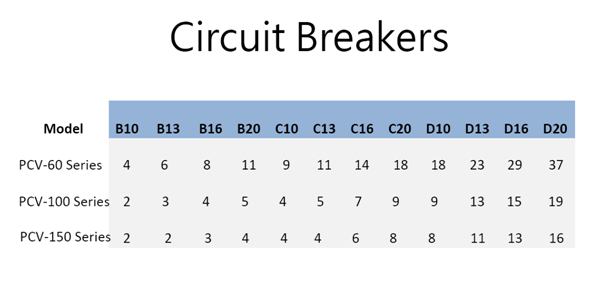

Another key consideration in specifying MCBs for LED lighting relates to connecting a number of LED drivers to a single MCB. As Figure 3 shows, inrush current does not grow linearly with increased numbers of drivers. Table 1 translates this into practical numbers of some Sunpower LED drivers that can be connected to single ABB S200 MCBs with B,C and D trip characteristics, and ratings of 10-20A. Note that these figures are suggestions only, and that all MCB/driver systems should be tested for compatibility. Other factors affecting the power installation’s capability to support an LED lighting array include the age and condition of the circuit breakers and cabling, building earthing, cable impedances and cable lengths.

Table 1 - Numbers of Sunpower LED drivers that can be connected to MCBs of different ratings and trip characteristics