The importance of storage in the factory of the future

‘Factories of the future’ (FoF) is the European Union’s €1.15bn public private partnership for advanced manufacturing and production. It is the collaborative integration of Information Communicational Technology (ICT) and Automation Technology (AT) that has shifted the diverse manufacturing landscape.

Its advances demand flexibility, safety, productivity and above all, reliability. It is a solution orientated approach, where greater resource efficiency and higher production quality alone are no longer sufficient.

The International Federation of Robotics has predicted that over three million industry robots will be integrated into supply chains by 2020 - the backbone of these robots are efficient data transactions and secure storage. Automated systems and robots supply actionable information in the form of highly sensitive data, to fine-tune and optimise performance, utilise machine learning and ensure safety, reliability and security.

In the past, factories had few computers, with few components, resulting in a relatively low accumulated risk of failure. Today, the factory of the future demands eco-systems operating entirely off embedded computers. With a plethora of components, ICT and AT have a significantly higher accumulated risk of failure.

Since a factories dependency grows with each added component and any failing component can trigger a system failure or factory halt, factories of the future demand robust system architectures that do not compromise control to power failure. The quality of these solutions comes down to the quality of the storage embedded into the systems. This is why abiding by the Industrial Quotient is integral when designing storage systems for the factory of the future.

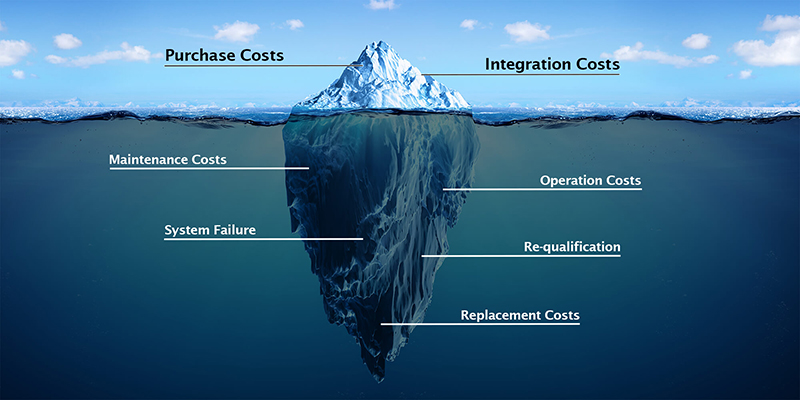

As mentioned earlier, it is no longer enough to master greater resource efficiency and higher production quality. Since the backbone of ICT and AT is efficient data transactions and secure storage, the storage modules managing the host demand application specific optimisation, ruggedised products, highly reliable components, extensive testing and longevity. Implementing high quality storage-modules is an integral step in achieving safe, reliable and secure innovations at a lower Total Cost of Ownership.

How significant is the flash memory controller in ICT and AT?

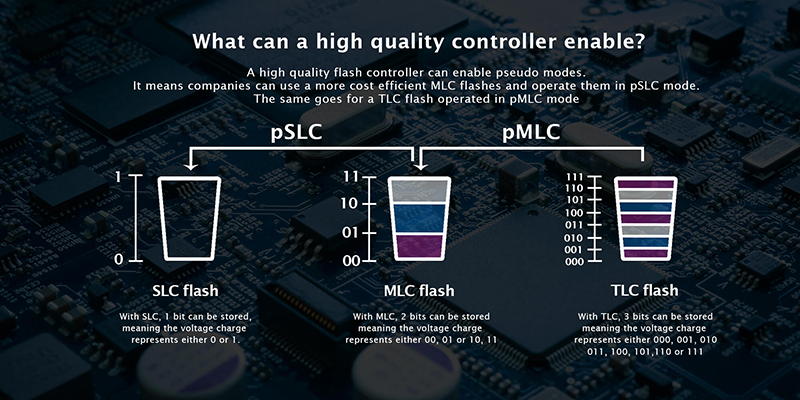

Storage systems inside ICT and AT come with a unique set of challenges. Therefore, it is important to understand how flash memory controllers work towards making these systems as reliable as possible. Today, NAND flash memory controllers are the brains behind all global non-volatile data transfers.

What appears to be a tiny chip, communicates and manages masses of data between the host interface and the flash memory array which then ultimately stores the data. As manufacturers have increased flash densities, the physical and logical demands on controller technology have grown at an exponential rate.

Factory automation requires an industrial strength flash memory controller designed to manage sensitive data, with strong error correction coding, reliability eco-systems, and firmware features to prevent storage system failure. The flash controller should have all these features and mechanisms, and run them without compromising system performance over time. Embedded IPCs are designed to establish safe, productive environments that run on lower overall costs. However, none of this can be achieved without reliability, because the moment a system unexpectedly fails an abundance of costly resources must be invested.

Learning data generated by Artificial Intelligence furthermore demands reliable storage. Compromised data from learned things could take significant time to be re-learnt and have serious ramifications on supply chains. A fully connected supply chain requires collaborative robots, decentralised production steering and using big data and analytics to manage factories.

In today’s factories, robots can work together with humans without protective fences. For instance in the power train preassembly’s like that at Volkswagens plant in Wolfsburg Germany, a robot assists workers by tightening screws. System like this demands safe and predictable movements, which stem from stable and efficient data transactions.

Decentralised Production Steering allows companies to use advanced technology to enable communication among work pieces, machines and people. This saves time, resources and lowers the risk of human error. However, similarly to collaborative robots, DSP requires masses of data to be communicated across factories. Furthermore, manufacturers are using ever more applications to analyse data and use predictive analytics to examine parameters and make decisions that influence and ensure quality across the supply chain.

The overall success and reliability of all these aspects falls on the quality and capability of the flash memory controller in processing the communicative data and ensuring it is secure and optimised for its exact work load.

Security features can be integrated for secure foundations

Nowadays, the complete manufacturing know-how of a company is no longer as prevalent in the minds of its people as it is in a digitally stored in ICT and AT. For this reason, security breaches can lead to a whole loss of sensitive knowledge. Hacked systems can also result in compromised and dangerous system behaviour. Certain flash memory controllers allow for extra security features to be integrated to ensure the foundations for a secure system are in place.

Industrial PCs, testing and measurement equipment as well as data loggers are transforming every area of our lives and when they unexpectedly fail, there can be serious ramifications on manufacturing environments and global production, the stock market and the livelihood of those involved. Cost drives many decisions; but for the factory of the future, repair, maintenance and replacement costs can be significantly higher than the initial bill of materials. This is why when it comes to ICT and AT quality is king.

Why power fail management is crucial

Supply chains are hinged on power and if a black-out, or power outage occurs, systems must either have a reliable black-up power source or shut-down securely without compromising the data being processed. Power fail robustness is a well-known feature of flash memory controllers. It is one of the most vital features for industrially demanding storage systems to ensure immunity against compromised power.

This feature must dynamically maintain data integrity throughout events that could compromise not only individual machines, but entire supply chains. The FoF is heavily concentrated on machine-learning, a concept in which robots gather data and communicate with each other to optimise best practises. Systems like this, demand best in class power fail management to ensure the entire chain of machines and equipment are not hinged on a failing machine that could jeopardise learning data and pull down system performance.

It is often assumed that power fail robustness is a standard firmware feature, carried out similarly by different controller manufacturers. But this is not the case. The controller is the brain, managing the flash. And like all brains, there are different IQ levels. For one to simply look at a data sheet and tick off the necessary boxes would be naive as there’s no way of ensuring the processes are carried out to the necessary standard without efficient power cycling tests.

Targeting stringent industrial applications is a goal of Hyperstone. Consequently, the company have placed a strong focus on power fail robustness which is deeply embedded in not only their hardware design but also their basic firmware architecture to avoid corrupt data and failing devices. Sudden power failures can hit a storage system during writing, reading, erasing, mapping updates and background firmware operations.

Hyperstone products are designed to detect power-downs in order to stop and protect all operations immediately. Ultimately, one should not simply tick the boxes without further insight– these features are never the same. If you are designing an industrial grade storage system, it is best advised that you inform yourself as to the technology behind the data sheet and run a substantial number of power cycle tests before making concrete decisions.

The factory of the future, the robots and the technology embodying them have their backbone resting on reliable non-volatile storage. It is the job of system integrators to ensure that the most reliable flash memory controllers are used integrated into the cards and modules that end up in these systems.

The decision of which flash memory controller should support your storage system can be made by you and can greatly impact the quality of your end product. The features that make up an industrial storage system, power fail management and further design flexibility are essential for industrial designs and this is what Hyperstone specialises in.