NI cooperates with industrial giants to build IIoT ecosystem

If there is an industry that can embody a country’s comprehensive national strength most typically and gradually reconstruct the new pattern of global competitiveness, it is intelligent manufacturing. The second Made in China 2025 (Shenzhen) Summit Forum themed by 'Smart Transformation of Global Manufacturing' was convened as scheduled on 8th and 9th April.

Invited by Industrial 4.0 Lab of Tongji University, Rahman Jamal, the global CTO and CMO of National Instruments (here in after referred to as 'NI') joined the forum and had in-depth discussion with over 1,000 domestic and foreign manufacturing experts on how to transform China into a leading manufacturing power in an all-round converged era.

Figure 1: Rahman Jamal, Global CTO and CMO at NI sharing NI's ecologic allocation in IIoT at the forum.

Figure 1: Rahman Jamal, Global CTO and CMO at NI sharing NI's ecologic allocation in IIoT at the forum.

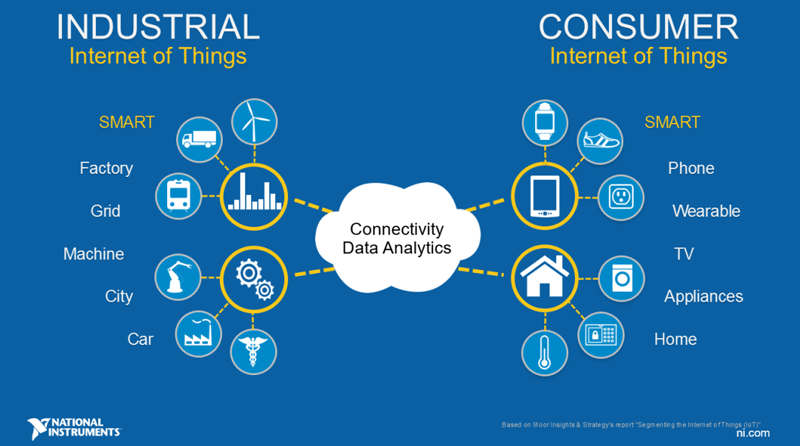

In the presentation, Jamal highlighted the key role of Industrial Big Data played in Industrial Internet of Things (IIoT). The real value of Big Data lies in the whole process from intelligent collection, processing and analysis of industrial big data to its influences on later-stage enterprise decisions and industrial trends.

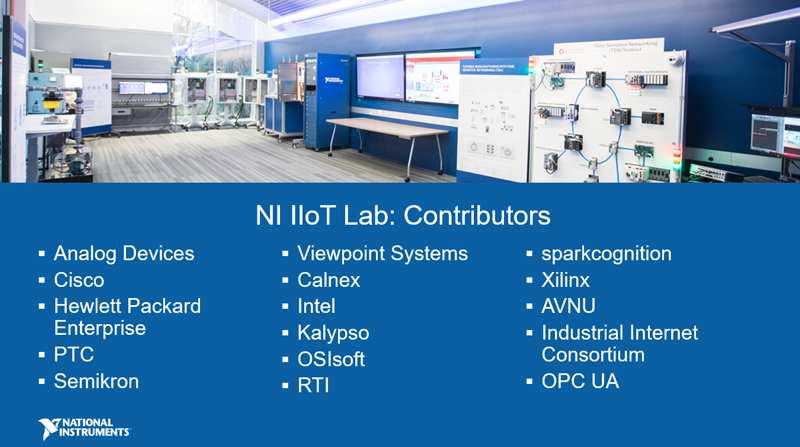

NI is cooperating with many industrial giants such as Cisco and Intel to build an IIoT Lab in its headquarter in US Austin, expecting to promote the rapid implementation of IIoT all around the world and accelerate the advent of intelligent manufacturing through mining the value in industrial big data.

The significance of industrial big data lies in value-added and future forecast

“As predicted by experts, there will be 50 billion connected smart devices in the world by 2020,” said Jamal. “They will form a huge network, which symbolises the future of the world.”

Interconnection further highlights the essences of the world and the interconnection 'gene' will take IIoT as carrier through intelligent manufacturing.

As pointed out by ABI Research, more than 13 million wired and wireless connections will be added in the global IIoT market in 2017, wherein the total amount of accumulated connection will exceed 53 million.

Interconnection of things creates Big Data and the Industrial Big Data is the core driving force for IIoT market prospect which is embodied by values. As analysed by Lux Research, the global IIoT output value will reach $151bn by 2020.

Figure 2: Intelligent collection and analysis of interconnected big data is the foundation for decision making and future forecast

Figure 2: Intelligent collection and analysis of interconnected big data is the foundation for decision making and future forecast

“In the era of IIoT, the data volume grow at exponential rates. So it is important to know how to extract the value behind the data,” explained Jamal.

Through intelligent collection and analysis of industrial big data, demands and manufacturing could be forecasted and risks in latent problems can be solved and avoided. Besides, intelligent supply chains can be built from the 360° panorama digital perspective to provide decision support for production management and factory transformation of enterprises.

The significance of industrial big data lies in the added industrial value as well as the ability to forecast for future.

However, “The huge and complicated data also brings big challenges in the data manipulation, interconnection and interoperability.” added Jamal.

With decades of experience in testing and measurement area, NI well knows the importance to build a universal, open and flexible platform. The universal platform based on flexible software and modular hardware enables NI to achieve device interconnection and interoperability in a wider range.

Whether it’s simulated IoT M2M Gateway used to collect, summarise and digitalise analog data, or InsightCM Enterprise suite that provides cloud-level data management and transfer, data analysis and system management software for Big Data analysis and mining, the NI data acquisition platform labelled with commonality can lower the requirements of intelligent data collection and analysis for IIoT, enables mutual integration of information on technological, product and management level, and helps enterprises improve the production processes, organisational management and service upgrades, thus enhancing enterprises’ competitiveness in the market.

Industrial giants gather to brainstorm, IIoT lab builds the IIoT ecosystem

If building a common platform is deemed as the foundation of NI’s industrial layout, it would be fair to say that the commanding point of NI IIoT layout is to facilitate industry university research cooperation in the industry and get linkage with industrial giants.

Since 2016, NI has kept close cooperation with Industry 4.0 - Smart Factory Lab of Tongji University to build NI IIoT Lab to do key technologies research, experimental verification and technology demonstration of predictive maintenance. China’s first Industry 4.0 - Smart factory Lab was established in Jiading Campus of Tongji University on 28th October 2014. After expansion, the overall area of lab reaches 500m2, composed of various supporting labs with discrete industry and process industry as the main subject.

The lab responds to the 'leading manufacturing power' strategy of China by targeting education, scientific research and social services of German Industry 4.0 and American Industrial Internet. In fact, the cooperation between NI and Industry 4.0 - Smart factory Lab of Tongji University mutually complement each other’s industrial chains.

“Based on the domestic leading academic position of Tongji University Industry 4.0 - Smart factory Lab plus strong scientific research strength of expert teams as well as NI’s rich engineering experience in fields such as data collection and asset condition monitoring, a new mode is developed to facilitate industry-university-research cooperation and Sino-foreign cooperation for intelligent manufacturing.” said Chen Mingqiang, Director of Industry 4.0 Lab of Tongji University and Vice Dean of Tongji University CDHAW.

Cooperation and ecology have become the key elements in the development of IIoT.

“In the future, no single vendor can provide complete solutions independently. Instead, the win-win success can be only achieved through ‘Platform’ and ‘Ecosystem’.” stressed Jamal.

“The platform mentioned here refers to NI software-defined platform, and Ecosystem means an ecologic system of NI in different fields. Through the combination of the core platform and ecosystem, the application and scopes of products can be expanded in corresponding segmented fields.”

This is an era of friends fight.

On 11th January 2017, NI cooperated with ADI, AVNU Alliance, Cisco, Hewlett Packard, Industrial Internet Consortium, Intel, Kalypso, OPC Foundation, OSIsoft, PTC, Real-Time Innovations, SparkCognition, Semikon, Viewpoint Systems and Xilinx to build an IIoT Lab which is first of its kind, focusing on areas such as micro-grid control and communication, advanced manufacturing control and heavy equipment asset monitoring.

Figure 3: The world's first NI IIoT lab was formally established, supported by a wide range of industry-leading companies.

Figure 3: The world's first NI IIoT lab was formally established, supported by a wide range of industry-leading companies.

At the forum, Jamal made in-depth description of three typical use cases of IIoT Lab:

The first one is industrial asset monitoring. Under the general trend of IIoT, predictive maintenance of large machines and equipment gradually becomes necessary.

Based on the condition monitoring and predictive maintenance programme of pumps/motors setup, NI IIoT Lab applies Internet of Things technologies in the monitoring of heavy equipment through the combination of data collection, analysis, edge computing with software-defined platform, which can effectively help enterprises make smarter decisions, maximise up-time of operation assets and reduce the maintenance cost.

The second use case is TSN flexible manufacturing.

Compared with current standard and dedicated Ethernet protocols, the new standard of Time-Sensitive Networking (TSN) will significantly improve performances such as bandwidth, safety and interoperability to ensure critical time-sensitive data can be transferred on time via standard network infrastructure, which requires low communication delay and minimum jitter to meet the strict requirements of closed-loop control and is critical to industrial applications such as process and machine control.

As one of the members that develop and promote TSN standard, NI demonstrates the cooperative technologies from 12 companies on TSN network via IIC testbed in its IIoT Lab.

The final one is micro-grid control and communication. Based on the IIC testbed, IIoT Lab focuses on develop open technologies of edge monitoring and micro-grid control and maintains scalability and interoperability between different vendors and protocol standards.

As advocated by Jamal once and again, NI IIoT Lab expects to cooperate with giants on upstream and downstream of the industrial chain and take intelligent collection and analysis of industrial big data as the entry point to accelerate integration and evolution of worldwide IIoT.

Turning data into insight, NI IIoT Lab aims to integrate and extract the advanced aspects in global IIoT field through the 'brainstorm' of industrial giants to provide enterprises and industries with the ability to mining data value, without being limited to only one product or approach.

Through digitalised panorama service, NI IIoT Lab can help enterprises analyse decisions and comprehensively optimise management value chain to ultimately create a revolutionary and innovated industrial mode, which offers spur to the proliferation of IIoT all around the world.

Click here to watch the video and download the IIoT Infographic.