The fourth Industrial Revolution?

If you live in Germany the chances are that you’ve already heard quite a bit about Industry 4.0, where it has been in common use since the Hanover Fair — the world's biggest industrial gathering — in 2011. It was given authority in October the following year when a Working Group on Industry 4.0 comprising major companies presented a set of Industry 4.0 implementation recommendations to the German federal government. So what is Industry 4.0 and what will it mean? And how does it relate to the Internet of Things? By Graham Maggs, EMEA Marketing Director at Mouser.

Industry 4.0 proposes a fourth industrial revolution. The first Industrial Revolution (Industry 1.0) is accepted as the harnessing of water and steam power to mechanise production. The second industrial revolution, pioneered by Henry Ford and others, introduced mass production using electricity. Industry 3.0 is known more usually as the digital revolution or digital age which increases levels of automation using electronics systems and IT. That’s a fast romp through 250 years (give or take) of industrial history, and so we come to Industry 4.0.

Whether we are on the verge of another ‘revolution’ or not, significant changes are occurring. Industry 4.0 is a specific project within German government’s high-tech strategy program, which promotes the computerisation of traditional industries such as manufacturing and has as its goals the intelligent or Smart factory, characterised by adaptability, efficiency and ergonomics, and the creation of partnerships in business ecosystems and value processes.

Therefore, Industry 4.0 seems as to be good a label as any for developments in manufacturing and production which are resulting from technology developments such as cyber-physical systems and the Internet of Things.

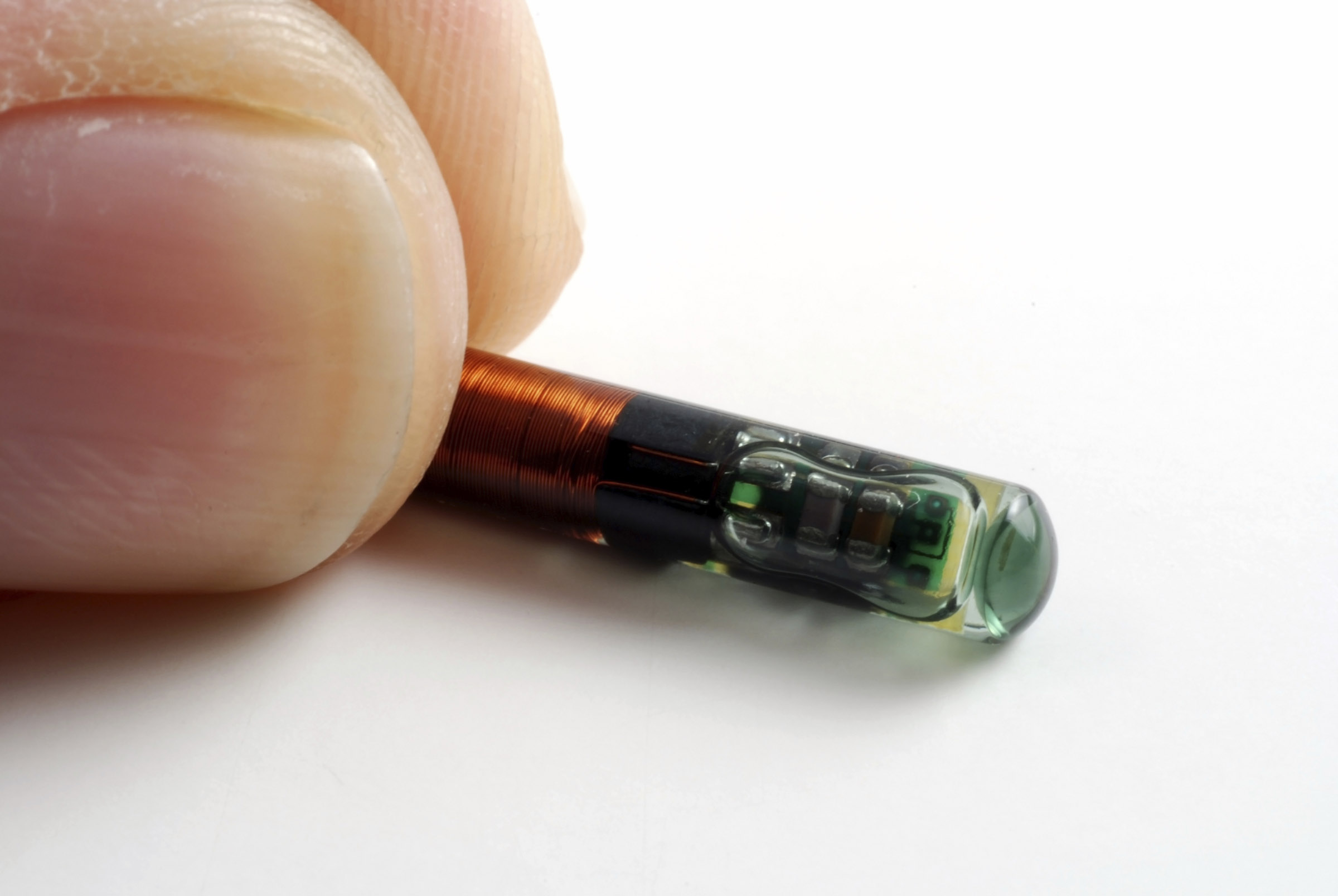

Dr. James Truchard, CEO of National Instruments first defined cyber-physical systems (CPS) in 2006, based on a virtual representation of a manufacturing process in software. Industry 4.0 envisages cyber-physical production systems where smart products use sensors to instruct automated production equipment as to how they should be processed. To put it more simply, in the near future, factories will monitor, control and optimise manufacturing processes largely by themselves. To achieve this, intelligent tools and new software for structuring data flows will be required, and the vast majority of machines — as well as materials and part-processed goods — will have miniaturised processors, storage units, sensors, and transmitters embedded in them. All of these developments will enable products and machines to communicate with each another and exchange commands wirelessly, either directly or via the Internet of Things (IoT). The result, it is hoped, will be a much more flexible production environment, with less central control and more intelligence built into equipment locally to optimise efficient processing.

This is the current understanding and hope for Industry 4.0, and it is currently more a high-level concept rather than a reality. However, on 8 April 2013 at the Hanover Fair the final report of the Working Group Industry 4.0 was presented, so it is a concept that is gaining momentum. And as with any ‘revolution’ it draws together many concepts that exist today and are well understood.

Sensor-centric

Already, more and more, sensors and being incorporated into every manufacturing process. The raw data they capture provides feedback that enables real-time monitoring and adjustment of various processes, increasing efficiency. To implement such fine control, industrial control systems must become more complex and accurate — and be much more widely distributed throughout the shop floor. These localised control systems will communicate through wireless mesh networks, enabling processes to be reconfigured in situ in real time. Traditional, rigid centralised control regimes do not allow this flexibility.

A couple of other factors can be expected. Firstly, since it is likely to be difficult if not impossible to predict all the changes to the working environment that control systems will need to operate within, the use of programmable logic will become more prevalent. Secondly, intelligent, interconnected embedded devices will become ubiquitous, so programming needs to be considered.

One intriguing point to consider about Industry 4.0 — and one that supports the view that it will move from high-level concept to working reality in a relatively short time — is that it could be implemented with the technologies that we have available today.

Sensors of all types are available off the shelf. RFID and GPS tracking modules are routinely used in many industries. Our smart phones use an exponentially-growing number of apps to access the internet and add to our lives by informing, monitoring and activating. It is just a case of using the information gathered as a product moves through a factory in an intelligent way to avoid shortages — or over-production.

Yet many factors still need to come together for Industry 4.0 to be easy to implement. Currently, for example, there is no agreement on which standard technology will be used to transmit the signals required to enable the Internet of Things’ cloud. If we use the same frequencies as the standard internet, then we may run out of bandwidth. Yet much of the information that would be required to keep machines in touch with machines is simple, small data chunks — machines wouldn’t routinely post 200 pictures to the internet! So maybe we can opt for simpler mechanisms. Unless there is standardisation, the market may be splintered and uneconomic.

Most of all, though, manufacturing companies need to embrace the concept of Industry 4.0. Mouser focuses on providing design engineers with the latest technologies and products for their newest designs, so designers looking to implement Industry 4.0 will find a wealth of ideas including application notes and articles on Mouser’s website at http://www.mouser.com/applications/industrial_applications/.