Collaboration enables smarter model-based design

Wind River is working with MathWorks to integrate Wind River Simics with Simulink for improved model-based design workflows. This collaboration creates smarter system verification by enabling testing and co-simulation of combined design and platform models, and helps drive better designs while removing risk from future development, test, and integration.

By alleviating these risks, this solution can be particularly valuable to engineering teams developing complex and safety-critical products for industries such as aerospace and defence, automotive, and industrial markets.

Model-based design is transforming the way engineers and scientists work by moving design tasks from the lab and field to the desktop. In model-based design, a system model is at the center of the development process, from requirements development through design, implementation, and testing. When software and hardware implementation requirements such as fixed-point and timing behavior are included in model-based design, teams can automatically generate code for embedded deployment and create test benches for system verification, saving time and avoiding the introduction of manually coded errors.

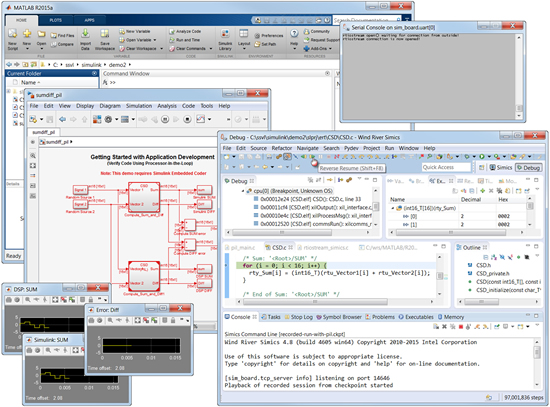

As part of an ongoing collaboration with MathWorks, Wind River has integrated Simics with Simulink to support Processor-In-the-Loop (PIL) testing. Simulink is a block diagram environment for multi-domain simulation and model-based design, and has widespread usage for model-based design in the embedded system market. It supports simulation, automatic code generation, and continuous test and verification of embedded systems.

PIL testing checks that code generated from a Simulink controller model using Embedded Coder will run correctly on the actual processor that will be used in the final target system. Prior to PIL testing, control algorithms are typically developed and validated on the host, using a high-precision floating point mathematics and with no concern for the implementation system and any cross development tools such as compilers that can impact on-target behavior. The Simics PIL integration for Simulink is available for all Simics customers.

“With the Simulink–Simics PIL integration, MathWorks customers can reuse their Simulink system models to verify and assess code generated from Simulink control algorithms on their embedded processor without the need to use actual hardware boards and debugging tools,” said Paul Barnard, marketing director of design automation at MathWorks. “Simics-based PIL testing provides easy access to target systems enabling architecture-based testing and execution profiling early and often, reducing the risk of late-stage integration problems.”

“This Simics–Simulink PIL integration is a great example of how Simics addresses the need for access to sufficient numbers of hardware targets, dependable collaboration, and automation for greater efficiency. Model-based developers can more easily access embedded targets for testing, collaborate by saving and sharing controller software simulations, and better automate early-stage, hardware-specific testing with Simics simulations,” said Michel Genard, vice president and general manager of Simics at Wind River. “Using Simics in model-based design workflows allows software developers to run their model-based code sooner, transforming their project timelines.”