Adapting to the future: a PCB manufacturer’s journey in cleaning fluid transition

Transitioning to a new vapor degreasing fluid is no small feat for PCB manufacturers, especially those who have been using a long relied on, established fluid to meet their stringent cleanliness standards. Elizabeth Norwood, Senior Chemist at MicroCare, LLC, further discusses.

These vapor degreasing fluids play a critical role in removing flux reside, dust and fingerprints from PCBs, impacting both the performance and longevity of the boards.

However, when fluid suppliers discontinue these trusted chemistries, PCB manufacturers are faced with the challenge of finding an optimal long-term replacement that minimises operational disruptions. This process involves a thorough evaluation of various key factors, such as vapor degreaser compatibility, substrate preservation, long-term availability, and supplier support.

This transition can be particularly complex when dealing with tightly packed boards, low stand-off components, and delicate substrates that require cleaning fluids with specific physical properties. For instance, miniature or densely populated PCBs typically require a high-density, low viscosity cleaning fluid that allows the fluid to flow around and under the components to clean thoroughly, yet dry quickly without leaving residue behind.

Managing the unexpected

This story of one PCB maker, a provider of high-performance assemblies for the aerospace and defense markets, is a testament to the challenges and opportunities that come with a cleaning fluid transition.

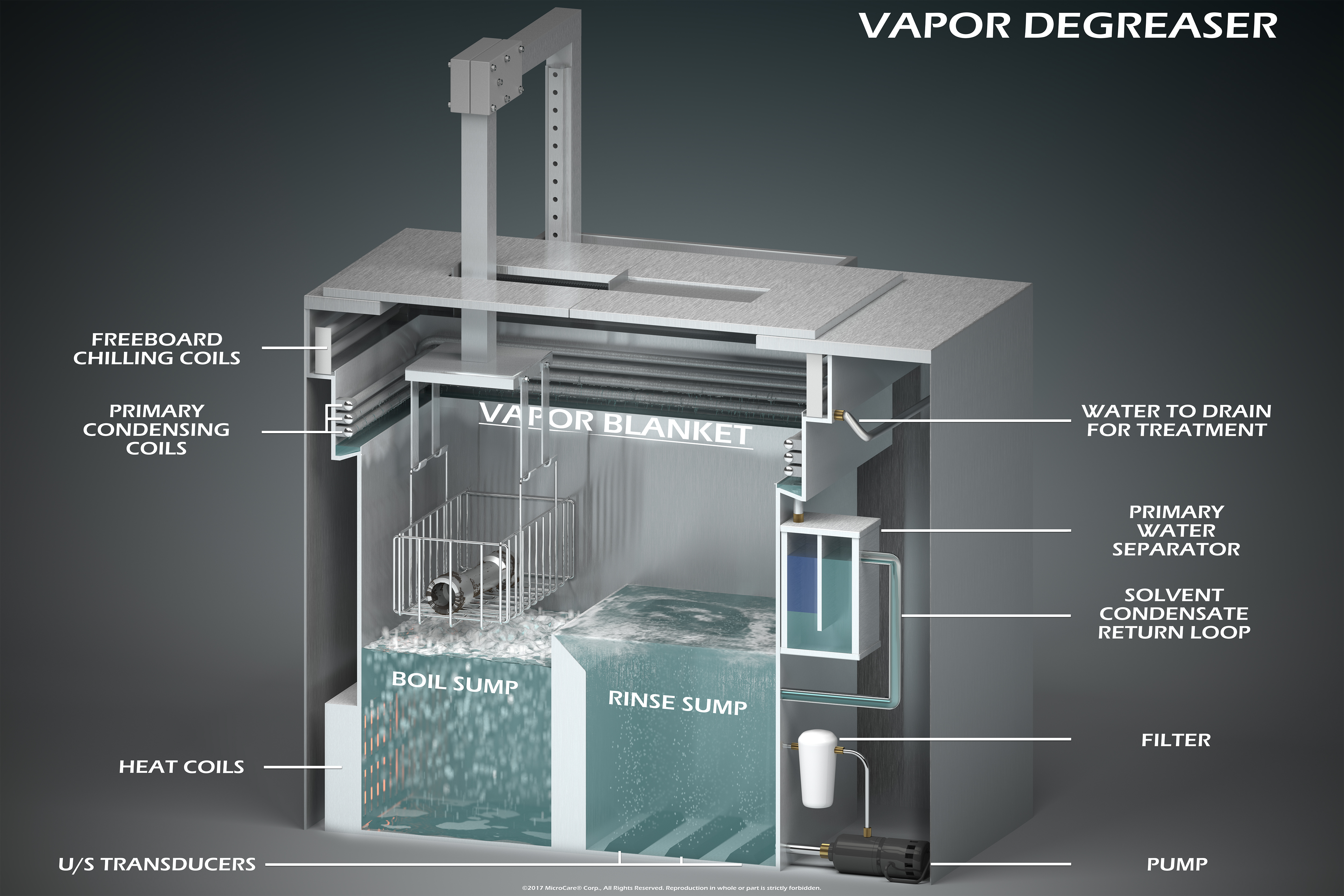

The PCB manufacturer’s commitment to delivering top-quality products across the electronics industry requires precision and impeccable PCB cleanliness in their manufacturing process. In 2022, they were using a new vapor degreaser, or solvent cleaning machine, which employed a popular and widely used solvent with great cleaning success. The reliable combination of a modern vapor degreaser and a trusted and effective solvent ensured the highest standards of cleanliness, critical for their Class 3, high-performance printed circuit boards.

Time for a change

However, towards the end of 2022, the solvent manufacturer abruptly announced they were discontinuing their popular cleaning fluid, taking the PCB manufacturer completely by surprise. The impending challenge of identifying a suitable replacement while maintaining their stringent cleanliness standards loomed large.

Fortunately, the company turned to a dependable vapor degreasing fluid supplier for support. They found a supplier that had expertise in not only cleaning fluids, but also the vapor degreasing process and equipment. This ensured they would get not only a replacement fluid, but also someone who could provide relevant technical support, effective troubleshooting if something went wrong and comprehensive training on using the new replacement cleaning fluid. The fluid supplier they chose also had a laboratory to conduct cleaning tests to confirm the replacement fluid was working properly. After conducting a cleaning audit for the PCB manufacturer, weighing factors such as their sources of PCB contamination and their vapor degreasing machine properties, the supplier recommended a promising fluid alternative.

The replacement cleaning fluid was a non-flammable, environmentally responsible solvent. It boasted a low GWP (Global Warming Potential), zero ODP (Ozone Depleting Potential) and was not an HAP (Hazardous Air Pollutant). Even better, it could be replaced, after emptying and cleaning the existing vapor degreaser, without any major modifications to the equipment. This meant the impact on the manufacturer’s production schedules would be low.

Tried and tested

After approving the recommended replacement cleaning fluid, the PCB manufacturer embarked on cleaning trials, to verify the efficacy of the new cleaning fluid. They provided sample PCBs that were cleaned at the fluid suppliers test lab facility. The results were impressive – the trial PCBs returned immaculately clean without a trace of flux residue or damage to their circuit board components or substrate.

The PCB manufacturer went on to conduct their own in-house testing. Their testing revealed the exact same cleaning results. The new fluid seamlessly integrated with their vapor degreasing machine and performed without a hitch. The results were nothing short of remarkable for the PCB manufacturer. They maintained their stringent cleanliness standards, which were always their primary objective.

Lessons learned – committing to the long term

The PCB fabricator, drawing from their experience with a discontinued cleaning fluid, prioritized long-term availability and sustainability when selecting a replacement vapor degreasing fluid. They were determined to avoid finding themselves without a viable solution in the future. Consequently, they opted for a replacement vapor degreasing fluid with a well-established history for both its efficacy and environmental responsibility. They avoided newly launched fluids due to concerns that these might have a brief shelf-life before facing discontinuation as well.

Navigating change

This PCB manufacturer’s journey underscores the power of innovation, flexibility, and collaboration. In their transition to the new cleaning fluid, they continued to deliver high-quality products using environmentally responsible cleaning processes.

In the ever-evolving landscape of vapor degreasing cleaning fluids, this PCB manufacturer’s experience serves as an example for PCB fabricators facing similar transitions. It emphasises the importance of careful planning, meticulous testing and choosing the right partners to ensure a smooth and successful transition to new vapor degreasing fluids. With the right approach and support, PCB manufacturers can navigate this challenge and continue delivering high quality products while minimising production disruptions and their environmental impact.