A paradigm shift in OLED illuminated labels industry

In the dynamic landscape of retail stores, bars, clubs, and seasonal markets, the need for effective product visibility becomes even more evident.

Illumination technologies are amongst the highly effective means for brand distinction and impactful visual communication.

As consumer awareness around sustainability continues to grow, conventional electronics integration in product packaging faces criticism due to concerns about electronic waste and its environmental impact. Commercialisation of printed and hybrid electronics provided the alternative solution offering the potential to minimising electronic waste.

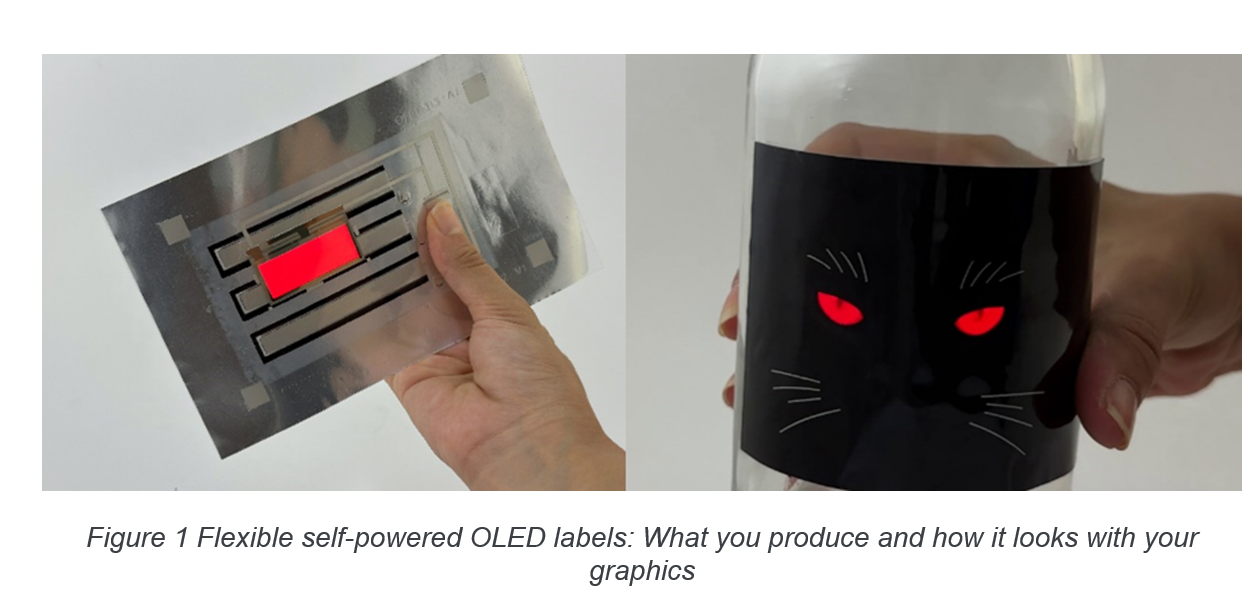

Hybrid and printed electronics use various light technologies and easily integrate into different package forms and in-store marketing tools. Within this context, there is a huge demand for thin flexible labels with preferred OLED lighting technology. Brand managers, package designers, and developers face the challenge of seamlessly integrating OLED illumination into the visual language of products, particularly for bottles’ flexible labels.

Years of effective market adoption of the Saralon technology platform SaralLight with LED, EL, or OLED embedded illumination approaches, brought them to the point to evaluate today’s market readiness enough for taking a step back and embracing the broader industry view. This perspective led to the creation of a new set of Saral Inks: SaralOLED Label Ink set. With this novel ink set and know-how transfer, Saralon empower printing and packaging industry to produce self-powered flexible labels with embedded OLED in-house.

The appeal of OLED labels for in-store marketers and packaging innovators

Designed to facilitate the creation of flexible OLED-embedded labels, SaralOLED Label Ink set aligns perfectly with market needs, forging a path towards efficient and interactive visual communication.

Organic Light Emitting Diode (OLED) is super eco-friendly. And recent technological advancements made it possible to produce OLED pixels in a very thin and lightweight structure on plastic substrates that make them ideal for flexible labels illumination. This sets OLED apart from the more common LED illuminated hybrid electronics. LEDs offer cool colour variations, high efficiency, and brightness but leave limited space for flexibility. LEDs are point light sources with relatively bulky structure.

However, the production process of flexible OLEDs has remained complex. Some small-scale printing is being conducted at universities or research centres under certain circumstances, but mass production technology using regular printing machines is still not available. Market-ready flexible OLEDs are currently produced using highly sophisticated vacuum deposit technology that makes them relatively expensive to produce and use.

Having said that, a distinct pattern of increasing market demand for OLED embedded illuminated labels for in-store marketing is evidently traceable. Saralon are presenting SaralOLED Label Ink set to assist packaging developers and printing firms in addressing this growing market demand.

Simplifying the tech: A closer look

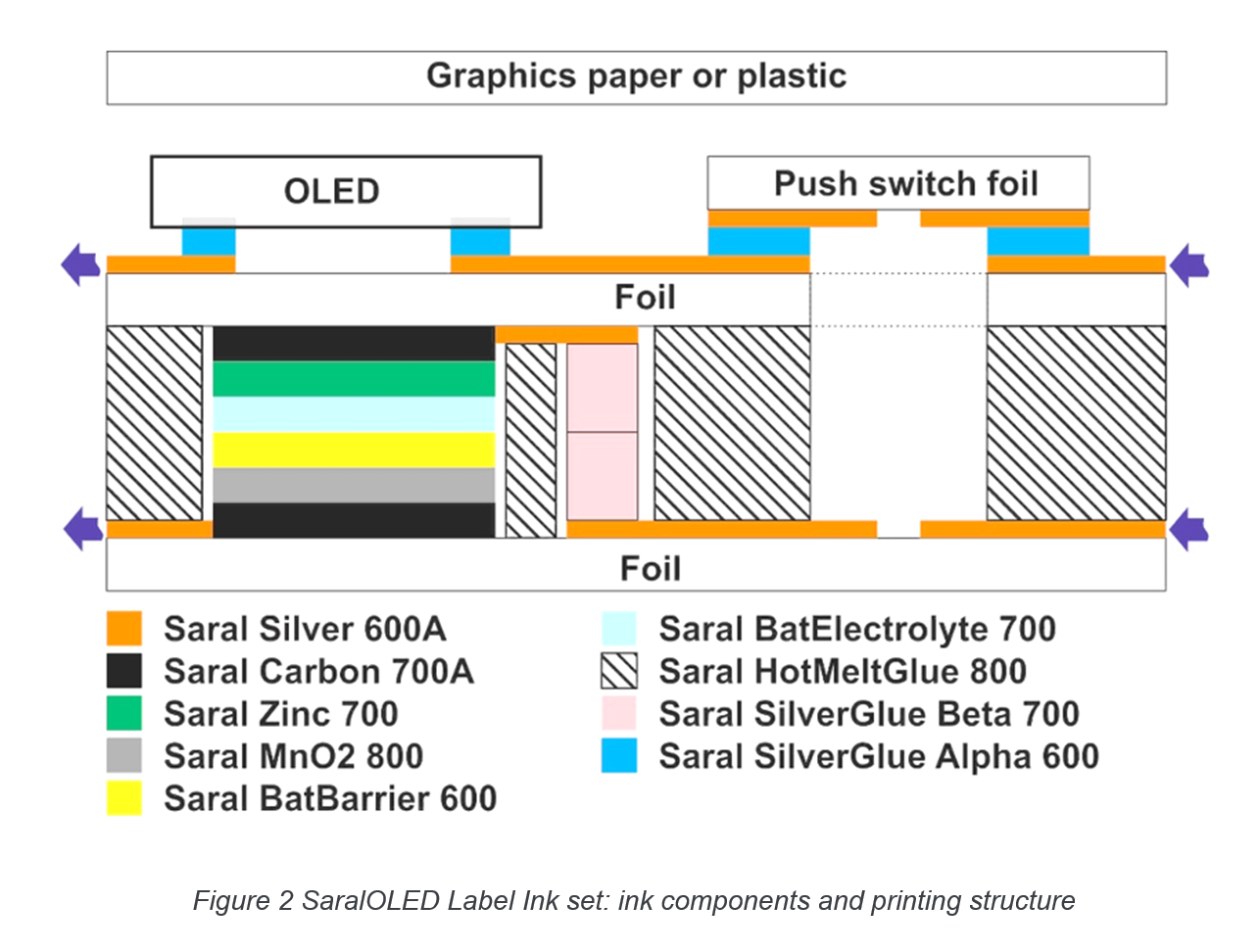

Figure 2 is a graphical representation of the OLED embedded structure. This simplified overview is meant to break down the printed ink layers in a concise yet insightful manner.

The development of this novel ink set was only possible through a handful of key technology enablers:

Autonomous energy – producing functionality by SaralBattery Inks:

With a focus on production scalability, design flexibility, and technological affordability, SaralBattery Inks has been developed for easy customisation and screen-printing of batteries on lightweight recyclable substrates as an integrated part of the electronic circuit.

Unlike market-available ready-to-use printed batteries on plastic, these inks work on biodegradable materials like paper too, enabling the creation of sustainable batteries.

SaralBattery Inks set consists of seven inks that can be printed in series connection to increase voltage allowing customised solutions. Notably, the ink set features a specially designed layer between the anode and cathode, eliminating the need for a separate paper-placement process. This printed layer acts as an electronic insulator while being ionically conductive.

Contribution of SaralBattery Inks as a part of SaralOLED Label Ink set means that there will be absolutely no need for the attachment of external batteries to the label. Instead, the power source will be printed as an integrated part of the production process. The produced label will keep self-powered functionality for several years.

Compact and stable structure using printable Saral Adhesive Inks:

In SaralOLED Label Ink set, the company has included three different adhesive inks with distinctive functionalities:

- Saral HotMeltGlue 800: Its main function is to laminate the cathode and anode sides of the printed battery. The key advantage of this ink is that it works when heated above 100°C. As the glue is not active in room temperature, after printing and drying, the printed sheets can be stacked on top of each other. This adhesive ink is solvent based, thermally dried, and similar to all other components of SaralOLED Label Ink set, simply screen printable.

- Saral SilverGlue Alpha 600: This ink is specifically developed to easily attach SMD components and in this case, the OLED pixel to the label. Saral SilverGlue Alpha 600 is a two components silver based conducting glue that requires low temperature curing (110°C), suitable for paper, plastic, and glass.

- Saral Silver Glue Beta 700: It is a specially designed anisotropic silver-based glue to electrically interconnect two substrates. This functional adhesive ink is heat activated and suitable for both paper and plastic.

Swift and reliable production facilitated by an all-in-one ink set:

Saralon’s mission is to simplify printed electronics through InkTech. Given that, we always consider the challenges and obstacles that printers may encounter during the production process and commercialisation of technology.

SaralOLED Label Ink Set is designed to ensure easy and successful production practice of self-powered OLED embedded labels on thin and flexible substrates insomuch as:

- It is a complete set of functional inks that work in the most harmonious and efficient way. Therefore, printers do not need investing extra time and cost to find compatible inks for various circuit parts. We’ve made it easy by providing this all-in-one set of inks.

- It is InkTech in the sense that Saral Inks always come with design files, printing guide, and professional technical support.

- There exists a starter kit that includes all necessary inks in the minimum possible quantity and technical details for the printers, convertors, and innovative electronics developers to have their own experiments and trials before ultimate decision making.