Phase change materials: Innovations in thermal management

Thermal Interface Materials (TIMs) are used in electronics applications to improve the efficiency of heat transfer and reduce the operating temperature of a device. They work by improving the conduction of heat through to a heat sink, where the heat is radiated to the surrounding environment by means of convection. Demand for improved thermal management in electronic devices is ever-increasing, particularly in applications where both miniaturisation and high performance are required in one package.

A new generation of thermal Phase Change Materials (PCMs) have been developed by Ben Han of Electrolube China (Suzhou) providing practical and effective alternatives to more traditional thermal management solutions, such as non-curing thermal pastes or greases.

A PCM is designed to alter its state at the phase change temperature, meaning that it will transition from a solid material to a softer, conformable interface above the phase change temperature. This allows the product to adapt to the contours of the surface, filling in all voids and small gaps, just like a paste would do on application, allowing for minimal bond line thickness and minimal thermal resistance at the interface.

Enhancing Heat Transfer

Typical applications that will benefit from enhanced heat transfer efficiency include technologies used in smaller electronic devices, such as mobile smart phones, gaming consoles, tablets, etc. These small devices perform many tasks at exceptional speeds and require increased power in order to do so. The size of the device means that the heat generated by the increase in power will have a negative effect on the performance and/or longevity of the device itself. Another significant area that relies on optimum thermal management includes power electronics, which are widely used in applications such as power distribution, sensor technology, electric vehicles and high-powered LEDs, to name just a few. Selecting the correct TIM for these applications is crucial to the long-term reliability of devices.

The initial selection of suitable TIMs for testing is often conducted on the basis of high bulk thermal conductivity, indicating the efficiency of heat transfer through the TIM itself. However, bulk thermal conductivity alone, could give a false impression of the expected performance. When tests are conducted under application conditions, low thermal resistance of the device indicates the true heat transfer efficiency of the TIM and can be understood using the following formula:

Total Thermal Resistance of a Device = (BLT/K) + Rc

BLT = Bond Line Thickness of TIM

K = Bulk Thermal Conductivity of TIM

Rc = Total Thermal Contact Resistance at the Interfaces

This formula proves that the bulk thermal conductivity is important but only in conjunction with the thickness of the TIM applied and the uniformity of the TIM across the interface surfaces. The formula also highlights why thermal pastes have continued to be a popular choice, offering good wetting of the contact surfaces for low contact resistance, whilst also offering minimal bond line thickness, addressing the surface roughness of the mating interfaces. However, PCMs have been introduced to provide similar performance to thermal pastes in these areas, whilst also improving on issues, such as the effects of pump-out and thermal stability over time.

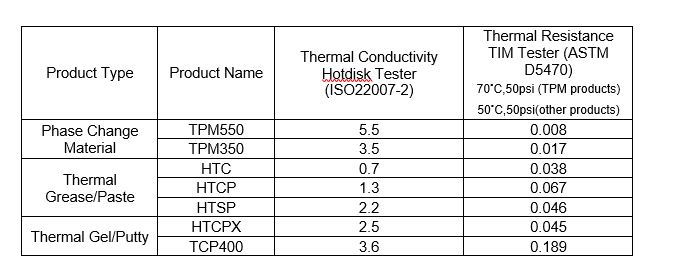

The table below shows typical conductivity and resistance values of thermal pastes and gels, compared to PCMs, from Electrolube’s thermal management range:

Pump-out

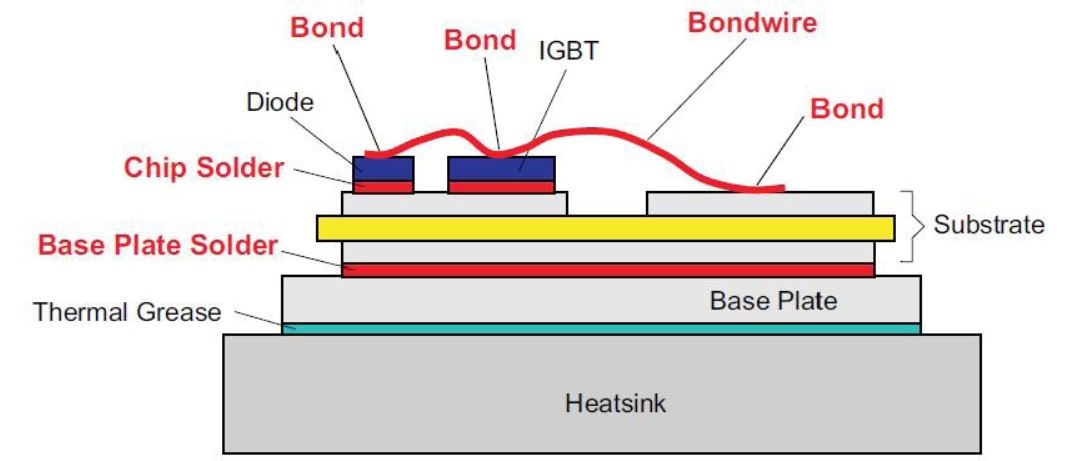

IGBTs are widely used in power electronics and provide a good example for understanding the effects of pump-out. They consist of a thermal stack, which includes materials of differing thermal expansion coefficients (CTEs) and a variety of bulk thermal conductivities, leading to temperature gradients throughout the IGBT.

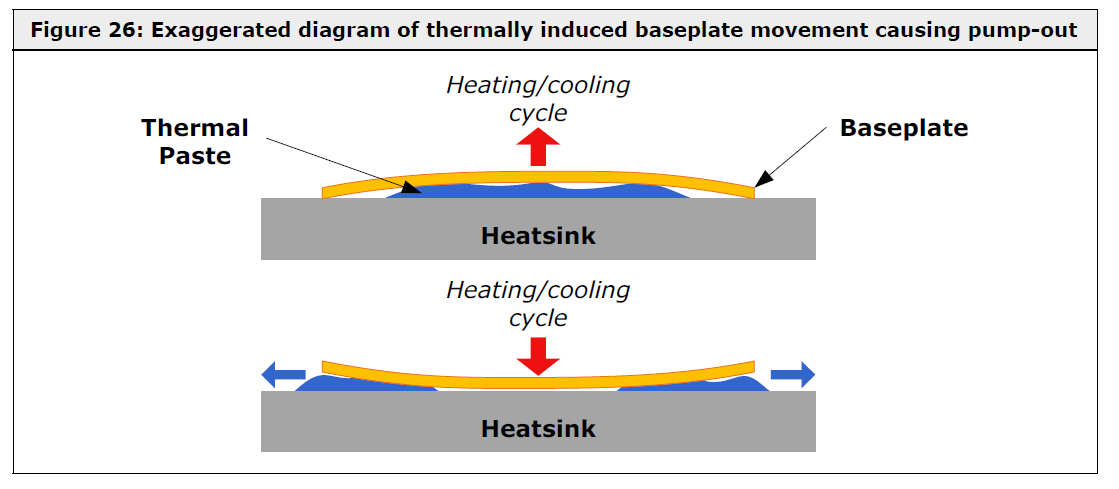

IGBTs and most devices in general will go through some form of thermal cycle, even if it’s as simple as switching the device on and off. When changes in temperature occur, all materials in the unit will expand or contract to a certain degree, depending upon the temperature the device reaches in operation and, ultimately, the temperatures that the individual components reach. The coefficient of thermal expansion will vary from component to component and so contraction and expansion can happen at different rates, with adverse effects such as pump-out occurring as a result.

When tackling issues with pump-out, it is important to understand the conditions and materials involved. Pump-out happens at the interface between mating substrates moving relative to one another during temperature changes. This results in a shear type action at the surface that can lead to changes in the rheology of the interface material and movement of that material from its original application position. PCMs alter their state above and below the phase-change temperature, so they are able to resist the effects of pump-out and remain more stable over many thermal cycles.

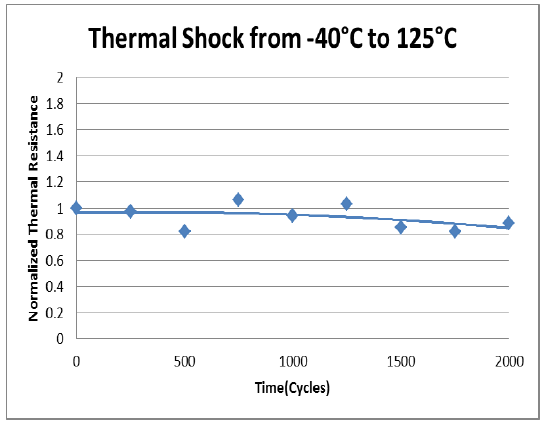

TPM550 – Thermal Resistance after Thermal Cycling

Other testing

Power cycles also result in temperature changes of the device and in turn, the interface temperature. Powered devices also exhibit their own thermal cycle during use, which can be further exacerbated by external environmental conditions. Whatever the reason, thermal changes will result in some form of pump-out effect and so the stability of the chosen TIM under end-use conditions is critical to evaluate.

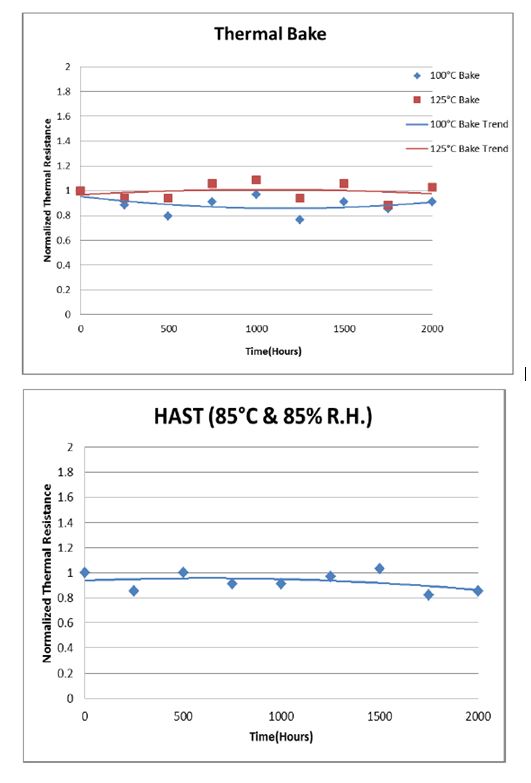

As the application requirements govern the expected environmental conditions, it is typical to see a range of testing conducted in line with the application, rather than a standard set of conditions. Such testing is usually conducted within similar frameworks, illustrating the thermal stability of the TIM after temperature cycling, high temperature bake and HAST (highly accelerated stress testing), and utilise thermal resistance values as an indication of stability. As can be seen from the graphs below, this accelerated testing provides a greater understanding of the lifetime of a TIM when compared to standard power cycle tests conducted under the exact conditions of use.

The Importance of Stability

The stability of TIMs can be thought of as a visual test, simply put, has the product stayed in place following the test programme? If an interface material moves during a thermal test, either through pump-out or via the effects of gravity in a vertical orientation, it is likely that the performance of the product will also alter. Simple tests can include applying the product between two substrates and evaluating any movement or separation of the material during thermal shock testing. This easy test can highlight the importance of application of a thermal interface material, particularly in the case of thermal greases. These non-curing products are designed to be applied in thin films of around 50-100 microns but are often used at much higher thicknesses, which can result in the pastes separating or moving relatively easily once the shearing action of pump-out occurs, and the overall efficiency of heat transfer is reduced. A phase change material is not affected in the same way by pump-out and shows greater physical stability than thermal greases.

In the wider context of TIM choice and material stability, it is important to mention what alternative approaches a user might consider. Electrolube has introduced some novel products that offer the benefits of traditional thermal management solutions while combining the stability required for high thermal cycling applications. These offer a surface cure only and form a stable compound that can be easily removed if rework is required. Other traditional products that provide a complete cure with a high level of stability include single-part silicones or two-part epoxies, however, rework is much more difficult with these products and they are unlikely to achieve the low thermal resistance of a traditional thermal paste.

Regardless of what the thermal interface material looks like after these tests, the most crucial point is if the thermal resistance at the interface has remained low and consistent, as this is the primary factor that is going to affect the performance of the device.

PCMs have shown consistent thermal resistance when used as an interface material under a range of conditions, and are therefore chosen for their stability and capacity to maintain a low thermal resistance. But why do they perform so much better under these challenging conditions than a traditional thermal paste?

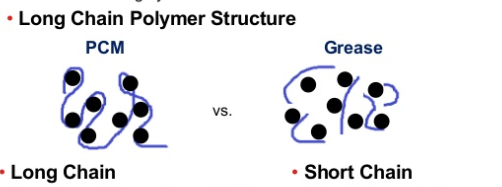

A phase change material alters its state from a solid to a softer material above a set temperature, usually around the 50˚C range. This function is achieved by using a polymeric material, rather than a base oil, as the basis of the TIM formulation. The polymer chains provide enhanced stability of thermal filler dispersion during both the solid and softened state. This results in enhanced thermal conductivity and long-term, low thermal resistances, as the material is kept in a more consistent state throughout its lifetime in the device. Thermal pastes on the other hand, are comprised of base oils with shorter molecular chains offering excellent wetting for initial application but possibly leading to issues including pump-out, drying out and oil bleeding over time.

Another important property of PCMs is their ability to store and release energy as the change of state occurs. This results in some thermal absorption and protects the device from sudden spikes in temperature due to rapid changes of power, for example.

When considering which application is appropriate for a PCM, it is essential to have a proper understanding of the temperatures and temperature profiles that the device will be subjected to during operation. For example, while a device subject to thermal cycling or operation at a continually stable temperature will dictate what type of TIM is likely to achieve the most efficient performance, with PCMs there is the additional factor of the phase change temperature to consider. If the continuous operating temperature of the device is below the phase change temperature, the product will not perform at the level normally expected of it.

New Product Introductions

Electrolube recently added two new thermally conductive PCMs, TPM350 and TPM550, to its thermal management portfolio. TPM350 has a thermal conductivity of 3.5W/m.K and becomes workable at approximately 50°C. At this 'softening' temperature it changes state to become a more conformable material, minimising thermal resistance at the interface and improving thermal transfer. Once it cools, it reverts back to its original state. The material’s advanced formulation ensures minimal contact thermal resistance.

TPM550 has a higher thermal conductivity of 5.5W/m.K and has a softening temperature of 45˚C. In common with TPM350, TPM550 produces no mess due to its thixotropic characteristics, which prevents flow outside of defined interfaces. Both PCMs can be reworked and more applications can be served per kilogram of the materials, reducing production costs.

These new PCMsare silicone-free, have an operating temperature range of -40 to +125˚C and are RoHScompliant. Both TPM350 and TPM550 are screen printable and, while they do contain small amounts of solvent to improve wettability on application, this rapidly evaporates following application to leave the solid phase change material on the substrate.

Conclusion

PCMs, once heated above their phase change temperature, become highly thixotropic liquids that perform as well as - and sometimes even better than – a traditional thermal grease. Moreover, their low phase change temperature ensures low thermal resistance over a wide temperature range, safeguarding minimal bond line thickness with improved stability and pump-out resistance. The application methods of PCMs for high volume production mean that most can be utilised in existing production processes with minimal, if any, changes, whilst also allowing for easy rework, offering many of the same benefits of traditional thermal pastes. As they offer greater long-term stability compared with thermal greases, they are better suited to thermally challenging applications where product life expectancy and reliability may be critical; such as automotive electronics or remotely located wind power inverters, for example. Traditional thermal pastes/greases will continue to be a popular choice, although for some applications, especially those requiring greater long-term stability, a phase change material is likely to win over the crowd.