Increased efficiency in the production of loudspeakers

The loudspeaker market is booming. In addition to an outstanding product, efficient production is crucial for a company to stay in front of competitors. Adhesives play an important part in this, but the potential they offer for increasing productivity is not yet fully exploited.

By Dr. Gunter Witek, Product Manager, DELO Industrial Adhesives.

Sound has become a lifestyle element, making a high-quality sound experience more and more important. Apart from the home entertainment market for conventional speakers, Bluetooth speakers and surround systems, there are two other important market segments: the smaller one includes speakers used in planes; the significantly larger segment covers automotive loudspeakers.

In 2000, cars contained on average four loudspeakers and two tweeters, while today they are equipped with nearly 20 speakers. Whether parking sensors, eCall, e-sound, powertrain sound or exhaust systems - they all have their own speakers, not to mention the sound systems of constantly improving quality. Given the annual production of more than 75m cars, this is a lucrative but highly competitive market.

Manufacturers primarily distinguish themselves through technical innovations for an even better sound experience, a more attractive design and longer service life. The wide range of material combinations and the high requirements for the various components reveal the importance of adhesives in striving for highest quality and reliability, since, after all, a typical loudspeaker is bonded at seven points at least.

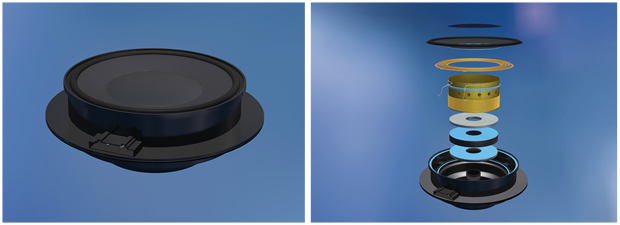

An automotive loudspeaker shown fully assembled and in exploded view

Required performance of adhesives

While high strength, full transparency, electrical conductivity or good sealing performance are usually among the most important properties of adhesives, it is the sound that counts when it comes to loudspeakers. Their sound quality can be improved by adjusting the flexibility of adhesives in a way to provide optimal vibration damping, especially for the speaker's movable parts. Both flexibility and strength are needed to protect speakers from damage caused by impact, shock or strong vibrations.

Furthermore, it is important that the adhesive's properties do not degrade during ageing, although requirements vary depending on the industrial sector. Highest demands are placed on products used in the automobile industry, since components in cars need to withstand variations in temperature, vibrations and humidity. Speakers installed in car doors, for example, are frequently exposed to slight moisture from rain penetrating between window and rubber seal into the interior door panel.

But even such established, high-volume manufacturing processes still leave room for improvement of productivity. That is why we are going to examine some bonding areas and suitable adhesives.

Spider to voice coil

This bond connects the spider to the voice coil, also known as bobbin, which is usually made of paper or polyimide-coated and has wires wrapped around it. The spider is responsible for keeping the voice coil moving up and down in the centre of the magnetic gap, causing the membrane to vibrate and create sound waves. While cyanoacrylate-based superglues are still widely used for this application in industrial processes, loudspeaker manufacturers could significantly increase production efficiency by using UV and light-curing acrylates. Adhesives of this group are cured under high-energy light in just a few seconds.

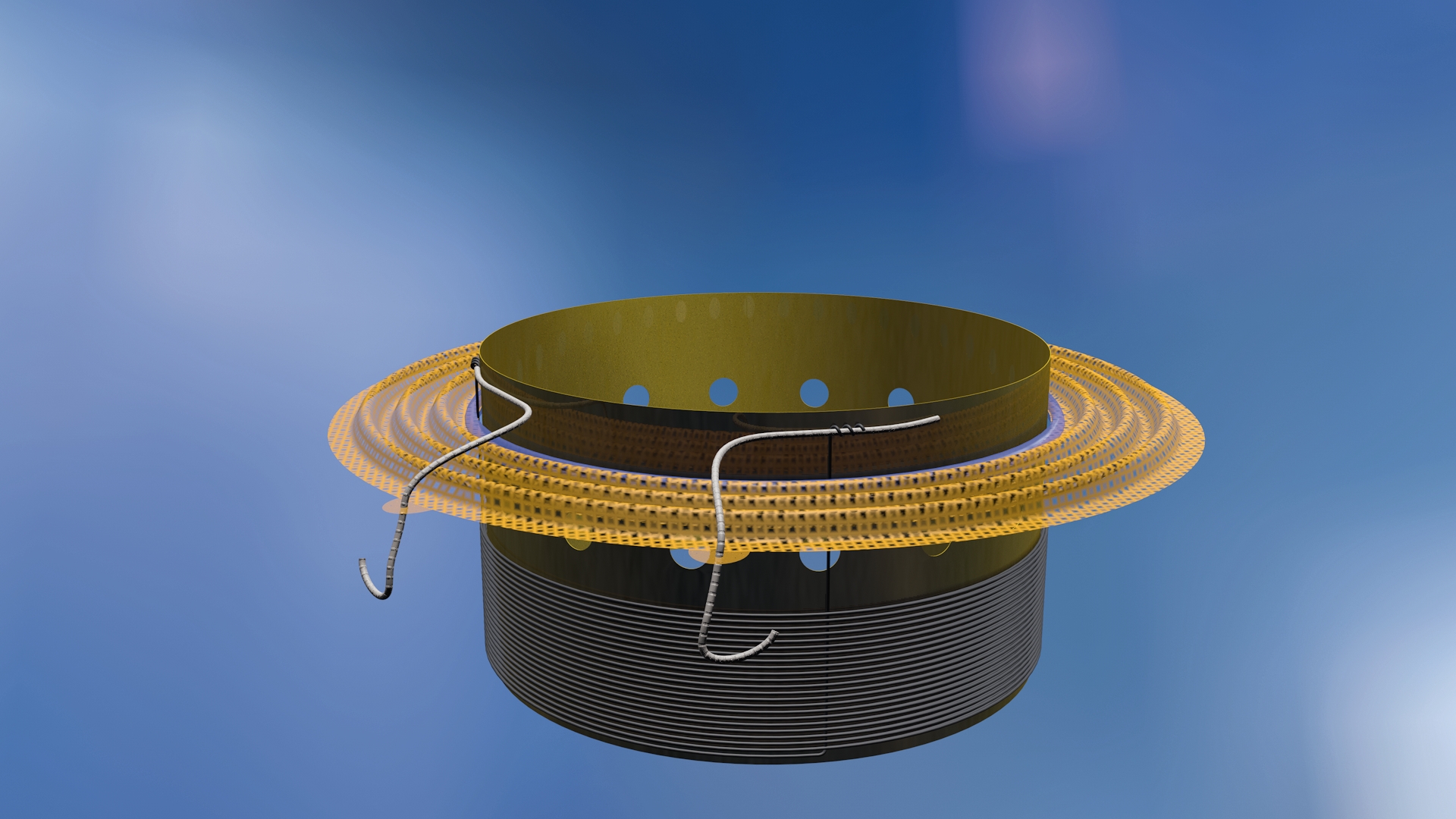

Light-curing allows making short work of spider-to-voice coil bonding

In the case of the spider, the highly absorbent polycotton material makes this process more difficult, but thanks to high-intensity spot lamps sufficiently intense light penetrates through the fabric, allowing the adhesive to achieve its final strength within 10s. In addition, specially developed acrylates provide thermal stability up to +150°C. Such temperatures arise from energising the voice coil and are too great an obstacle for many standard adhesives and superglues to overcome.

Spider to basket

This application as well holds potential for efficiency improvement. Some manufacturers use 1C polyurethanes which are slowly cross-linked by the action of air humidity, forcing manufacturers to stock large quantities of these assemblies. Here again, light-curing acrylates can be integrated in the process, with cycle times of up to 10s.

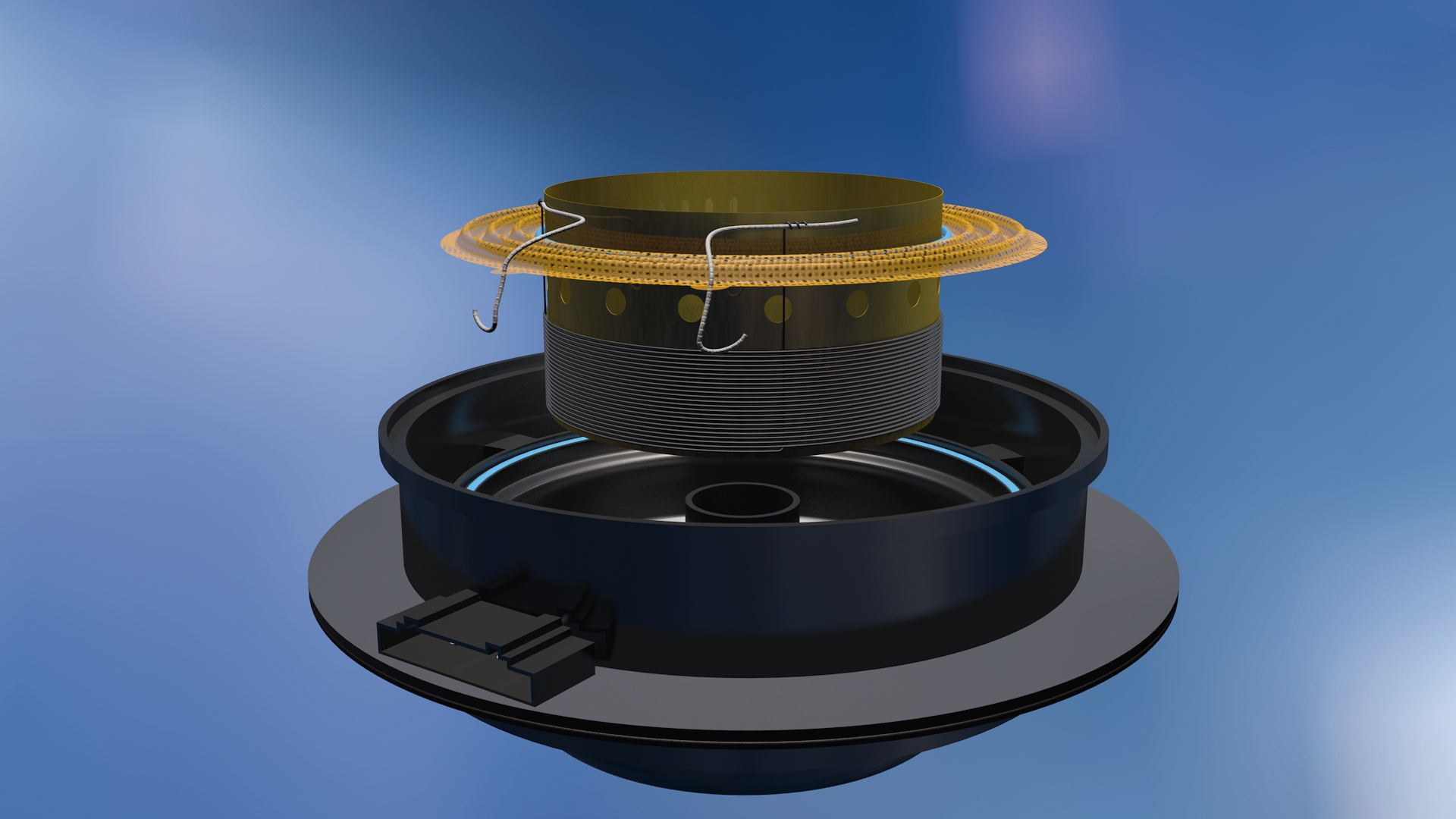

Spider-to-basket bonding

Furthermore, since the spider is deflected and bent upward, a high peel resistance of the adhesive is advantageous. Suitable products reach values of more than 20N/cm. As is common with light-curing acrylates, the adhesive can be coloured for application and quality control by fluorescence, taking place directly after dispensing.

Membrane to voice coil

Connecting the membrane to the voice coil is a third application to benefit from light curing, depending on the order of the process steps. A high peel resistance is important here as well for vibration compensation when sound is created. Depending on the adhesive used, maximum cycle times of 8s are even possible.

A membrane, of a tweeter in this case, is glued to the voice coil

This bonding area is particularly demanding in matters of acoustic performance. A requirement that can be met by using adhesives specially developed for the loudspeaker market. Their viscosity and flow properties ensure optimal wetting and act like a mechanical fastener.

Bonding the magnet

In view of the required impact resistance and the desired fast-curing properties, adhesives used for bonding the magnet system also need to meet certain criteria. Light-curing adhesives are not suitable, since light cannot be transmitted through the metal. Two-component methyl methacrylates in no-mix systems are therefore mainly used in this case. In this process, an activator is applied to one of the two components and the resin to the other one. Cross-linking starts when the components are joined. After five minutes, the process reaches a stage allowing further bonding of the assembly. Methyl methacrylates achieve good values in typical reliability tests such as the drop test or storage at a temperature of 40°C and a humidity of 93%.

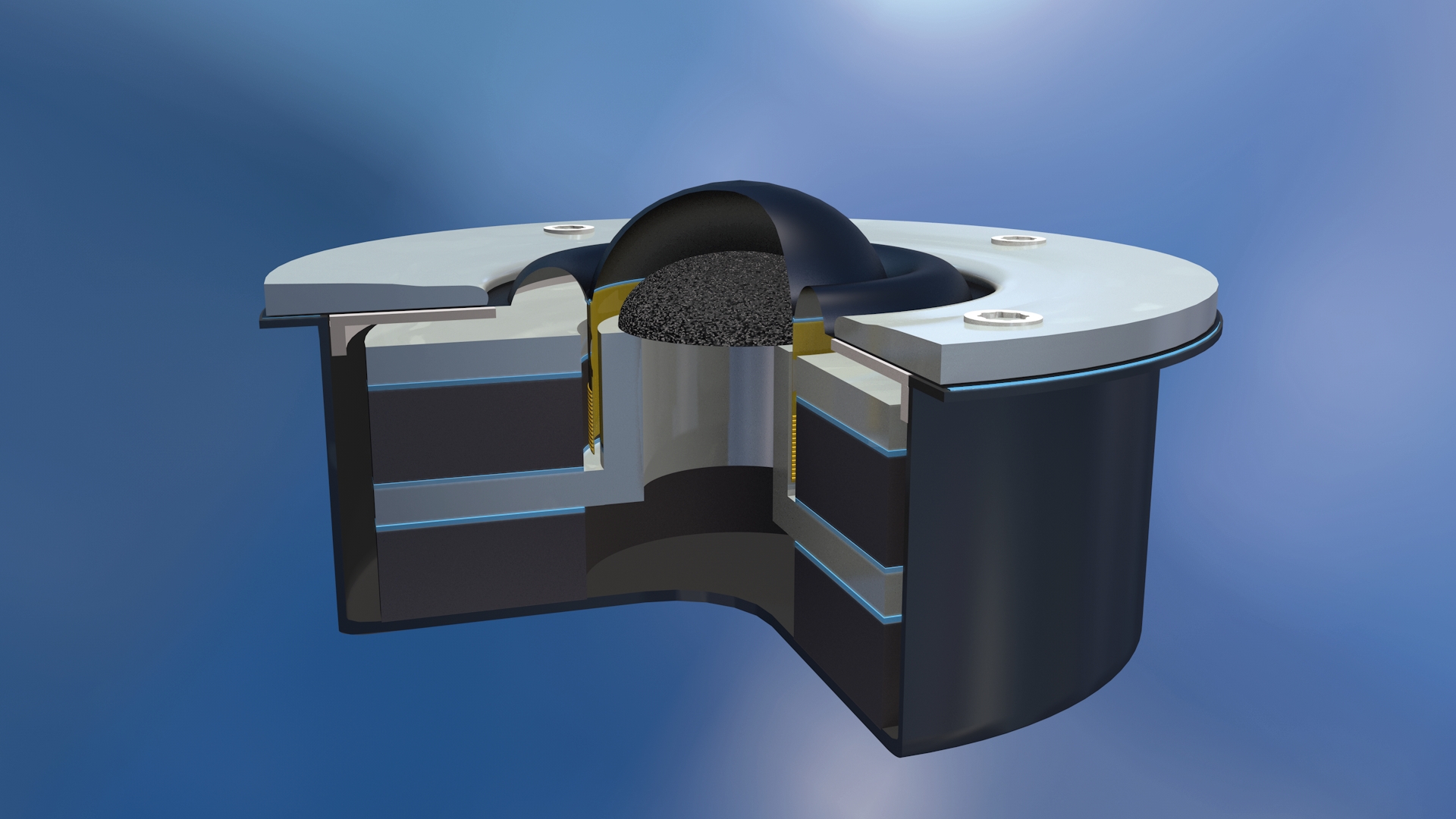

and yoke (bottom) are bonded to a magnet.jpg)

Pole piece (top) and yoke (bottom) are bonded to a magnet

To accelerate this process, manufacturers should consider anaerobic adhesives that can be prefixed by light. This would only require a slightly thicker fillet, where the adhesive would cure within seconds to such an extent that processing can be continued. Final strength would then be reached after 24 hours under exclusion of oxygen.

Other less challenging applications

Loudspeaker bonding involves some more applications that are less challenging or leave little room for enhancing productivity. One of these applications is the membrane-to-basket connection. Cyanoacrylate-based adhesives provide sufficient strength for this type of bonding and cure at room temperature and a relative humidity of 40 to 80% within 8-15s. Given the larger quantities of adhesive and larger needle diameters, the risk of clogging is reduced compared to more miniaturised applications.

Conclusion

Loudspeakers are manufactured in an established and elaborate production process. However, optimisation is still possible, especially by using UV acrylates. The properties of these adhesives can be adjusted to meet acoustic requirements and their fluorescence allows inline quality, thus decisively contributing to a long-lasting high quality of loudspeakers. In addition, they allow manufacturers to significantly increase production efficiency and, consequently, provide a competitive advantage.