In-mould electronics become commercial once again

Conductive inks are a wonderfully adaptive technology, this characteristic has enabled them to stay relevant and to rejuvenate themselves over the past several decades, as old markets have struggled or declined the technology has managed to find new uses. Several years ago, a new frontier called in-mold electronics (IME) started to emerge, this frontier is once again becoming commercial.

Author: Dr Khasha Ghaffarzadeh, Research Director, IDTechEx

IME is not a product but is a process. Functional and graphical printing is carried out on a 2D flat substrate which is then formed and moulded into a 3D shape. As such, it provides a way to structurally integrate the electronics into 3D shaped objects whilst using high throughput production processes suited to volume applications.

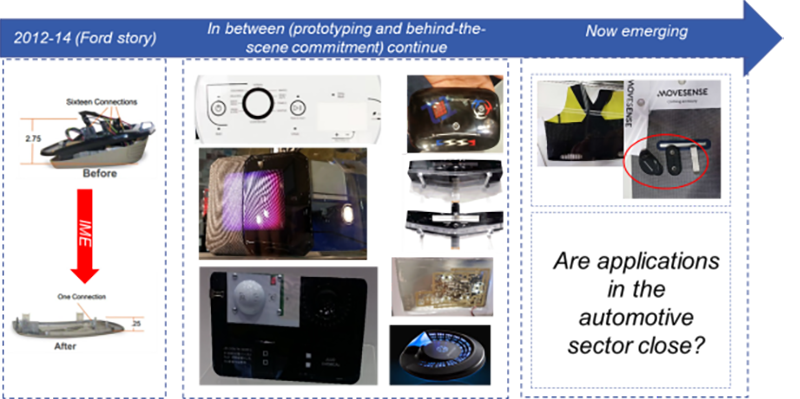

The first successful product was launched in a Ford car in 2012. Here, using IME, the overhead console had been made thin and light. However, the product was soon recalled. We understood that the overhead console gave false read-outs. This failure put the industry back and caused uses to be extra cautious.

Despite this, many prototypes were developed. These include prototypes for use in consumer electronics, whitegoods/home appliances and automotive applications. Our visits to end user sites confirmed that there were active engagements behind the scene. In this time, the technology also became more known. Many material suppliers appeared, pushing the technology and seeding the market. The IME houses also became more active, helping users do prototypes and pilot studies.

Products made with IME are once again on the market and soon, we expect to see bigger announcements in industries such as in automotive. The market, therefore, has overcome its past failure and turned a page.

IME is made possible thanks to the adaptability of conductive ink technology. Here, the formulations and filler compositions must be adjusted to withstand a major one-off elongation event during the forming, and to survive the thermoforming and moulding conditions.

The interest on the part of ink suppliers has increased over the past few years. This is in line with the interest in stretchable conductive inks. Today many paste makers have either already launched a product or have demonstrated the capability to serve the market.

The competition therefore is intensifying and as such we expect that premium pricing will not hold over the long run. This is not to say that there is no room for differentiation on service or performance. In terms of the service, the ability to work with customers closely and customise solutions for specific use cases is highly valued. This is because established figures of merit do not yet exist to enable offering commodity-like standardised products. In terms of performance, not all the inks are the same. Some users tell us that, for example, some pastes are superior in terms of handling sharp bends whilst some offer better adhesion.

Furthermore, suppliers must now take a total solution approach. As such, they are now offering a full portfolio of IME compatible materials. This is an asset because the supplier becomes a one-stop-shop, because it eases the development burden on the user, and allows the suppliers to aggressively price elements of the portfolio where competition is rife whilst making higher margins in other parts.

To learn more refer to Conductive Ink Markets 2018-2028: Forecasts, Technologies, Players here.