EPD Coatings Market to cross $20bn by 2025

According to a new research report by Global Market Insights, Electronic Protection Device Coatings Market size will surpass $20bn by 2025. Electronic protection device coatings are the polymers that are applied to printed circuit boards (PCB) in thin layers to electrically insulate and protect the components from environmental stresses such as moisture, chemicals, dust, and debris.

These coatings can be applied by various techniques which are majorly brushing, dipping, manual spraying or automatic spraying.

Electronic protection device coatings market is majorly driven by rise in use of portable electronics, increased demand from automotive electronics applications and decrease in size of printed circuit boards over the last few years.

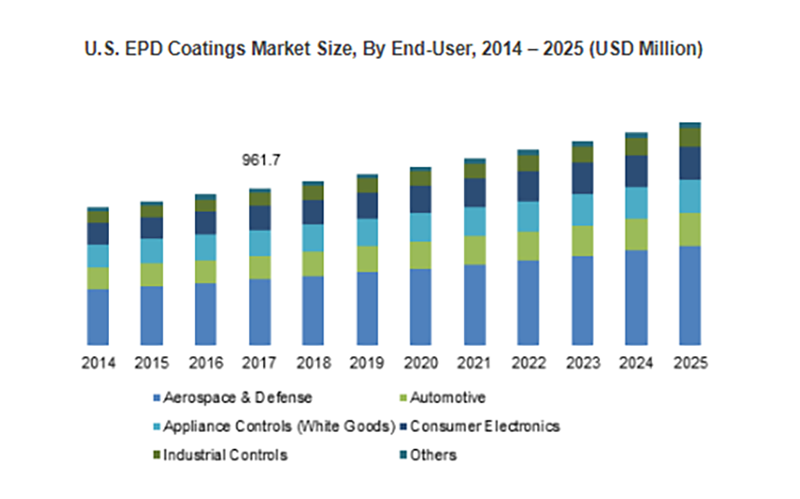

The market is expected to become more diverse in the forecast period as these coated electronic products are available in endless array of sizes and shapes ranging from complex panels, large motherboards, tiny PCB and flexible circuits. These coatings are used in various industries such as automotive, consumer electronics, medical, avionics, military, industrial machine controls, aerospace among others.

Electronic protection device coatings report considers various materials (chemistries) such as acrylic, silicone, polyurethane, epoxy and others (paraxylene, rubber, synthetic rubber, fluoropolymers). The choice of coating used depends upon the the application, operating temperature, curing time, moisture protection among others.

Acrylic is the most commonly used Electronic protection device coating material in the electronics protection industry (almost 70 to 75%) as it is available at a cheaper price as compared to other chemistries and have good environment protection properties. They are widely used for coatings PCB’s in consumer electronics, appliances and white goods industry.

Also, they have wide operating range and can adhere to wide range of substrates such as LED boards, electrical generators, relays, cell phones, avionics among others. The US acrylic coating market for electronic protection is $520m by end of forecast period driven by robust demand of computers, laptops and smartphones and other household electronics.

Polyurethane coating is another electronic protection device coating material, which offers excellent chemical resistant and protection in harsh environments. They also maintain flexibility at low temperatures and can be used on wise range of substrates such as PCB, electrical generators, fire alarm components, automotive electronics, motors, transformers among others.

The global polyurethane coatings market for electronic protection device is expected to reach almost $800m by 2025. Epoxy coating is another important type used for electronic protection such as electrical connectors, relays, marine industries, farming, mining among others. Epoxy coatings are very hard and are good at resisting moisture and have excellent chemical resistant.

Automotive is one of the fastest growing application for electronic protection device coatings market, as the market is primarily driven by increased demand for safety & comfort features, rise in luxury car sales especially in developing economies & rapid technological advancements which require heavy use of electronics.

It is estimated that by 2024, the global car market would reach more than 110 million worldwide driven by electrification in automotive industry especially innovation in electric and hybrid vehicles, recovery of European markets mainly Russia and Ukraine, steady demand from Asian countries especially India, Malaysia. Overall the demand of electronic protection device coatings is expected to grow by 4-5% each year till the forecast period in the automotive application.

Asia Pacific is the largest electronic protection device coatings market as almost 80-90% of PCB manufactured are made in China, Japan, South Korea, Taiwan, Singapore among others. Asia Pacific is forecasted to be the fastest growing market driven by increased demand of smart electronic appliances, steady demand of white goods and growing industrialisation. Also availability of low cost raw material & cheap skilled labour, global companies are shifting their attention to low cost countries such as Malaysia, Thailand, Vietnam among others to set up manufacturing base.

Key players present in the electronic protection device coatings are HB Fuller, Henkel, Dymax, Electrolube, Chase Electronics Coatings, 3M, Elantas, MG Chemicals etc.