Continuous improvement in surface-mount assembly and the pathway to smart manufacturing

Data structures and software tools developed to enable continuous improvement of surface-mount assembly productivity now create a stepping stone that can help OEms and CEMs make the transition into smart manufacturing. This comprehensive report from Yamaha Motor IM explains all.

Introduction: The Smart Imperative for Manufacturers

Smart manufacturing – the fourth industrial revolution, or Industry 4.0 – is all about leveraging advanced technologies to maximise productivity, quality and responsiveness, minimise waste, and meet market demands for rapid delivery and high levels of product individualisation. Only a smart infrastructure, with digital communications at its heart, is capable of networking and adapting continuously to meet these objectives.

This revolution is coming first in territories that must depend on advanced technology to maintain competitiveness, typically where labour costs are high and customer expectations are even higher. Manufacturing businesses planning capital investment must balance their short-term needs with the certainty that they must be ready for a future that will demand higher levels of intelligence, automation, and communication capabilities at every point to make the transition from value chain to value network.

The goal is to create value at all points in the network. On assembly lines, this calls for smart equipment that is capable of self-monitoring and self-analysing, and communicating status and decision-making information in real-time to supervisors and business managers. The traditional boundary between factory floor and back office is disappearing, as computing brings the power to convert manufacturing data into information that has value at multiple points throughout the organisation and among trusted partners. This industrial revolution will be the catalyst to unify all business activities into a seamless cohesive enterprise – from designing and making to marketing, selling, accounting, and directing.

The move to smart manufacturing is a major force driving the decisions of today’s manufacturing managers. It is typical now that any capital investment in the current timeframe is decided with a view to how it will support the company’s roadmap into smart manufacturing.

Industry 4.0 and Surface-Mount Assembly

Surface-mount electronic assembly is a prime example of the type of enterprise that is ready to go smart. Advanced technology and automation is driving a resurgence of activity in areas where labour costs have traditionally been highest, such as in Western Europe, North America and Japan. Businesses need to take the next step if they are to grow their market share and sustain profitability.

A typical surface-mount line may combine equipment such as dispenser or screen printer, mounters and optical inspection from a number of different manufacturers. Although the interfaces and protocols used to support communication between machines can take advantage of industry standards, the differences in the underlying data structures present a barrier to the rich information exchanges needed to support smart manufacturing. A full-line solution sourced from a single supplier, however, does not necessarily guarantee an easy solution. The way the data is organised is critical, and some manufacturers are able to demonstrate data structures that are well suited to making detailed information readily available to analytical software.

Yamaha Motor Intelligent Machines Division has devoted considerable resources over several product generations, to establish a protocol for real-time data exchanges between inline surface-mount equipment, and software capable of capturing and analysing the data. These capabilities are now critical to support smart manufacturing.

The Start of Smart?

Historically, surface-mount lines have been unable to capture useful information about the performance of processes such as solder paste printing or component placement, because there was no communication standard capable of supporting the detailed feedback needed to allow sharing of quality information.

To overcome the limitations of inline surface-mount equipment and unleash the power of data to drive continuous improvement, Yamaha developed its own machine-communication interfaces to facilitate the collection of rich data from machines in the production line, and to enable analysis and reporting or alerting in real time. This has helped manufacturers improve quality control and boost productivity by identifying defects such as missing components or incorrect alignment and taking remedial action immediately. Yamaha’s initiative also made it possible to collect information capable of driving predictive maintenance, which is also now seen as an important aspect of smart manufacturing.

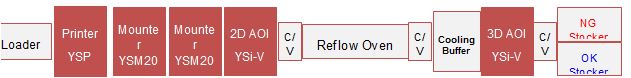

Figure 1. Surface-mount line with closed-loop feedback of post-mounter AOI data for real-time and historical analysis.

Figure 1 shows how feeding back optical inspection (AOI) data gathered inline immediately after component mounting enables diagnosis of any component-placement errors or solder-paste defects down to the level of individual mounter nozzles or stencil apertures. Software running on the machines is able to diagnose the exact causes of errors and send alerts to a mobile terminal such as the supervisor’s smartphone to help accelerate fault resolution and thereby minimise line stoppages. This mobile decision application is part of Yamaha’s proven Y.Fact software suite for optimising setup and performance at machine, line and factory level. Combined with the individual machine capabilities, this software provides a platform from which a smart manufacturing strategy can be launched and continuously extended and improved.

The four modules that comprise Y.Fact software, known as P-Tool, M-Tool, S-Tool and T-Tool, handle Data Programming, Line Monitoring, Setup Navigation and Traceability respectively. The P-Tool for data programming carries out actions such as CAD-data conversion and reverse engineering of gerber files where necessary, to help save preparation time. Eliminating trial runs fits well with smart manufacturing ideals by saving materials and supervisor time, as well as automatically optimising and balancing the line.

The line-monitoring capabilities of the M-Tool represent perhaps the most obvious area for software to support smart manufacturing. Displaying line and factory status via a web-based interface makes detailed information such as efficiency, operating ratios and pickup rates available to supervisors in real time. figure 2 shows how colour-coded status enables fast and easy monitoring of line status. It is an easy next-step to consolidate this data automatically into reports for storage and analysis by higher-level applications running in The Cloud.

Figure 2. The line-monitor display enables at-a-glance interpretation of complex equipment status.

By facilitating setup, the S-Tool utility helps manage materials that may otherwise deteriorate over time. Automatically monitoring stock age and condition, for example by observing time limitations on moisture-sensitive devices (MSD) and checking use-by dates of components or solder paste, helps exclude any unsuitable materials from finished products.

Connections to any Component Tower Storage system in cooperation with the machines’ parts-remaining counter helps minimise stoppages for reel and feeder changes and enables continuous non-stop operation if used to coordinate splicing of tapes. The tool records data such as the board code, solder paste type, and the identities of component feeders and reels, which can be collected by a handheld barcode reader. A topical example is recording barcode information such as brightness (BIN), colour temperature and illumination pattern of LEDs to block components with dissimilar characteristics from being used in the same assembly. This is a smart-ready capability that is directly applicable to one of the most important market opportunities for today’s electronics manufacturers.

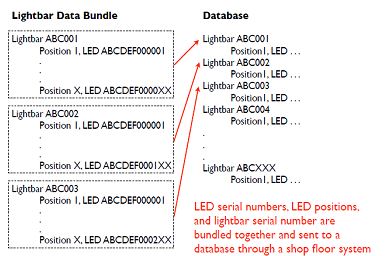

Taking a step beyond component checking during setup, the T-Tool supports traceability by recording each individual assembly identifier with its associated board identity and component data for every placement on the board. This is one area the underlying data structure of the surface-mount equipment is critical for handling the detailed component-level information. Yamaha’s proprietary data structure is able to record component serial numbers as well as position data and the PCB serial number and transfer the information through a shop-floor system into a traceability database (figure 3). This database can be queried for numerous purposes, such as tracking inventory and materials throughout the production flow to assist purchasing for just-in-time assembly, to help demonstrate conformity with customer requirements, or to verify the provenance of components.

Comparing traceability data with production test data can help to identify recurring problems with components or machinery. Ultimately, if delivered units are found to fail in the field, the ability to trace the serial numbers of components affected can guide troubleshooting and assist with product recall.

Figure 3. Data collected in real-time and stored in the traceability database can support activities ranging from customer relations to equipment maintenance or product design.

Ready for the Revolution

By collecting and exchanging rich data sets, and interfacing smoothly with analytical software tools that cover end-to-end the flow of delivering components and building assemblies on the factory floor, Yamaha’s intelligent surface-mount line supports the principles of smart manufacturing, which all industries are working towards:

- High quality, network-centric communication between humans and systems, in the entire value network including end users

- Digitisation of information and communication among all value chain partners and in the production process on all levels

- Granular, flexible, and intelligent manufacturing technologies, adjustable on the fly to meet highly specific end-user demands

Conclusion

Smart manufacturing is the future, and is widely regarded as the most effective way for businesses to deliver competitive products into global markets. The foundations for smart manufacturing, including inter-machine communication protocols, real-time monitoring and analytical tools, are already well established in parts of some industries such as surface-mount electronics assembly. Here, the transition to smart manufacturing is happening now, bringing improvements across the factory-floor. Ongoing adoption, harnessing the power of The Cloud, will deliver the advantages of smart throughout the enterprise.