Bonding technique features high tensile strength

A ceramic-to-ceramic bonding technique, suitable for use in demanding and high-pressure fluid handling and vacuum applications, has been released by Morgan. Using a preparatory formulation applied to one or both faces of the parts to be joined, the bonding technique delivers high tensile strength.

The process is suitable for bonding both porous and fully dense ceramics, making it suited for a variety of applications from fluid handling systems to diode pump lasers.

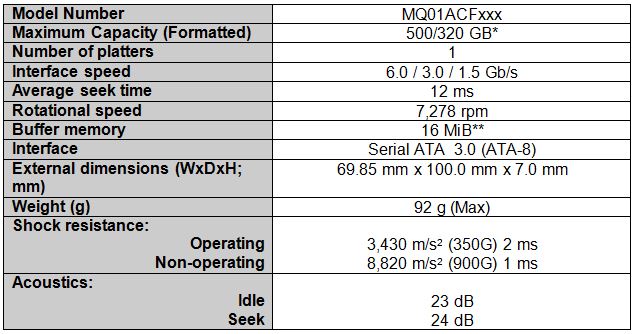

Internal testing of the new bonding technology has delivered impressive results, with a bond strength of 132MPa and a force to failure of 11,330kgf. Both of these figures represent a level of performance many times that of co-firing (7.7MPa and 577.97kgf in the same application) and adhesive bonding (5.4MPA and 460.33kgf). This data is summarised in the table below.

Suited to pressurised applications, the technique can be used in fluid handling assemblies requiring leak-tight joints. It can also provide a hermetic joint with vacuum levels down to 10-8mbar where electrical insulation or containment is required.

Internal pressure tests have shown that the joint can withstand pressures in excess of 25bar (design dependant). Tightly controlled tolerances and clearances allow Morgan’s engineers to design systems in which a captivated rotor using this bonding technology can operate in a high-pressure environment. Such design features and technology open new opportunities for applications where pressure differential principles are applied, such as desalination.

In other applications such as high power diode pump lasers (DPSS), the bonding technology offers the possibility to design hybrid components, for example, combining reflective porous ceramic with a dense ceramic material. In such a hybrid construction, high-reflectivity Sintox AL is bounded to Deranox 995. Sintox AL provides a good ‘scatter’ of the laser light thanks to its particle size which gives the material excellent microstructural control of defined porosity. The material provides a highly diffuse reflectance, behaving as a bulk reflector of the source of radiation by both reflecting and refracting light back into the cavity. Deranox 995 provides high strength and impervious properties for the cooling fluid. The high mechanical strength of the Deranox 995 provides the structural rigidity needed to mount the diode stack and at the same time machined cooling channels in the dense material allow the cooling media to operate without any contact with the diode stacks.

Yannick Galais, Morgan explained: “The ability to deliver a high-strength bond has many benefits for customers. It results in a faster process than metallising and brazing and does not require multiple high temperature processing steps. Morgan’s bonding technique is also highly cost-effective. In-house testing has shown that the technique produces bonds which are just as strong as braze or metallised assemblies. This innovative bonding technology is also suitable for assemblies with complex joints, providing a strong bond even on applications with complicated geometry.”