Realising the Smart City

RISC processors, rugged platforms and standardised software solutions are helping manufacturers meet the opportunity of a more connected world.

By Aaron Su, Director Embedded Core Group, Advantech.

The IoT comprises of billions of smart interconnected devices, each with their own ID, with cloud computing services processing all the information. Future smart cities will connect with all these devices and facilities to build up an all-around and intelligent system with integrated management of information that is reliably delivered via the cloud. Many system builders are now ramping up product roadmaps for the new era, but the smart city concept and IoT still have plenty of challenges to overcome before the idea is fully realised.

The related hardware and software infrastructure on the upper layer of intelligent computing (Macro Computing) has mostly been implemented. However, if all decisions surrounding thousands of devices on the bottom layer are made via the cloud computing layer, then a huge network burden would lead to congestion, delays or even crashes without warning, resulting in the failure of intelligent services to deliver. Therefore, decentralising the decision making process and letting the sensing layer balance the heavy loads are the best ways to truly realise the vision of connectivity for anything, at anytime and anywhere.

Simple tasks, simple architecture

Different from the Macro Computing upper layer, which executes multiple tasks on a single device and is prone to shutdowns which can damage the whole system, Micro Computing focuses on an individual simple task through one or several devices. This dispersion approach ensures a more stable operation even when some devices fail. In order to meet the requirements of the sensing layer such as small size, low power consumption, low cost and dedicated use, Reduced Instruction Set Computer (RISC) architectures have become the first choice for perception applications.

The last mile technologies of a smart city should be able to provide specialised and simplified solutions instead of trying to cover all possible functions regardless of whether they are needed or not, such as x86 based solutions try to do, consuming more power and more resources. Designing embedded applications with a RISC-based SoC platform can shift the focus onto required functionalities only; excluding a lot of unnecessary features early on in the development process. Advantages of this design also include lower power consumption, compact size and faster booting (less than one second), as well as reducing licensing costs by utilising free operating systems like Linux. In other words, products based on RISC architectures can provide smaller and better appointed systems, while implementation costs are relatively lower than those with x86 architectures.

In response to these trends, most chip makers have launched various RISC-based products for perception layer IoT applications of like Texas Instruments and Freescale processors. TI’s OMAP 5 processors are high-performance products with superior graphics capabilities and their low-power Sitara processors offer rich control features. Likewise, Freescale’s i.MX family (single-core, dual-core and quad-core) of processors provide high integration, low power consumption and multimedia support for vertical industries.

Despite there being so many excellent processors with suitable architectures for IoT, system integrators still encounter problems. Taking ARM as an example, the company does not manufacture but licenses its RISC processor architectures to other semiconductor manufacturers such as TI and Freescale that sell processors without motherboards. Therefore, system integrators still need to put a lot of time, manpower and resources into designing a new project for the vertical market which is characterised by small-volume but large-variety production. This practice means ARM-based projects often have low returns on investment which affects the popularity of RISC technology.

For each new project, System Integrators have not only to hire professionally qualified engineers who are proficient in ARM design, but they also have to choose components by themselves as well as conducting a variety of inspections and tests after the design stage. Inevitably, some design problems such as being unable to connect to peripherals through the I/O bus, or needing special drivers or software, or adding more network ports will increase development time. Also, communicating with original manufacturers to find appropriate solutions also significantly disrupts project schedules too.

For a long time, Advantech has played an intermediary role between chip suppliers and the system Integrator and aimed to benefit both of them and bridge the gap between supply-side and demand-side to accelerate the popularisation of RISC-related products and applications. Advantech has solved many customers' design problems in the past and offered customised solutions to improve performance such as providing ready usable software and hardware that has passed a series of tests, quickly getting responses from suppliers to change interfaces, or adding graphics acceleration software and extra Ethernet and CANBus ports to meet customers' special requirements. Though the demands of each vendor are different, they are accustomed to being self-sufficient, so Advantech helped to create a standardised service with software and hardware products so that developers can get the best solutions directly without doing everything themselves.

Rugged hardware for harsh environments

Generally, there are no standardised form factors for RISC architectures but recently a number of manufacturers introduced the Qseven and SMARC standards for handheld applications, and the RTX standard for rugged applications. These standards use a new concept to facilitate modular design by dividing embedded motherboards into two major parts: modules and carrier boards. Since the module gathers the core components (including CPU, memory, flash, power, etc.) with pre-defined dimensions and pin functions, developers can reuse the same ARM-based module and no longer need to spend a lot of effort developing the core platform and redesigning the entire board for each new project.

To meet diverse standards, Advantech offers a range of modules; the majority of ARM-based systems are used in harsh environments such as those with wide temperature differences and strong environmental interference, so defined the RTX 2.0 (RISC Technology eXtended) to optimise RISC-based platforms. By using 12 layer PCB designs of only 2.0mm thickness, it offers good circuit design with highly stable signals as well as durability against soldering cracks and deformation. Compared to golden finger connections, RTX’s four board-to-board connectors offer superior electrical performance with better resistance to oxidation and vibration. The connection method used will heavily affect the overall reliability of a system and the unsatisfactory design structure will further increase problems. Accordingly, RTX 2.0 is perfect for applications that require high stability and reliability such as robotic arms and limbs.

Additionally, since it is common to get 5, 12 or 24V power in factories, RTX 2.0 products provide wide voltage input ranges of (5-24V) as the basic specification so preventing high voltage damage to the motherboard and simplifying the system without adding conversion designs for insufficient voltage which results in the system being unable to boot. To eliminate electrical drift problems which are caused by temperature variations, Advantech specifically selected the components for its RTX module and each of them meets extended temperature ranges from -40 to +85˚C). Moreover, the thicker PCB with optimised trace width and trace space strengthens stability, while rigorous testing before shipment ensures the highest quality is achieved.

As for software, a complete programming environment not only requires an Embedded OS and Board Support Package (BSP) but also needs an Application Programming Interface (API) suite for developers to call and test the hardware resources. For example, when vendors want to employ different processors, the same function may be collocated with different calling address and thus increase potential risk for the customer’s application software. To facilitate application development, Advantech’s SUSI API firmware creates a method to always call the same address, making system integrators able to upgrade their systems with ease.

Elevator signage

More and more hotels and shopping malls are installing multi-media displays in their elevators, providing passengers with rich content during the waiting time in the elevators. Many such elevator displays come in small form factors and are built into the interface of the elevator controller. It’s a TV-like panel that shows floor information to notify the passengers of their position, and entertains them at the same time with interesting information.

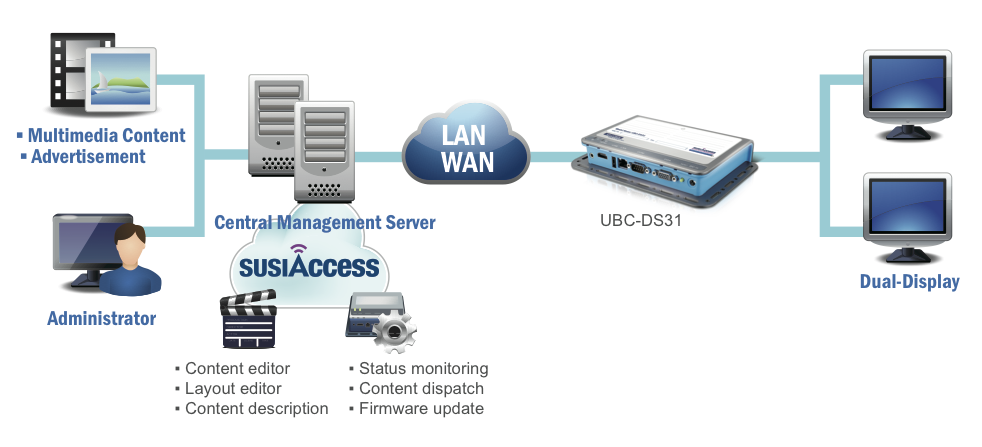

For small display devices broadcasting multimedia content, powerful graphic performance is a must. However, computers delivering better graphic performance usually require fans or heat sinks to deal with their thermal output. The customer previously used an x86 system in digital signage, which offered powerful performance but required a lot of space and also needed a heat sink and fans. But now, with the new solution Advantech provides, they use a RISC-based signage player with built-in graphic engine, and they have developed new products that support Full HD video output without the need for any fans or heat sink. Advantech UBC-DS31 runs on a Freescale ARM Cortex-A9 i.MX6 Dual 1GHz processor with 2D and 3D graphics built in, which supports dual displays with up to 1080p high resolution output on low power consumption. With this solution, the customer achieves the same video performance but reduces costs by using an economical RISC-based system instead of an x86 computer. UBC-DS31, with compact size and flexible mounting design, suits small-form-factor products that integrate easily into elevator systems. UBC-DS31 is also preloaded with SUSIAccess software for signage, which is based on Linux QT framework and integrates multiple functions including content editing/dispatch, layout editing, status monitoring, and firmware updates. Users can manage and control the content of all devices through the Ethernet or wirelessly from servers and management centres.

The benefit of a RISC-based solution is multifold due to its cost-effective performance, small form factor and avoidance of fans and heat sinks. Also system vendors’ design effort is reduced while the popularisation of RISC-based smart city solutions is being promoted.