CLPA pleased with SPS show after successful collaborations

The CC-Link Partner Association (CLPA) described the recent SPS Drives show as a great success this year, as the level of interest from visitors was a high testament to the increasing global acceptance of CC-Link IE and CC-Link. Double-digit growth year on year for the last decade has seen the installed base of CC-Link IE and CC-Link devices approach the 20 million mark, and the number of partner companies has now passed 3,000, making CLPA one of the largest open network associations worldwide.

Visitors to the fair noted the large catalogue of CC-Link IE and CC-Link products from CLPA partners, many of which were on show on the CLPA stand. With over 1,700 products available from more than 300 companies, users can enjoy maximum freedom of choice for the broadest spread of applications.

An important spur for the recent growth, and one of the topics visitors to the CLPA stand were most keen to discuss, was the cooperation between the CLPA and PROFINET & PROFIBUS International (PI). At SPS IPC Drives 2017, the CLPA was able to show the first product following the announcement of the completion of the interoperability specification at the 2016 fair. On the stand, CLPA displayed a working demonstration of a coupler device, developed by CLPA and PI partner Hilscher. The coupler enables users to achieve communication between CC-Link IE and PROFINET on different parts of a line, hugely increasing transparency and integration.

This simple bridge between CC-Link IE and PROFINET will dramatically reduce the engineering work that has traditionally been necessary to achieve integration across the heterogeneous network architectures that are a fact of life in numerous plants around the world. As an example, it will mean that a machine builder in Europe developing machines using PROFINET will be able to export those machines to Asia with the assurance of seamless integration into a CC-Link IE network architecture and vice versa.

This simple bridge between CC-Link IE and PROFINET will dramatically reduce the engineering work that has traditionally been necessary to achieve integration across the heterogeneous network architectures that are a fact of life in numerous plants around the world. As an example, it will mean that a machine builder in Europe developing machines using PROFINET will be able to export those machines to Asia with the assurance of seamless integration into a CC-Link IE network architecture and vice versa.

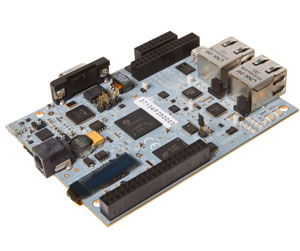

CLPA was also able to show the ever increasing range of development options for CC-Link IE and CC-Link. This included new support for CC-Link IE and CC-Link IE Field Basic (IEFB) from long time CLPA partner Hilscher on their netX platform. New CC-Link IEFB development options from Texas Instruments based on their Sitara line of processors were also on display. These combined with existing options from HMS, Mitsubishi Electric and Renesas to make visitors aware of the ever expanding range of industry standard product development solutions available from CLPA partners.

CLPA Europe General Manager John Browett commented: “While CC-Link IE has become an established technology leader, it is clear that while some device makers are undoubtedly interested in the benefits offered by CC-Link IE’s core technology, for various reasons they are not ready to support a gigabit physical layer. In some cases this is because of the communication platform that their products are currently based on, in others it will be because their products are targeted at a level in the market where gigabit performance is still a future requirement. CC-Link IEFB addresses all these kinds of issues by bringing accessibility to the network and its benefits without the need to support the gigabit physical layer. Furthermore, we are pleased to see some of our key partners such as Hilscher and TI offering a variety of solutions to device makers wanting to get on board with IEFB.”

CLPA also believed that visitors to the CLPA stand at SPS IPC Drives 2017 were also keen to learn about the CLPA’s new ‘CSP+ for Machine’ concept and the accompanying companion specification for OPC UA. The concept of CSP+ for Machine is to take a complete machine or system and define it as though it was a single device. This builds on CLPA’s existing CSP+ technology that applied the same concept to devices on a network in order to simplify configuration and maintenance. In the same way, CSP+ for Machine, combined with OPC UA, will make it easier than ever before to extract the necessary information from process equipment, thus delivering the necessary transparency required for Industry 4.0 applications.

“It’s a further example of how CC-Link IE is maintaining its technology leadership position,” asserts Browett. “Not only is it the sole technology that can genuinely offer the high bandwidth that is critical for Industry 4.0 applications, but now with this companion specification for OPC UA we can also ensure the greatest levels of connectivity, while simplifying the task of working with other plant systems.”