Sculpteo launches a unique 3D printed part recycling programme

Sculpteo offers to its customers RE-cycleo, a new recycling programme for parts printed with Nylon PA12 and Nylon PA11.

The recycled material will be used in the plastics industry and will give a second life to the old parts that can be recycled as many times as possible. With this original initiative, Sculpteo becomes one of the first 3D printing services to offer its clients recycling services, not only for clients' parts but also for production scrap.

Sculpteo, a commitment to more sustainable printing

As businesses move towards a better understanding of environmental issues, it has become urgent that industries like 3D printing pave the way for more sustainable solutions. Being concerned about the environmental impact of its activity, Sculpteo has worked to make the recycling of its clients' Nylon PA11 and Nylon PA12 obsolete parts possible. 3D printing presents certain advantages compared to other plastic manufacturing processes (local on-demand production, very low material loss, etc.). In this continuity, Sculpteo is expanding its line of sustainable materials like biosourced Nylon PA11. The company continues its research to make 3D printing even more sustainable and presents an interesting initiative through this new programme.

For Alexandre d’Orsetti, CEO of Sculpteo: “With RE-cycleo, we are inaugurating a new, more responsible way of producing, where we offer clients the possibility to upgrade their products. It has taken decades for mass industries to develop effective recycling programmes with their gigantic volumes. At Sculpteo, we can offer it from the first part.”

3D printed polymer recycling process

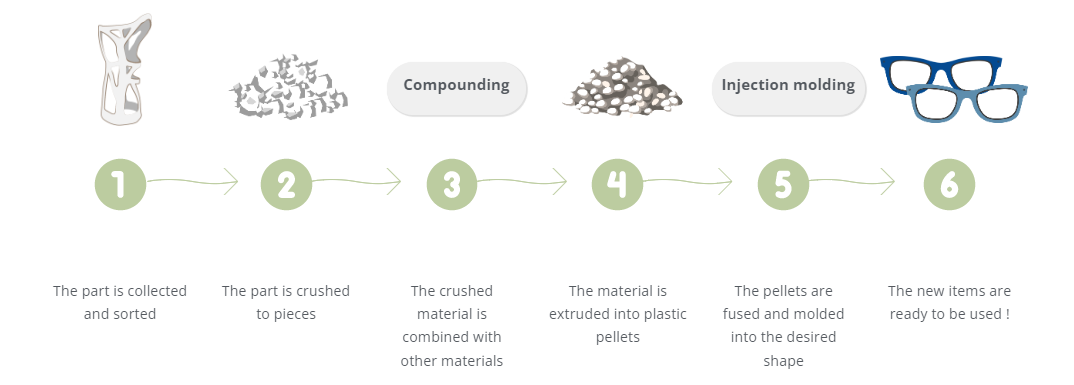

Non-binding image of a plastic part recycling process

Concerning the recycling process, the client will have to send, in the first place, their parts to Sculpteo with a destruction authorisation. Once received, the first step of this process will entail collecting and sorting the parts depending on the material (Nylon PA11 or Nylon PA12). The parts will then be placed in octabins that can contain hundreds of kilos of parts. The sorted nylon waste is then crushed into pieces. To keep the industrial secrecy and confidentiality of its clients, Sculpteo guarantees that the grinding only happens inside its factory. The crushed material is then sent to Arkema which will recycle it as part of their Virtucycle programme. The grinded material is analysed to ensure that there is no contamination. Then comes the compounding stage where the material will be remelted, chilled, cut into pellets that will be used in other industrial applications. These pellets form the final state of the new material which can now be used. In the case of injection moulding, the pellets will be melted and injected in a mould to create a new product like car components, tennis rackets, shoes, helmets, a suitcase, etc. This will give a remarkable second life to unused parts or end-of-life parts.

This whole process uses 100% renewable energy.