The importance of drying when cleaning medical PCBs

Medical electronics play an intrinsic part in modern healthcare. Electronics are at the heart of ground-breaking technology from life support systems and patient monitoring to devices like pacemakers and hearing aids. Quality, predictability and safety are all priority concerns to ensure patient safety. Therefore, cleaning medical PCBs found within these devices should not be underestimated. Emily Peck, Senior Chemist at MicroCare Corporation, explains.

Cleaning is critical to the success of all PCBs, whether they are used within consumer goods like smartwatches, or in critical medical devices like cochlear implants or defibrillators. Cleaning must be completed correctly with specific procedures followed to guarantee the lifespan of the electronic assembly.

Manufacturers have choices when it comes to PCB cleaning solutions, for example, at the benchtop or through vapour degreasing using innovative new cleaning fluids.

When it comes to benchtop cleaning, four important steps should always be followed: wet, scrub, rinse and dry. This sequence of steps is vital in making sure that electronic components are clean and perform correctly. The first three steps including: 1 - Wet the board with a pure cleaning fluid. 2 - Scrub it using a good quality scrubbing brush, then 3 - Rinse it off with more clean fluid are usually successfully followed. However, the final step of drying the PCB is often overlooked and in some instances, completely disregarded during the cleaning process.

For a circuit board to perform reliably it must not only be clean but also dry to ensure it functions correctly. Any moisture left on the surface of a PCB can lead to problems like dendrite growth, corrosion, electrochemical migration and delamination.

.jpg)

Above: Circuit Board Close-up – Densely packed and intricate circuit boards are a cleaning and drying challenge

Additionally, if the PCB is not dried correctly it can affect the adhesion of conformal coatings, an important process in medical electronic manufacturing, as the coating protects delicate electronics from contaminants like salts, sulfur and even earwax on a hearing aid for example. Moisture on the PCB can cause outgassing during the coating application when moisture on the board escapes. This can result in pin-holes and other conformal coating defects.

Moisture can be easily trapped on modern PCBs as they often have bottom termination components like land grid arrays and QFN (quad-flat no-leads) with very tight standoff heights. These structures make drying even more complicated and so it is important to ensure it is done correctly.

Drying with wipes

When benchtop cleaning, one of the most frequently used methods to dry a PCB is with a wipe. They may appear to be a simple tool, but there are fundamental considerations to take before using them on electronic assemblies to ensure maximum drying efficiency.

Make sure it is lint-free: Lint-free wipes work well in applications where re-contamination cannot be allowed, such as medical. A lint-free wipe will clean and dry any excess spray left behind from the cleaning fluid. It is also a good way to capture fluid under low-surface mounted components by gently pushing the wipe underneath.

Absorbency is a key feature when using a wipe for drying. It is important to check it will absorb the specific moisture being worked on as wipes perform differently according to their material construction. For example, some wipes will absorb cleaning fluids, but will not absorb water. It is essential to match the type of wipe absorbency to the contamination to be removed.

Material: Look at what the wipe is made from as this can affect just how clean and dry your PCB will be. Non-woven wipes are the best choice within the manufacture of medical electronics as they are made without glues or binders. This means they will not leave residue on the surface being cleaned resulting in a cleaner PCB. Another option is to choose pre-washed wipes or those with heat or laser-sealed edges. These will help to reduce lint and contamination when drying the PCB.

Packaging: When choosing a drying wipe, its packaging is extremely important. If static dissipative properties are important, choose wipes sealed in electrostatic discharge (ESD) safe wrappers. ESD wipes will limit dust attraction and also reduce static damage to the electronic components. These unique wipes are typically cut and packaged in a specialist facility to ensure their purity.

Dry using the duster method

If post reflow, rework assembly is undertaken at the benchtop then a dust remover is an effective drying method. This will quickly and easily blow out trapped moisture from underneath larger components that a wipe alone may not reach. A dust remover can be used to specifically target moisture in hard-to-reach areas of the PCB. Use a duster and a wipe when drying to help stop the spread of contamination by preventing the fluid from being pushed back onto the board.

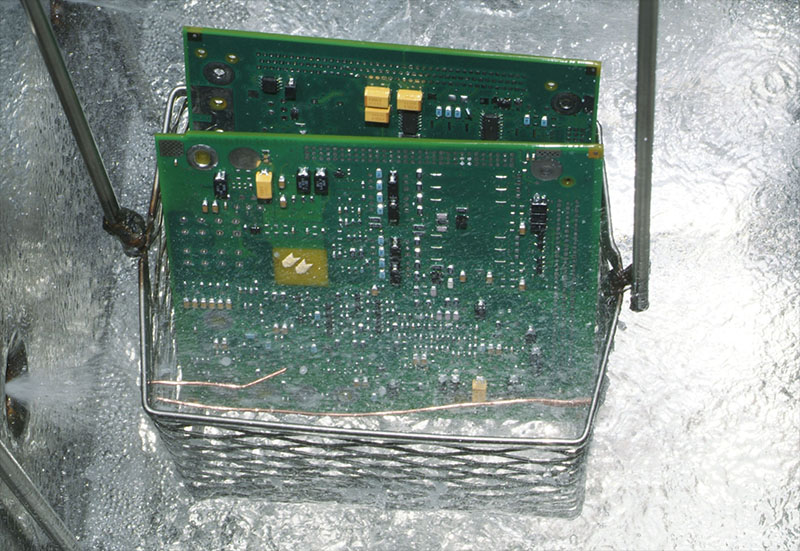

Above: Circuit board in vapour degreaser - PCBs come out of the vapour degreaser clean, dry, spot-free and cool

When selecting a duster for drying applications look at the safety credentials. Canned air may be inexpensive and readily available, but many of these formulations are highly-flammable. As a safer alternative choose a dust remover that is formulated with non-flammable gas.

You may also want to consider using a dust remover that works effectively at all angles. A 360° dust remover can blow out moisture easily and will allow operators the flexibility to quickly dry very complex or intricate PCBs.

Batch drying of PCBs

When a larger number of PCBs have to be dried simultaneously, a bulk or batch drying method is required. Convection ovens with air knives can be used, but they are not an effective way to dry low-mounted components found in medical electronics.

It is important to consider the temperature and airflow when using drying ovens. If the circulating airflow isn’t strong enough or if the temperature isn’t high enough, moisture may still be present on the PCB. Or if the temperature is too high, it can damage the surface of the board, or the components on it by hardening any residual contaminants left behind.

Vapour cleaning and drying

Vapour degreasing is the most viable option for batch cleaning and drying PCBs since it eliminates the concerns of convection ovens. It is also the most effective critical cleaning process which successfully satisfies the cleaning performance requirements needed within the medical device industry and the regulatory regimes in different countries.

The process uses cleaning fluid immersion, combined with vapour rinsing and vapour drying, to remove all types of contaminants including fluxes, pastes, particulates and residue.

A vapour degreasing system consists of two chambers filled with a non-flammable cleaning fluid. The boil sump heats the fluid to a low-temperature boil, usually between +40˚C/105˚F and +65°C/165°F, to produce a pure, clear and dense vapour blanket. PCBs are lowered into the boiling cleaning fluid which heats, loosens and removes most of the contamination.

.jpg)

Above: Circuit board with wipe - It is essential to match the type of wipe absorbency to the contamination to be removed

The next stage is the rinse sump where any remaining contaminant is rinsed away. The PCBs are finally held inside the vapour blanket which dries and cools them.

Vapour degreasing delivers very high levels of cleanliness to ensure patient safety and product performance. The process uses specially engineered cleaning fluid with a low surface tension. This means it can penetrate and clean the entire board, including under tightly-spaced components to remove the contaminant. Because this method uses a low temperature fluid, the risk of damaging the PCBs is reduced and the purity of the cleaning fluid means it leaves no residue behind, therefore ensuring a perfectly clean board.

Importantly, vapour degreasing helps to eliminate bio-burden risk, essential when manufacturing medical devices. Bioburden is when bacteria remains on a surface that has not been sterilised. Even the smallest amount of moisture in hard-to-reach areas can encourage the growth of bacteria. If it is not cleaned sufficiently it can result in increased complications during the validation of the product and issues with the reliability of the device. Cleaning fluids in a vapour degreaser are hostile to pyrogens and will minimise the bioburden risk. Because PCBs come out of the vapour degreaser clean, dry, spot-free and cool enough for immediate coating or packaging, the possibility of bioburden contamination is reduced considerably as any moisture is removed.

Remove moisture at all stages

Moisture is a potential threat to a PCB in the cleaning and drying phase, and it is also an enemy after the manufacturing process when in storage. PCBs can draw moisture from the air so it is important to keep them dry and ideally within a climate-controlled area. Correctly managing PCBs during pre-and-post cleaning, and during storage and shipping, will help to protect moisture sensitive components on the board.

Device performance has to be the most fundamental concern for manufacturers particularly for those within the medical sector. To guarantee the reliability and functionality of a device and the PCBs within it, it is critical to remove any moisture. Whether using a benchtop method or a vapour degreaser, it is important to ensure the PCBs are not only clean but also dry for optimum dependability and performance.