ESD safe materials to accelerate 3D printing in electronics manufacturing

Material choice is one of the key considerations for an engineer when it comes to choosing a manufacturing method; and they can benefit greatly from having access to ESD safe materials (electrostatic discharge) which are critical for 3D printing electrostatic sensitive fixtures, enclosures, and parts. Brandon Sweeney, Head of R&D for Materials and Co-founder of Essentium, explains further.

As adoption of additive manufacturing continues to gain pace, enabling new production possibilities across industrial markets, there is a need for high performance materials such as high temperature nylon (HTN). It is materials such as this that will satisfy demand for industrial scale 3D printing for the most demanding applications such as electrical connectors, medical instruments, and chip test sockets.

However, ESD safe materials are not all created equal and some materials may not be as ESD safe as once thought. In the past, a key issue with ESD materials was that they require a high loading level of conductive additives to qualify as ESD safe – and those high levels degrade the material properties making them unsafe for electrostatic-sensitive products. Let’s take a deeper look at ESD safe materials and their increasing role in 3D Printing for electronics manufacturing.

ESD safe materials for 3D printing

The best way to understand ESD safe 3D printing materials is to understand where ESD safe plastics have been used in industry historically. There are three primary uses for ESD safe plastics: electronics manufacturing, for example ESD safe jigs and fixtures for printed circuit board manufacturing; materials in a combustible/explosive environment such as all the plastic parts near a gas pump; and nuisance static charge elimination, for example powder conveying materials.

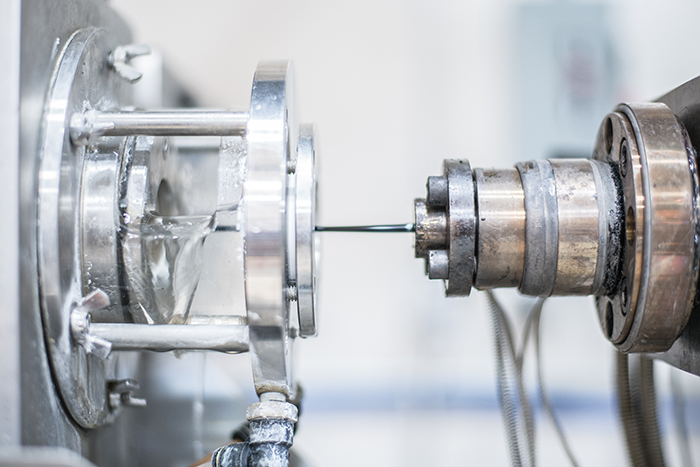

We see the biggest demand in the electronics manufacturing industry where millions of new electronic devices are being developed and manufactured each day. Every one of these devices requires a multitude of custom jigs, fixtures, pallets, nests and assembly aids to produce. Traditionally these components are made in medium to low volumes with traditional subtractive manufacturing techniques, namely CNC milling. This results in long lead times and very expensive tooling charges that get passed on to the customer as non-reoccurring engineering expenses (NRE).

Additive manufacturing is changing all of this by allowing manufacturers to design jigs and fixtures to be 3D printed with advanced engineering grade materials that meet ESD surface resistance requirements. Lead times can be reduced from weeks to hours, multi-component assemblies can be reduced into a single 3D printed part, and the cost savings in materials and man-hours typically exceeds 90%. The key to all of this is proper materials that can survive the demanding processing steps associated with electronics manufacturing.

Challenges of traditional ESD safe materials

To make an insulating polymer electrically conductive in the range specified for ESD safe materials, you typically add a conductive filler like carbon black, or graphite to the polymer forming a composite. Traditional ESD safe materials are designed with injection moulding or machining in mind. Most of the 3D printable ESD safe materials on the market were simply borrowed from injection moulding formulations. The problem with that is you end up with materials that are not optimised for an additive manufacturing process.

Materials modified for ESD traditionally have a large component of added graphite or carbon black, often between 15% and 25%, this really changes the material and results in several problems and compromises. Many materials with a large amount of added carbon are more fragile, often breaking on impact. These materials also suffer from a severe marring issue, with material transferring from the rack, jig, or fixture to the part being stored or supported. This can also result in air-born contamination that could find its way into a solder joint or another location that could compromise the performance and reliability of the product. Latent, undetected contamination is particularly dangerous when products are shipped, appearing to function well and failing later in the field. The result could be a costly recall.

Carbon nanotubes to create ESD safe materials

Carbon nanotubes are a cutting-edge class of nanomaterials that solve many of the challenges associated with other conductive fillers. Carbon nanotubes can create an electrically conductive network in a polymer matrix at very low loading levels because of its incredibly high aspect ratio (ratio of length to diameter).

Carbon nanotubes are also incredible conductors of electricity, which allows a very wide range of nanotube-polymer conductivity values from electrically conductive (think 3D printed circuits and electromagnetic interference (EMI) shielding properties) to ESD safe static dissipative values, all the way down to electrically insulating (no nanotube loading). We can select the precise material properties we want by tuning the loading level of nanotubes in the polymer. Carbon nanotubes also tend to reinforce the polymer matrix making it slightly stronger and more wear resistant. The nanotubes are completely bound to the polymer matrix meaning they cannot rub off onto sensitive devices or cosmetic surfaces.

It’s crucial to create a strong bond between thermoplastics and carbon fillers to eliminate the possibility of sloughing conductive particles onto electronic assemblies during manufacturing. Essentium use high quality, high purity carbon nanotubes and a proprietary extrusion process to extrude a multilayer 3D printer filament that concentrates the nanotubes onto the surface of the filament rather than throughout the entire volume of the material. This creates a high quality ESD safe material where the nanotubes are used intelligently and sparingly, resulting in a higher performance material without excess conductive particles with the potential to slough off.

Solving unmet needs

Essentium developed materials to address two major pain points: ESD safe 3D printing materials that are non-marring and do not compromise its engineering properties. We’ve discussed the first point already. The counterpart to being chalky is brittleness. Most ESD safe materials have so much conductive filler added to the polymer that it begins to alter the mechanical properties of the base polymer resulting in lower toughness, impact resistance, and elongation at break. To counteract this, manufacturers will generally add plasticisers to restore some of the ductility to the composite. This in turn leads to more compromises in the mechanical properties of the material, reducing its overall performance.

Essentium ‘Z’ ESD safe filaments eliminate these compromises. Because the bulk majority of the filament in the core is the base polymer, you are able to retain all of the mechanical and thermal properties of the material. The conductive outer layer of the filament is in the order of a few microns after printing (fractions of the width of a human hair) and does not appreciably alter the physical properties, it simply adds an ESD safe layer embedded throughout the entire printed part. One final benefit of this process is cost.

High performance conductive fillers are typically expensive and can affect the base price of the polymer resin significantly. With Essentium’s process, only a small fraction of the filament mass is composed of the nanotube compound, so the company produce its materials without a high cap on the cost of goods sold (COGS). This means that as it continues to scale its materials in the industrial marketplace, it will be able to offer competitive pricing for its high performance, no-compromise materials.

Advancing ESD safe materials

In the electronics manufacturing industry there’s a growing need for high temperature processes, so when you’re assembling a circuit board and doing a reflow process on it, you want to make sure that if it’s going through a reflow oven and you have a tray carrying a bunch of boards that you can contain all the pieces and survive the temperatures without melting and destroying the part.

To address this demand, Essentium recently introduced a high temperature nylon base resin, the Essentium HTN-Z – which is an ESD grade, containing electrically conductive elements inside of a polymer shell enabled by a multi-layered architecture. With ESD safety, HTN-Z can be harnessed by electronics manufacturers to produce fixture components for printed circuit board assembly (PCBA). While the process of inserting electronic components into printed circuit boards is typically carried out by humans who are pretty good at being able to grab a screw, locate it and insert it into a hole, a move to robots is seemingly inevitable for such tasks. That means more fixtures will be required which increases the demand for ESD safe materials.

While additive manufacturing is poised to play an integral part in manufacturers’ production lines, widespread adoption has been hampered by limited access to a broad set of materials that meet requirements for reliability, repeatability and performance of 3D printed parts in industrial environments. Essentium believe an open ecosystem will play an important role in removing this barrier. This is why Essentium works with partners like LEHVOSS Group and BASF in an open additive ecosystem to give customers more control, greater choice in materials and ultimately lower cost and higher volumes. As a result, customers can reap the benefits of dramatically reduced lead times, previously multi-component assemblies becoming single 3D printed parts, and realising immense business advantage through savings in materials and man-hours.