The ART of keeping utilities reliable and efficient

New line current sensors allow utilities to monitor their overhead distribution lines to maximise their capacity and prevent clearance violations, explains Patrick Schuler, LEM

The high voltage transmission grid is already highly automated and monitored through SCADA (supervisory control and data acquisition) control and energy management systems. In contrast, the medium-low voltage distribution grid has very limited monitoring and control. Why? More often than not, utilities fail to monitor their many medium voltage sub-stations, this is due to the expense of retrofitting and moderninsing them, and because of the time it takes to plan and build. The implementation of traditional sub-station monitoring requires complicated engineering; this includes the use of remote terminal units with new conduits, wiring to relays and current transformers. Engineers must schedule outages to disconnect the feeders, which takes time and may only be possible during low power consumption needs. Once the hardware has been installed, the utility has to program and integrate all the hardware into a complex SCADA system, which is a significant and difficult challenge for many utilities. There must be a better way.

Below the feeder level, remote monitoring is absent with the exception of customer billing meter points, where smart meters are becoming prevalent to read, monitor and control. However, these smart meters are only collecting and communicating voltage, current, power, reactive power and energy data rather than power quality data sets like cos phi, total harmonic distortion, flicker, voltage dips, transients, waveforms and time series. The smart meter does not collect a lot of data outside its billing-focused function. Sub-stations and distribution power lines are two of the most valuable assets for utilities that require crucial power flow data to provide the most reliable service.

High value data

The most relevant data in the distribution grid is about the location and cause of faults and non-fault events, high-impedance faults, consumption peaks, handling distributed renewable energy and electric vehicle (EV) charging, feeder outages, and many others – all high-value data that is not addressed by today’s systems.

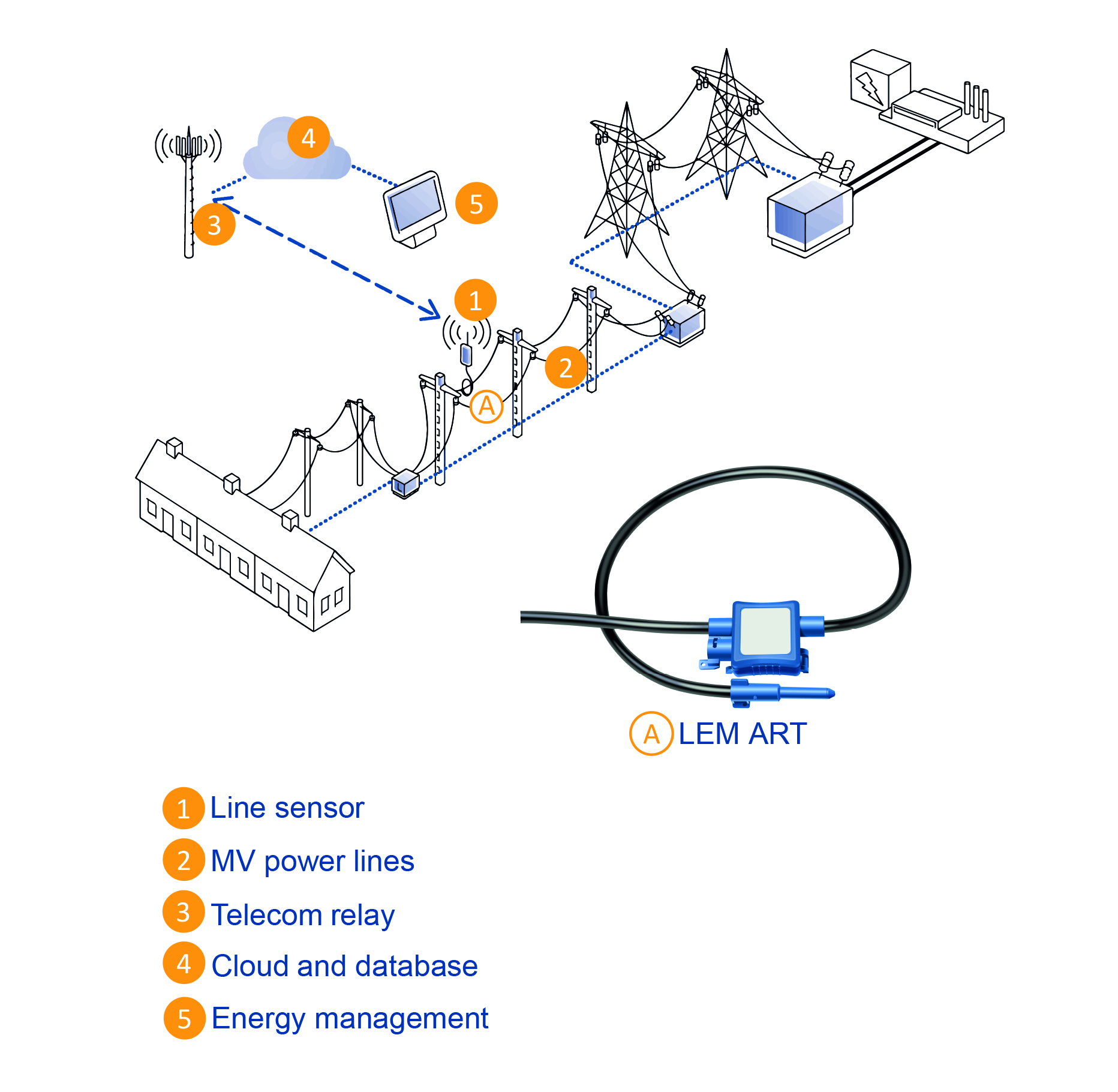

Figure 1: A line sensor makes monitoring overhead power lines faster, easier and cheaper with IoT networks

Figure 1: A line sensor makes monitoring overhead power lines faster, easier and cheaper with IoT networks

Now monitoring overhead power lines has been made possible faster, easier and cheaper with new internet of things (IoT) telecomms networks like NB-IoT and LPWAN (Figure 1). Thanks to a line sensor (1), installed between two medium voltage (MV) poles (2), the grid operator can visualise, in real-time, the current flow in order to optimise the power line capacity to distribute more electricity. The wireless line sensor (1) sends data over a telecomms relay (3) to a secured database in the cloud (4) or on the premise. The energy management platform (5) can regulate, alert and notify the maintenance team if needed. New line sensors are now using the LEM Rogowski coil ART (A) to measure the current, detect line aging depending on the level of current, and prioritise line capacity.

Previously, without visibility about the grid, the generated renewable energy distributed through an overhead line could be overloaded (shown in red, Figure 2). Thanks to the three-phase line sensor system, the extra power in one of the lines can be re-distributed to the adjacent lines (shown in black) therefore reducing the initial line (shown in blue) capacity to an acceptable level. Overall, the capacity output of the power grid is then maximised.

Figure 2: Before and after line sensor installation

The line sensor additionally provides periodic time-synchronised measurements to facilitate improved situational awareness and operations, such as current, both amplitude and phase, conductor surface temperature and detects fault conditions, enabling rapid identification and notification. This three phase line sensor system in the power distribution are equalised in real-time among the different lines within a meshed network

The AC measurement can now be achieved with the LEM ART split-core Rogowski coil.

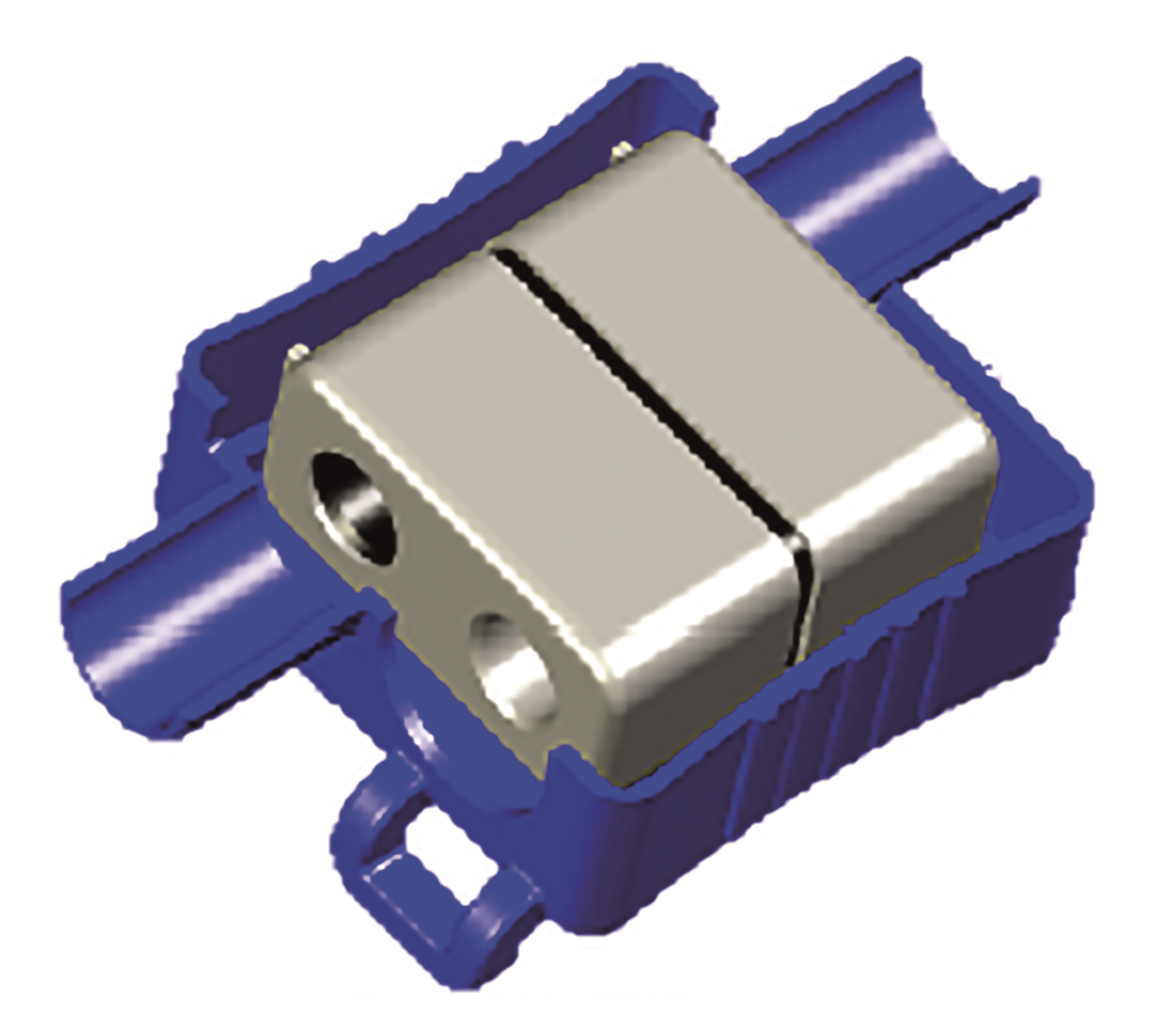

Figure 3: Ferrite core of an ART Rogowski coil

Figure 3: Ferrite core of an ART Rogowski coil

ART has a practical, one-size-fits-all current loop, excellent ferrite core, great accuracy, light, safe mV output and water resistant coil.

The art of ART

Recent developments have revolutionised the characteristics of ferrite at 50/60Hz, bringing many advantages. This new type of ferrite has significantly improved permeability and has been implemented in the ART Rogowski coil. ART takes advantage of the intrinsic ferrite qualities of high accuracy and excellent linearity, even at very low current levels, no phase-shift between input and output currents, no air gaps and being virtually insensitive to ageing and temperature changes, low position dependent error close to the clasp of the coil and low cost, compared with potentiometer based Rogowski coils.

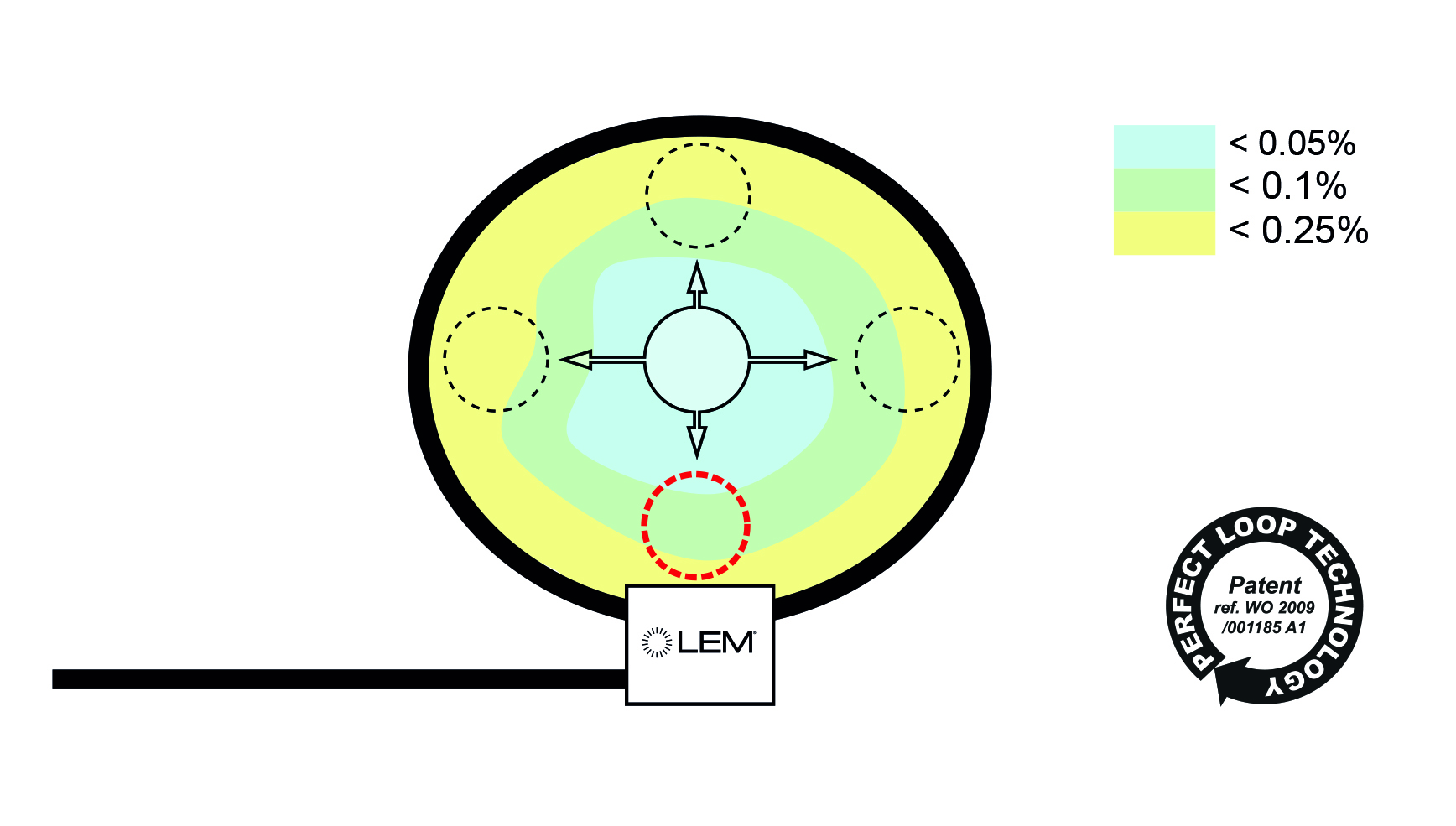

The overall sensitivity to the position of the primary conductor can be controlled. Close to the clasp errors are often unavoidable, except for the patented ferrite-based ART Rogowski coil, reports LEM (see Figure 4).

Figure 4: Position sensitivity of an ART Rogowski coil

The ART Rogowski coil class 0.5 has made huge progress, allowing small, light, sensitive and flexible current sensing for MV grids. The major improvements that have been made in the design and manufacturing processes have enabled a reduction in both the cost and the sensitivity to the coil positioning around the primary cable.

People consume more electricity than ever before and have an expectation that they will access their electricity without fault or interruption. The line sensor provides situational awareness along distribution feeders allowing utilities to operate and respond based on prevailing conditions. The system directs pre-emptive patrol and maintenance crews to the affected grid locations, enabling utilities to avoid potential short or long electricity interruptions. It reduces outage frequency, resulting in the reduction of the momentary average interruption frequency index (MAIFI) and system average interruption frequency index (SAIFI). Both indexes serve as valuable tools for evaluating a utility’s performance and reliability. Some countries have already put in place regulations that require a utility to reimburse customers for long electricity interruptions.

When installed with the hot stick or insulated gloves on the overhead power line, LEM’s ART Rogowski is a safe, easy-to-install, light but robust current measurement alternative to heavy and expensive current transformers, therefore improving the overall performance, reliability and efficiency of the line sensor.