The 48V electrical system: the first step towards electromobility

In order to keep pace with ever-stricter limits for CO2 emissions, the shift to the 48V electrical system is unavoidable. What does this 'transformation' of conventional power applications in the vehicle to higher voltage levels mean for electronic components?

Author: Andreas Mangler, Director Strategic Marketing & Communications – Member of the Extended Executive Board, Rutronik

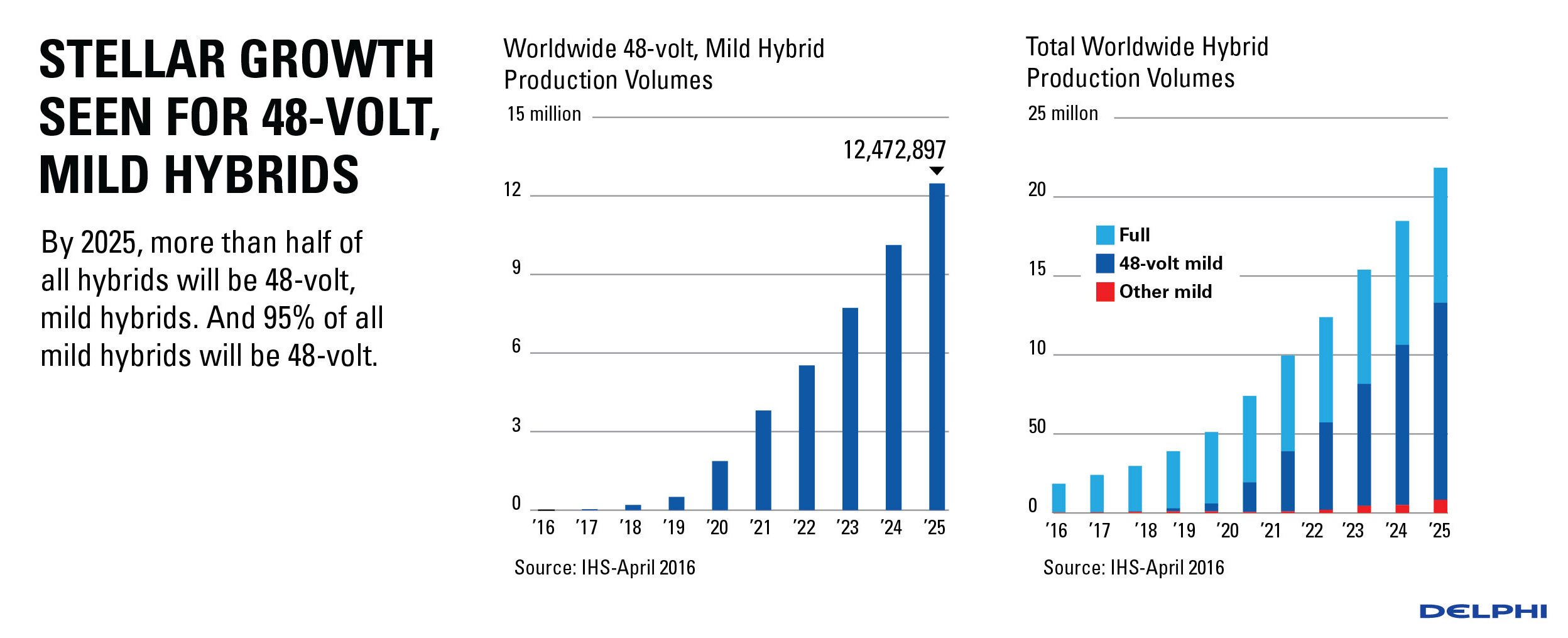

The emissions scandal has made this clear: The current CO2 limits are practically unattainable with internal combustion engines. Many countries will be further tightening their requirements in the coming years: Europe will reduce the current limit of 130g/km to 95g/km in 2020, while the US is set to follow suit in 2025 with a limit of 102g/km. As an interim step towards electromobility, powerful hybrid drives in various topologies and configurations offer defined solutions. In this regard, mild hybrid variants incorporating starter/engine/generator functions represent an important step towards the electrification of the powertrain.

One of the basic prerequisites for this is the 48V electrical system. This is because the 12V electrical system on its own would require very high currents. In addition, it can no longer meet the ever-increasing demands of more and more consumers in an acceptable manner.

In order to continue using the components with low power consumption fitted, many suppliers are retaining the 12V electrical system for the time being. According to the VDA (German Association of the Automotive Industry), around four million vehicles will be fitted with 48V subsidiary electrical systems in 2020. By 2026, this figure will rise to some ten million vehicles, or roughly one in every ten vehicles worldwide.

This requires a complete change in the architecture of the vehicle. Since the voltage is four times higher, the currents must and/or can be reduced in order to keep the power unchanged.

The primary requirement is to ensure optimum integration of the electric motor in the vehicle topology so that it can also switch to generator mode. This enables recuperation of braking energy, that is, the process of recovering energy lost during braking and feeding it back to the battery. This is referred to as emission-free sailing/coasting. In this scenario, the vehicle's speed in free-run operation is maintained using recuperated energy from the battery. Entering and exiting a parking space under pure electric power as well as a CO2 neutral e-boost are also possible. Furthermore, the 48V subsidiary electrical system creates a basis for further innovations without forcing suppliers to rely on larger engines.

The mild hybrid

The 48V subsidiary electrical system in these types of mild hybrid models should be seen as first steps into hybrid technology and therefore as first steps in the direction of the 'genuine' electrification of entire vehicle series as full hybrids.

In contrast to full-hybrid models that operate at significantly higher voltages of up to 360V, mild hybrids are configured without a charging function. Since both powertrains are not fully decoupled, they do not permit pure electric driving, but merely coasting, an automatic start-stop system and smooth starting up. However, coasting alone reduces CO2 emissions by up to twelve percent depending on the measurement guideline and driving style.

The decision for a 48V subsidiary electrical system results in fixed specifications for the OEM, the suppliers and the electronics.

Recuperation

During recuperation, energy of between 3-12kW is recovered – which for 12kW would amount to no less than 1,000A at 12V! In the 48V electrical system, this is reduced to a quarter, or max. 250A. However, the higher voltage requires an added focus on safety requirements. To comply with the low voltage directive, voltage peaks in excess of 60V must be avoided. To ensure that the circuit functions safely, it is necessary to define the optimum working range and to implement safety measures to provide protection against overvoltage and undervoltage.

The recuperation power depends on the size of the engine among other things: Drag losses increase in line with the number of cylinders and the recuperation power falls. For this reason, a fixed coupling between the mechanical motor and the starter generator is recommended for smaller engines. For larger engines, a separated, active decoupled connection makes more sense as it allows braking energy to be fed back into the battery.

Weight reduction

Thanks to the lower currents in the 48V electrical system, cables with significantly lower cross-sections can be used. As a result, the vehicle weight is reduced by up to 10kg, which also helps lower CO2 emissions. What's more, mechanical components such as the steering system can be replaced with – smaller and lighter – electric units.

Lower consumption – greater comfort

With regard to integration into the 48V subsidiary electrical system, the most suitable items to begin with are assemblies with high power consumption, such as PTC auxiliary heaters, seat or front windshield heating systems as well as the climate control system. Over the medium term, they will be joined by other components such as electric steering, chassis stabilisation, audio power amplifiers, and LED lighting, which can then be operated at higher voltages. In the long term, they will be followed by the smaller consumers.

This will involve combining utility with comfort as these changes also frequently result in enhanced driving comfort. For instance, if the front and rear windshield heating is operated at a higher power of 1.5kW at 48V, the fan only needs to rotate at a lower speed. The PTC auxiliary heater in the 48V electrical system is also available with full power at idle speed and immediately after the engine is started. This allows it to heat up the interior compartment, engine, and transmission before the engine warms up. This is all the more important in hybrid vehicles as the electric motor generates virtually no waste heat.

In the context of the engine's automatic start/stop system, the 48V electrical system also allows swift, smooth starting without the internal combustion engine, for instance, in stop/start traffic. If the compressor for the climate control system is connected to the 48V electrical system, the PTC heater, ventilation and fans as well as a contact heater can continue to operate for up to approximately three minutes, even during an automatic engine stop.

Components in the 48V electrical system

The key components of the 48V electrical system are the start/stop generator, the battery – currently based on lithium ion technology – as well as the electric steering and heaters. This requires a new design for all corresponding control units to ensure that they meet the changed requirements that apply at higher voltages.

The starter generator and the power electronics can be implemented with a claw pole machine or a synchronous machine. The claw pole variant is more closely aligned with the 12V standard, enables cost-effective mass production and is easier to integrate into new vehicles. However, the V-belt has a negative influence on the torque transmission, and the lifetime of the slip-ring system is limited. In the synchronous machine, the permanent magnet ensures maximum power density. Since it does not use a slip ring, it is practically maintenance-free. The disadvantages are the higher costs, more complex integration, and the machine's use of rare earth elements.

The battery system includes the battery cells themselves, a cooling system, the specific housing and stack structure, the cell balancing and a sophisticated battery management system. The latter uses various diagnostic functions such as temperature monitoring, overvoltage and undervoltage monitoring to ensure that the battery cells remain within their safe working range. In this regard, a whole range of design goals must be taken into account, above all rapid charging at 12kW, high energy density, compliance with crash requirements as well as a long lifetime coupled with minimum cost. Lithium ion batteries meet most of these requirements. Cylindrical cells also offer the advantage of coming in cost-effective standard sizes that can be connected in parallel and in series as a stack. Determining the State-of-Health (S-o-H) of the battery cells poses and additional challenge. Current battery management systems adhere to strict documenting procedures to record the charging and discharging operations. In the process, they accumulate vast quantities of data due to the complicated Coulomb counting procedures, ultimately in order to draw conclusions regarding the state of the battery. The measurement of complex impedances under real-world conditions as a means of making statements about the S-o-H of the battery is currently neither cost-effective nor ready for series production. It is precisely in this area of battery management systems that Rutronik is actively driving research and development together with leading universities.

A core component of the 48V subsidiary electrical system is also the bidirectional DC/DC converter that connects both systems. This unit typically offers an output of 3kW with peaks of up to 3.5kW for 2s and is passively cooled to achieve efficiency of at least 96%.

Various suppliers are already offering solutions that meet the new requirements of the 48V electrical system. For instance, tier-1 supplier Valeo has developed solutions to support the powertrains. Others such as Continental, Bosch, Preh or Delphi are preparing solutions of their own.

However, as neither mild nor full hybrid vehicles are to be seen in large numbers on the roads, the segment is relatively uninteresting in financial terms for the distribution sector – for the time being. For when it comes to meeting the CO2 regulations, there is no alternative. A further boost is provided by the policymakers with their electromobility support program. With help of funding for electric vehicles, which also includes hybrid models, tax incentives and the roll-out of charging points, the objective is to bring half a million electric vehicles onto German roads by 2020.

To achieve this goal, the Automotive Business Unit at Rutronik is offering its automotive customers a range of carefully chosen components from select suppliers as well as specific technical and commercial support at global level. In close cooperation and coordination with selected suppliers and their specific latest-generation automotive components, the Automotive Business Unit supports defined focus customers in meeting the current challenges across the wide range of automotive applications, specifically in the area of e-mobility. Other areas of focus of these activities and applications include car-to-car communication, infotainment, driver assistance systems and lighting, as well as the continuously rising safety requirements according to ISO 26262, which also cover on-board electrical applications.

Worldwide customer support

With its international and cross-location orientation, the Automotive Business Unit offers customers support across the world. For on-site support, it works together with the local Rutronik field application engineers and business development managers.