Power supply architectures for isolated gate drivers

Many power electronic applications such as automotive traction drives, PV inverter, railway traction drives and servo drives require a three-phase inverter power stage to convert DC to three phase AC voltage. Gate drivers are needed to drive the semiconductor devices. Vikneswaran Thayumanasamy and Kevin Lenz look at topology options

In most cases due to the safety requirements, isolated gate drivers that provide isolation between the low voltage side and high voltage side are required. Isolated gate drivers typically need a power supply of 5.0V to drive the logic circuit and an isolated supply voltage (8.0 to around 25V) to drive the power semiconductor device. One of the most common topologies to generate the isolated power supply for the gate driver is the flyback converter and there are several types of isolated power supply architectures for gate drivers.

In a three-phase inverter system, the isolated power supply architectures for the gate drivers are categorised as distributed power supply architecture and centralised power supply architecture.

Centralised power supply architecture:

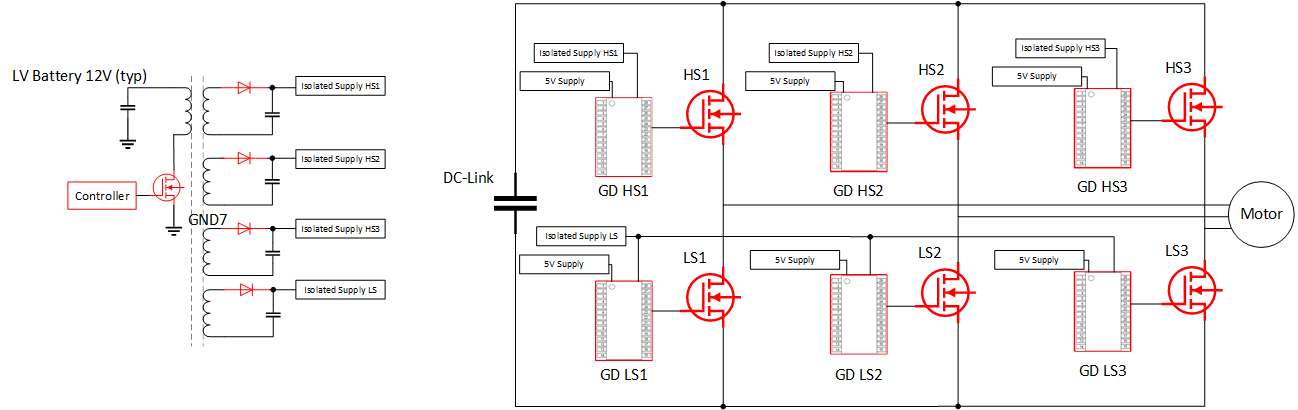

Figure 1 shows the realisation of centralised power supply architecture in a three-phase motor drive. The three high side switches are labelled HS1, HS2, HS3 and the three low side switches are LS1, LS2, LS3. The gate drivers for high side and low side switches are GD HS and GD LS respectively. Typically a 5.0V supply is needed to drive the logic block of the isolated gate drivers and isolated power supplies are required for the output side of the driver. The isolated power supplies needed for the output stage are generated from a single transformer with multiple secondary windings. The topology shown in Figure 1 is a flyback converter. The transformer consists of a single primary winding and is supplied from the low voltage battery (typically 12V) in a hybrid electric vehicle (HEV) or a plug-in HEV (PHEV). Three of the secondary windings supply the three high side switches (isolated supply HS1, HS2 and HS3). A single winding is sufficient to supply the three low side switches (isolated supply, LS). Such a power supply architecture that requires a single transformer with multiple secondary side windings, a single MOSFET switch and a controller IC is a centralised power supply.

Figure 1: Centralised isolated power supply architecture for gate driver. (The components marked in red are available in Rohm‘s product portfolio)

Distributed power supply architecture

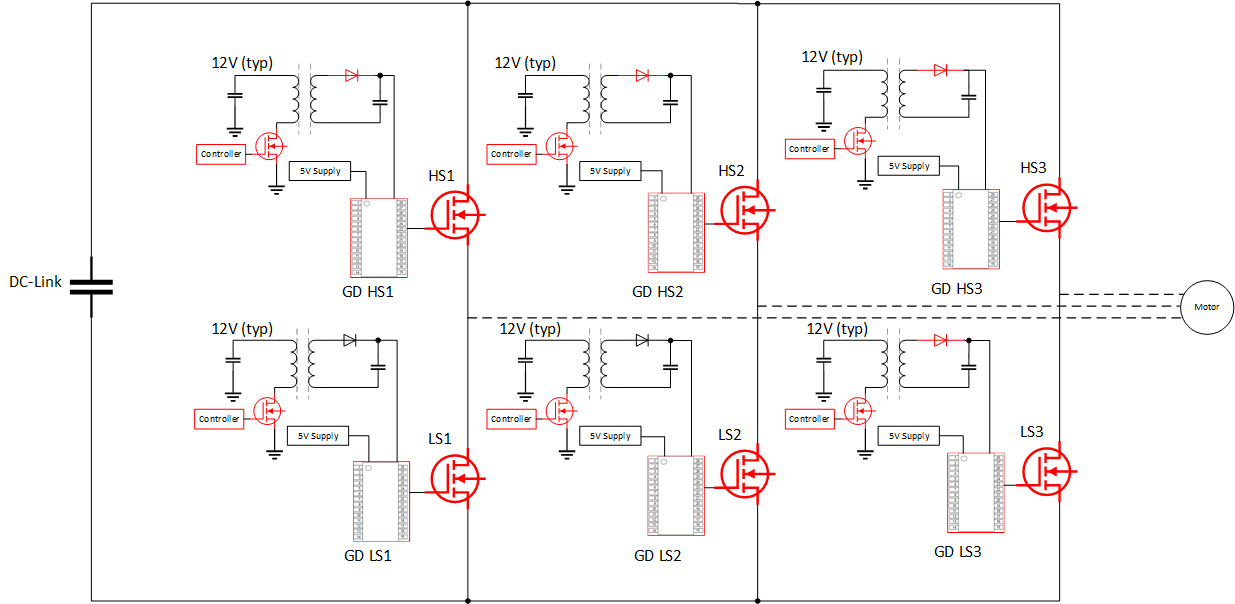

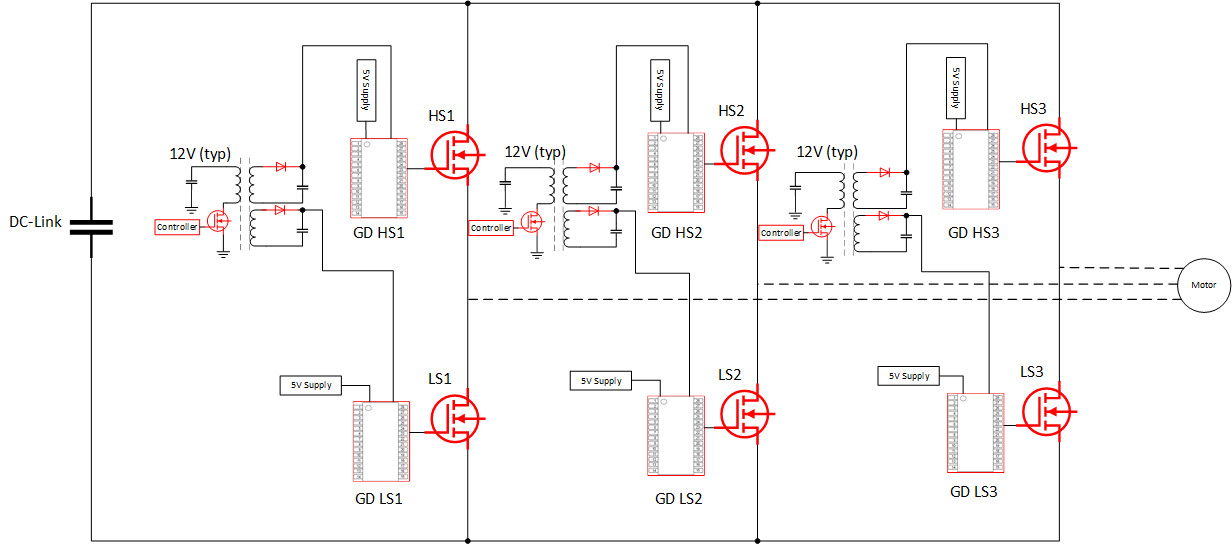

Figure 2 and Figure 3 show the two different types of realisation of distributed power supply architecture for isolated gate drivers in a three-phase motor drive. Figure 2 shows a distributed power supply architecture with six separate flyback converters which are used to generate the isolated power supply required for the six switches. Figure 3 shows a distributed power supply architecture which uses another method to realise a distributed power supply. Here, a single transfomer with two separate windings is used to generate the isolated power supply for the two gate drivers in a phase leg. For the complete three-phase inverter system in case of the first example (Figure 2), six transformers, MOSFETs, controller ICs are required. In the second example (Figure 3), the distributed supply architecture, requires three transformers (with two secondary windings), MOSFETs and controller ICs.

Figure 2: Distributed power architecture with six separate flyback converters. (The components marked in red are available in Rohm‘s product portfolio)

Distributed vs centralised power supplies

In the case of the centralised power supply architecture in Figure 1, a single transformer is required to house the four separate windings to supply the high side and low side switches. The same transformer will supply the average gate current for all the six switches in a three-phase inverter. In the case of a distributed power supply architecture, one transformer is allocated for supplying one isolated gate driver and in the end average gate current for only one switch needs to be considered. Hence the power rating of the transformer in case of centralised power supply architecture tends to be higher than that of distributed power supply architecture. The higher power requirement and the ability to house four separate windings at the secondary side, means that the flyback transformer in a centralised architecture tends to be large and bulky. Consequently because of the higher power requirement in a centralised set up, the primary switch and the filtering capacitors sizes also go up. Such an overall need for bulky components renders the centralised power supply architecture to consume more space than a distributed power supply architecture. Distributed power supply architecture on the contrary requires smaller discrete components that make the design more compact. Even though six pieces of transformers and switches are required, the dimensions of each of the components tend to be small.

Another disadvantage of using a centralised architecture is the increased complexity in layout. With the isolated power supply rails emerging from the same transformer it is hard to place all the gate drivers nearby. Longer tracks are required to connect the secondary windings of the transformer to the gate driver power supply pins. Such complexities in PCB routing add to the design effort. Importantly, the unnecessary increased track lengths and multiple windings within a single transformer result in poor EMI performance and noise coupling among the channels. One benefit of a distributed power supply architecture is that the transformers and the primary switch can be placed near the individual gate drivers. This minimises the overall track lengths and enhances the ease of PCB routing. The distributed architecture results in better EMI characteristic and a compact design.

Figure 3: Distributed power architecture using a single transfomer with two separate windings to generate the isolated power supply. (The components marked in red are available in Rohm‘s product portfolio)

Gate drivers with integrated flyback controllers:

Rohm has a series of automotive qualified (AEC-Q100) gate drivers with in-built flyback controller function. All the gate drivers in this series are isolated at 2.5kVrms with coreless transformer technology. These gate drivers are also robust with a common mode transient immunity of 100V/ns and suitable for platforms involving IGBT and SiC MOSFETs. A simple distributed power supply can be generated by using very few additional components and placing a small transformer close to the gate driver IC. Since the flyback controller is integrated within the gate driver, external controller ICs are not required.

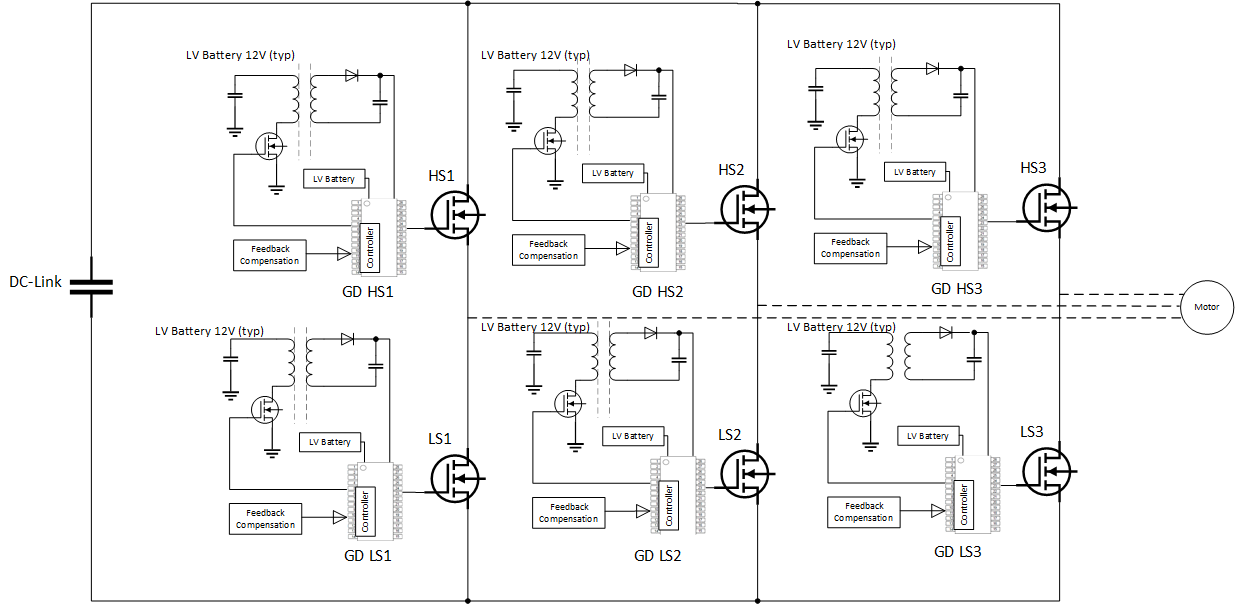

A simple block diagram using isolated gate driver with integrated flyback controller is shown in Figure 4. To generate an isolated power supply using gate drivers with flyback controllers, a simple transformer, primary switch and filters are necessary. The additional feedback and compensation network is needed for the current mode control of the in-built controller. The feedback circuit can be easily realised by using an auxiliary winding from a transformer and resistive dividers. The flyback controller that is integrated in the gate driver IC itself also has several built-in protection functions that ensures safe operation of both flyback converter and the gate driver itself. These protection features are under-voltage lock out, over-voltage protection, over-current protection, a soft-start up function and adjustable switching frequency.

Figure 4: Distributed power supply architecture, showing Rohm gate drivers with integrated flyback controller

The gate drivers with built-in flyback controller in this example have a wide input logic supply voltage range. In conventional isolated gate drivers, a supply of maximum 5.5V is possible to drive the logic block. The gate drivers with integrated flyback controller are able to accept a voltage range of 4.0 to around 32V (and 8.0 to around 24V in some cases). The low voltage battery (typically 12V) used in a battery EV or PHEV, for example, can be directly connected to the gate driver IC without the need for additional circuits to generate a 5.0V supply.

Isolated gate drivers with integrated flyback controller such as the BM60052AFV-C (4.0 to ̴ 32V), BM60054AFV-C (4 to ̴ 32V), BM60055AFV-C (4.5 to ̴ 30V), BM60059AFV-C (4.5 to ̴ 24V), and BM60060AFV-C (8.0 to ̴ 24V), are all automotive-qualified. These gate drivers have been constructed for easy adaption to SiC based and IGBT based platforms.

Summary

A distributed isolated power supply architecture using gate drivers with integrated flyback function offers many design level benefits such as compact design, ease of PCB layout/routing and better EMI characteristics. Gate drivers with several integrated protection functions can ensure safe system level operation in power management systems for e-powertrain and other new and emerging applications.

About the authors:

Vikneswaran Thayumanasamy is application engineer for Gate Drivers at Rohm Semiconductor Europe and Kevin Lenz is application marketing manager for E-Powertrain at Rohm Semiconductor Europe