Meet the transient power challenge

It is possible to use mix and match power components to create customised units that are adaptable to a range of energy sources and load requirements while optimising the power sub-system for size, weight, and power, agues Chester Firek, Vicor.

Few classes of electronic apparatus make demands as challenging to system power sources as RF transmitters. In today’s systems virtually all transmission signals carry digitally encoded information as bursts of data encoded with complex modulation techniques.

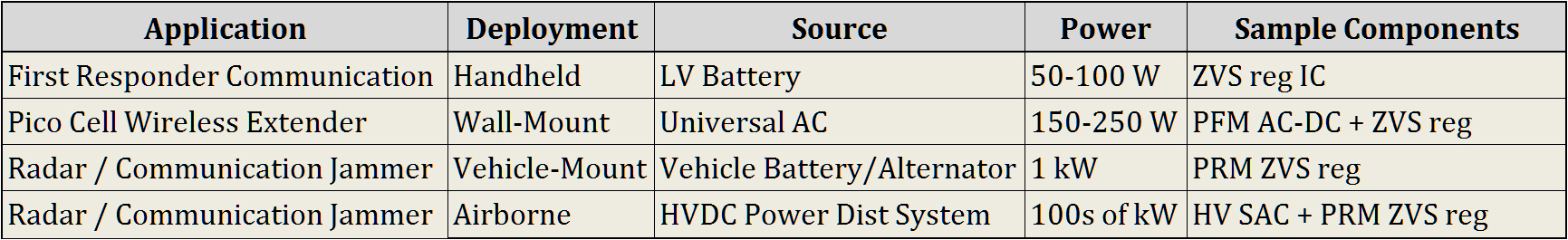

The application sectors for these systems can broadly be divided into three main areas. At the high-power end are radars and military RF-jamming systems. These range from ground-vehicle deployed systems with outputs on the order of 1kW to aircraft-mounted jammer arrays with total output power extending into the hundreds of kW.

Application areas

Lower-power RF applications can be equally demanding of their power sources, particularly with regard to current dynamics and output voltage stability during steep current-waveform transitions. Examples include communications systems for first-responder emergency personnel. Handheld radios powered by small NiMH or LiFePO4 batteries, vehicle-mounted sets powered by traditional lead-acid batteries and vehicle-based alternators, and command-centre systems operating from marginally regulated AC generators exemplify the range of raw energy sources operating in this application.

A third, growing, segment includes wireless-telephone LTE picocells and WiFi access points for public spaces.

Of these three examples, the picocell and WiFi access points face the greatest data demand and, correspondingly, the highest RF channel density. High data demand derives not only from the number of potential users but also from trends in data consumption as traffic shifts from static web pages and data access to streaming video. Picocells demand low-distortion transmission characteristics, which are critical to maximising a site’s bandwidth utilisation, connection count and data throughput.

Power technologies

Designers choose different semiconductor technologies to implement the RF power amplifier - the final active stage that drives the transmitting antenna - depending on a transmitter’s operating spectrum and output power. Different output stage criteria suggest either silicon or various compound-semiconductor technologies, each presenting its own power-supply requirements.

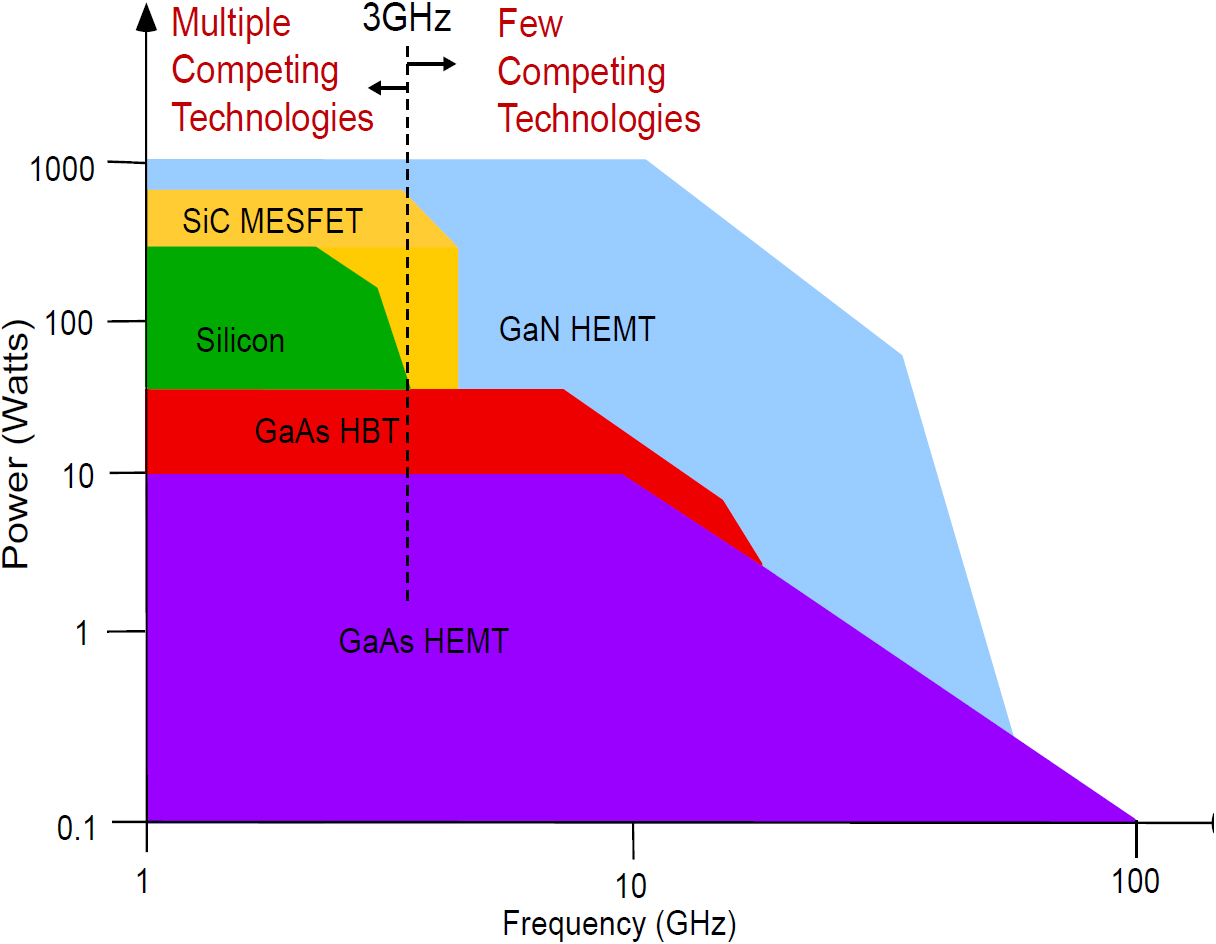

Figure 1: Five semiconductor technologies compete for RF power-amplifier sockets. (graphic: courtesy RFMD)

Power-amplifier designs currently deployed use silicon LDMOS transistors, Silicon Carbide (SiC) MESFETs, Gallium Arsenide (GaAs) HEMTs, GaAs HBTs and Gallium Nitride (GaN) HEMTs (Figure.1) semiconductor technologies. Of these, GaN perhaps shows greatest promise at high frequencies and high power.

For many years, GaAs devices dominated RF power-amplifier designs, but now faces several competing alternatives, particularly for systems operating at 3GHz or lower. Here, LDMOS, and fabrication technologies such as SoI (silicon-on-insulator), are compatible with high-volume fabrication processes and enjoy economies of scale not yet available to compound-semiconductor technologies.

Existing GaAs transmitter designs in space-constrained applications can often benefit from upgrades to one of the alternative semiconductor technologies. Typical GaAs devices exhibit efficiencies of about 45%. In contrast, GaN transmitters, deliver efficiencies of 50 to 70%.

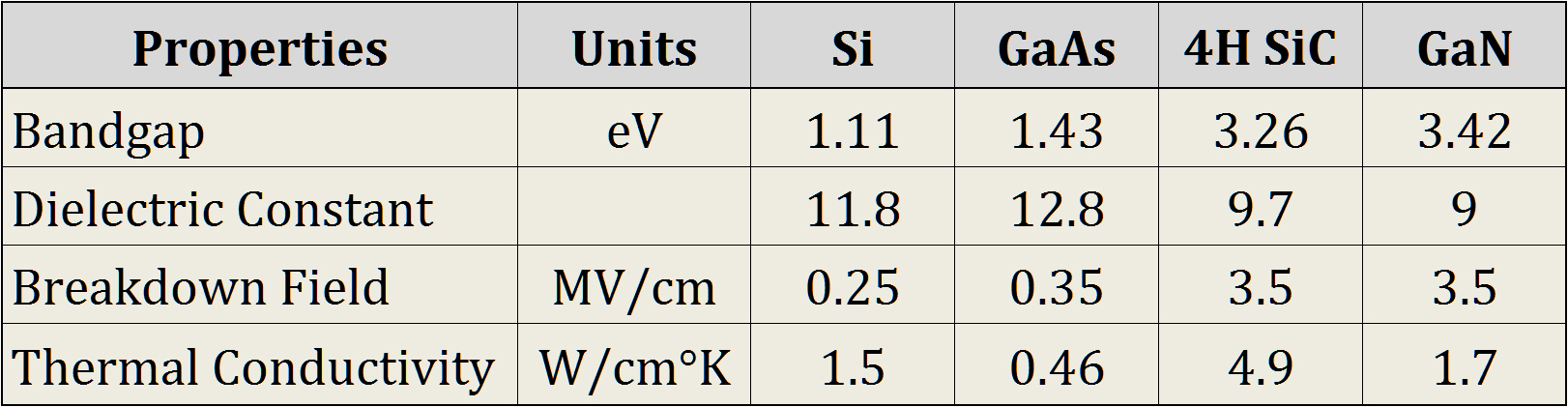

Table 1: Properties of semiconductor technologies common in RF applications

The newer compound semiconductor technologies also exhibit substantially higher breakdown field strength than Si or GaAs, enabling the support of high-voltage high-frequency device designs (Table 1). For example, it is now common to find GaN power amplifiers that operate at a VDS almost twice that of typical GaAs power amplifiers and, with better efficiency, deliver higher RF power density. The thermal conductivity of GaN is more than three times that of GaAs, further easing cooling requirements and facilitating smaller and lighter system designs for a given output power.

As GaN technologies ramp up, some designs take advantage of its properties by using cascaded stages, such as a GaAs driver followed by a GaN power-amplifier stage. This combination can simplify upgrading designs to take advantage of the newer technology, but also complicates the power subsystem design.

Output power requirements

RF applications often give rise to compatible systems operating from disparate raw energy sources, including small batteries for handheld devices, HVDC for airborne systems, and universal AC inputs for fixed-location systems. Depending on application, RF output power can range over five or six orders of magnitude. Output power, bandwidth, and functional density requirements drive power-amplifier technology selection, which in turn determines the transmitter’s supply voltage requirement.

Despite the large range of possible input and output voltages and output currents, many RF applications have similar power-subsystem requirements. As a result, these systems benefit from certain shared power-converter attributes. Key among these is the power sub-system’s transient response to high dI/dt load-current steps.

There are several ways of approaching power-sub-system design for RF applications. One separates the power block into two sub-sections: one that accommodates the voltage characteristics of the energy source and the other that satisfies requirements imposed by the load, particularly the RF power amplifier.

Designers can quickly mix and match modular building blocks to accommodate different power-amplifier technologies, power levels, or power-source characteristics.

A modern RF system transmits in bursts. Although the transmitted signal may be an encoding of digital data, the encoded signal is analogue in nature. Rapid perturbations in amplitude within the signal envelope’s bandwidth can manifest as signal-distortion products and degrade the quality of the transmission channel. Such degradation can result in lost data packets effectively reducing data throughput or data rates insufficient for applications such as video streaming.

Burst-mode transmission systems therefore demand high waveform fidelity while drawing high transient currents from the power sub-system. During rapid current-waveform transitions, the power sub-system must limit the output-voltage perturbation. Residual output-voltage disturbances can appear as a variation in the RF signal output with little attenuation.

Brute-force methods of stiffening the output voltage, such as adding bulk capacitance, are usually inefficient when load currents exhibit large and rapid transitions (high dI/dt). However, ultra-low ESR capacitors that can supply high dI/dt loads offer poor volumetric density. Correspondingly, high-K dielectrics provide large capacitances in small volumes, but with higher ESR and resultant slower response times to steps in load current.

A more effective approach is to start with power-converter architectures that inherently exhibit low AC output impedances. Power trains that operate at high switching frequencies and provide cycle-by-cycle regulation minimise a converter’s dependence on bulk capacitors and their AC characteristics.

Designs that require modest output power, such as picocells and similar applications, can “right size” the power train’s output capability to accommodate load-current peaks. Combined with inherently low-noise control methods, such as zero-voltage switching, power-output stages can minimise dependence on bulk capacitance to supply current transients.

Power-train topologies such as Sine-Amplitude Converters (SACs) provide voltage transformation. Examples of SAC-based power-train components include Vicor’s VTM current multiplier, which can provide up to 130A at efficiencies of up to 96%. The Vicor Power Component Design Methodology allows power developers to combine power components to address a range of applications and deployments with minimum power-sub-system design time (Table 2).

Table 2: RF applications and sample power-train components

PCIM 2015: Hall 9 - 535